Molecular sieve oxygenerator and molecular sieve device thereof

A technology of molecular sieves and oxygen generators, applied in the field of oxygen generators, can solve the problems of difficult replacement of molecular sieve systems and high scrap costs, and achieve the effects of reducing noise and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

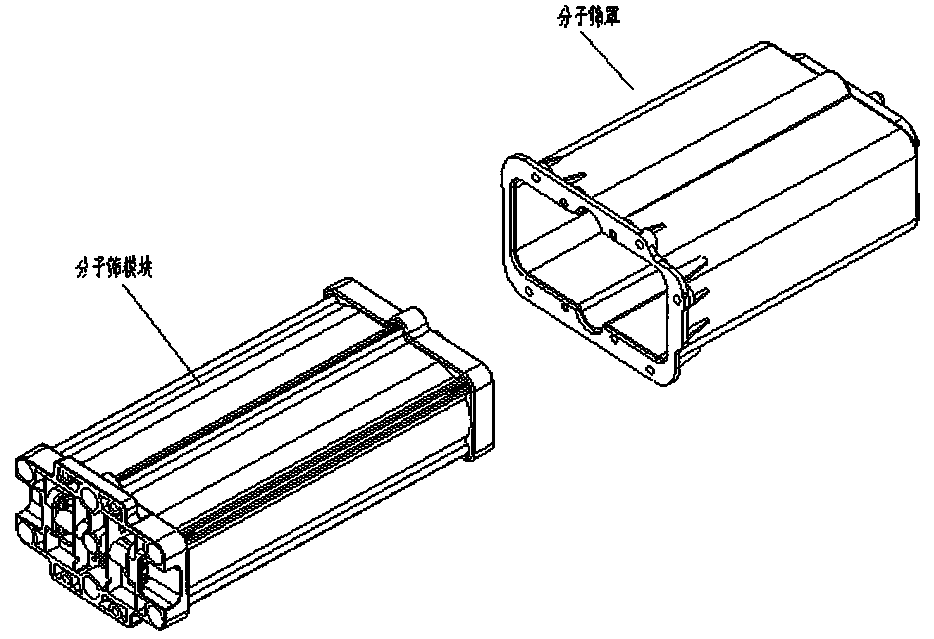

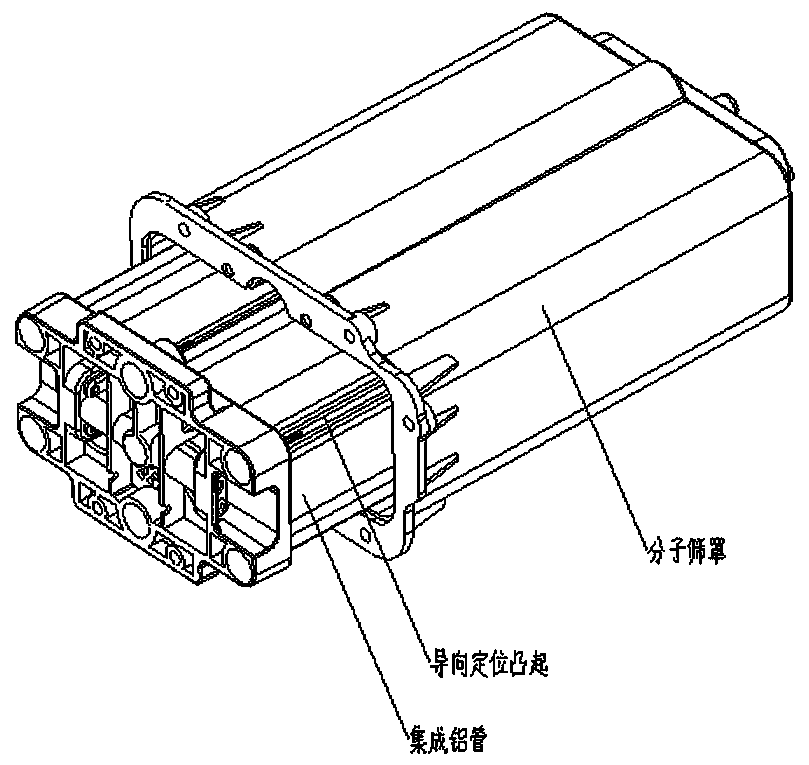

[0024] A molecular sieve device, such as figure 1 , figure 2 As shown, it includes a cylindrical molecular sieve cover with an opening at one end. An installation structure is provided at the opening end of the molecular sieve cover. An adapter plate is provided outside the bottom of the molecular sieve cover cylinder. The adapter plate is fixedly connected to the molecular sieve cover. Inside the molecular sieve cover cylinder, there is a The molecular sieve module is detachably connected with the molecular sieve cover. The outer surface of the molecular sieve module is provided with guiding and positioning protrusions, and the inside of the molecular sieve cover is provided with a guide chute that cooperates with the guiding and positioning protrusions. The molecular sieve module and the molecular sieve cover form a detachable connection through the guiding positioning protrusions and the guiding chute. The sliding connection of the hood helps to keep the loading and unloa...

Embodiment 2

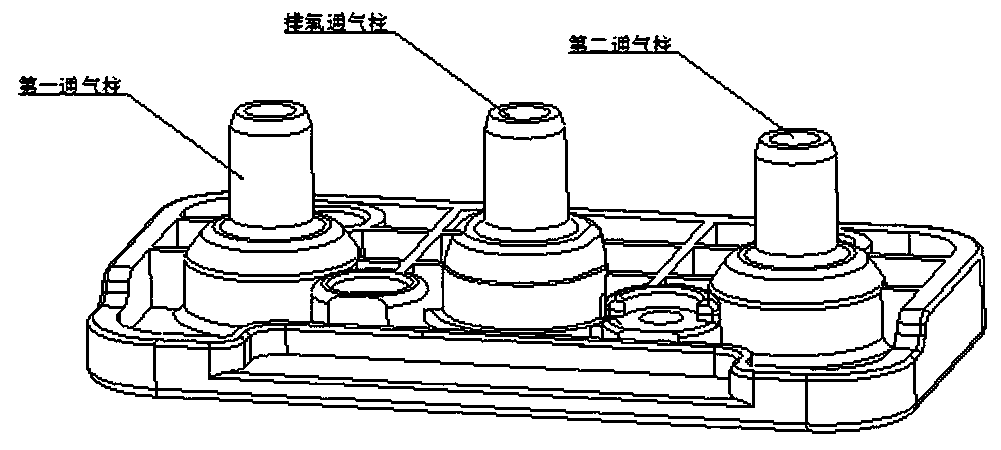

[0028] A molecular sieve oxygen generator, such as Figure 6 , Figure 7 As shown, it includes a housing, a molecular sieve device and a control system for controlling the oxygen generator. The casing is provided with a disassembly port, and a chamber for installing the molecular sieve device is arranged in the disassembly port, and the molecular sieve device is arranged in the cavity, and can be disassembled through the disassembly port. The molecular sieve device includes a cylindrical molecular sieve cover with one end open, and an installation structure is arranged at the opening end of the molecular sieve cover, and the molecular sieve cover is fixedly connected with the cavity of the oxygen generator through the installation structure at the open end. The control system includes a controller, a compressor and a solenoid valve, the controller is electrically connected to the coil of the solenoid valve, and the air outlet of the compressor is connected to the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com