Method capable of improving bioleaching efficiency of valuable metals in waste printed circuit boards

A technology for printed circuit boards and valuable metals, which is applied in the field of improving the bioleaching efficiency of valuable metals in waste printed circuit boards, can solve the problems of low leaching rate, slow bioleaching rate, and long time consumption, and achieve increased leaching efficiency, combined The effect of strong ability and moderate molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

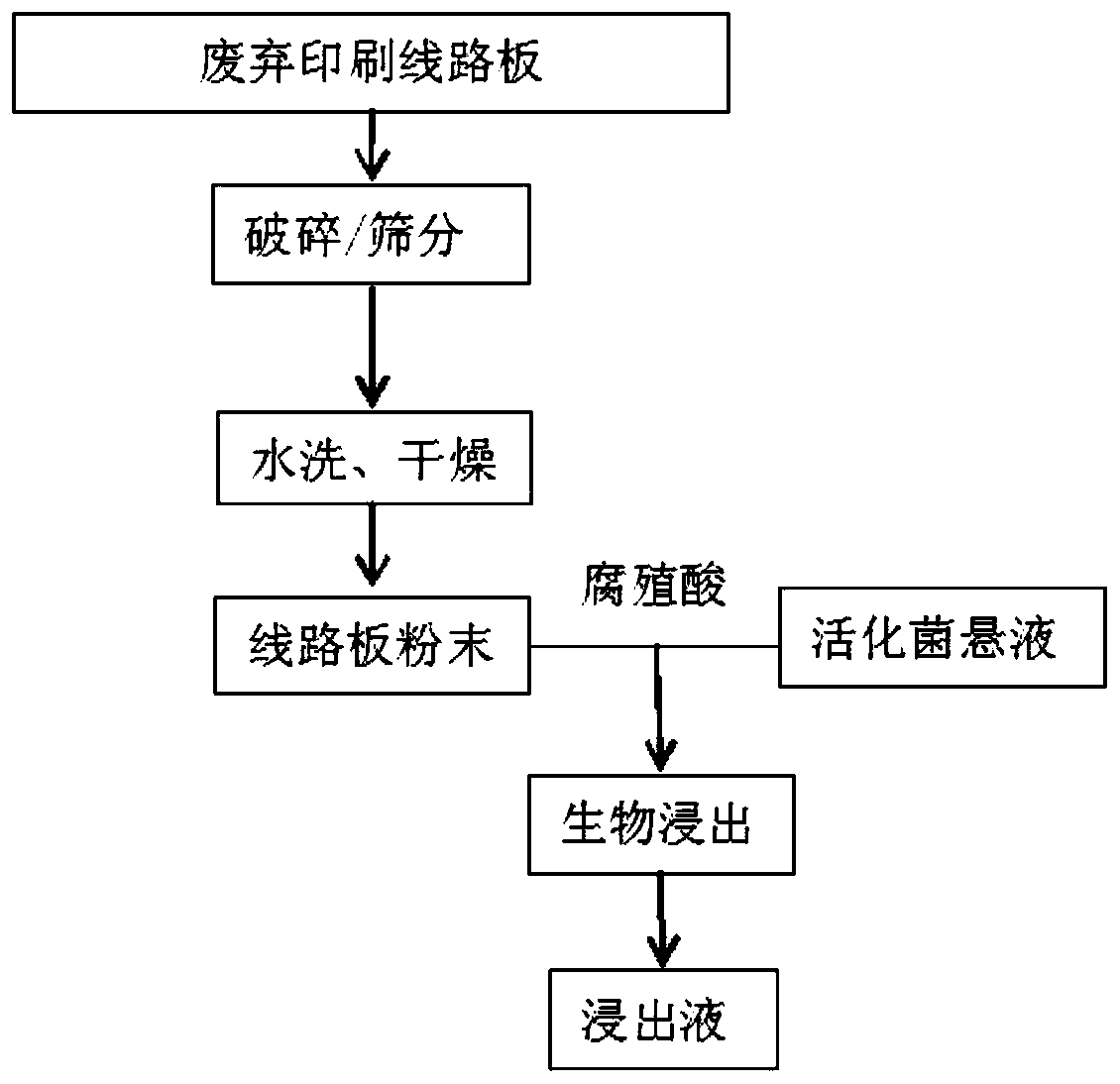

[0024] A method for improving the bioleaching efficiency of valuable metals in waste printed circuit boards, the process flow chart is as follows figure 1 shown, including the following steps:

[0025] (1) Broken

[0026] Crushing the waste printed circuit boards to make the particle size ≤0.25mm; washing and sorting and drying.

[0027] (2) Bacterial activation:

[0028] Ferroplasma acidophilus, Thiobacillus ferrooxidans and Thermobacterium acidophilus were prepared in a volume ratio of 1:2:3 to make mixed acidophilic bacteria, and the mixed acidophilic bacteria were activated with 9K medium, and the inoculation ratio was 10 %(V / V), the culture temperature is 45°C, the rotation speed is 170r / min, and the culture time is 24h to form a bacterial suspension;

[0029] The bacterial suspension was transferred to an Erlenmeyer flask containing 9K medium at 10% (V / V), and placed in a constant temperature shaking shaker with a temperature of 45°C and a rotation speed of 170r / min f...

Embodiment 2

[0033] A method for improving the bioleaching efficiency of valuable metals in waste printed circuit boards, comprising the following steps:

[0034] (1) Broken

[0035] Crushing the waste printed circuit boards to make the particle size ≤0.25mm; washing and sorting and drying.

[0036] (2) Bacterial activation:

[0037] Ferroplasma acidophilus, Thiobacillus ferrooxidans and Thermobacterium acidophilus were prepared in a volume ratio of 1:2:3 to form a mixed acidophilus, and the mixed acidophilus was activated with 9K medium, and the inoculation ratio was 20 %(V / V), the culture temperature is 30°C, the rotation speed is 90r / min, and the culture time is 48h to form a bacterial suspension;

[0038] The bacterial suspension was transferred to an Erlenmeyer flask containing 9K medium at 15% (V / V), and placed in a constant temperature shaking shaker with a temperature of 40°C and a rotation speed of 150r / min for 30h to form an activated bacterial liquid. The density of microscop...

Embodiment 3

[0042] A method for improving the bioleaching efficiency of valuable metals in waste printed circuit boards, comprising the following steps:

[0043] (1) Broken

[0044] The waste printed circuit boards are crushed to make the particle size ≤0.25mm; after washing and sorting, put them into the drying box for drying.

[0045] (2) Bacterial activation:

[0046] Ferroplasma acidophilus, Thiobacillus ferrooxidans and Thermobacterium acidophilus were prepared in a volume ratio of 1:2:3 to make mixed acidophilic bacteria, and the mixed acidophilic bacteria were activated with 9K medium, and the inoculation ratio was 15 %(V / V), the culture temperature is 40°C, the rotation speed is 150r / min, and the culture time is 30h to form a bacterial suspension;

[0047] The bacterial suspension was transferred to an Erlenmeyer flask containing 9K medium at 20% (V / V), and placed in a constant temperature shaking shaker with a temperature of 30°C and a rotation speed of 90r / min for 48h to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com