Digital printing process for chenille floor mat with natural gradient effect

A gradient effect, chenille technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of difficult control of infrared fixing process, easy to burn fluff, limited pattern and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

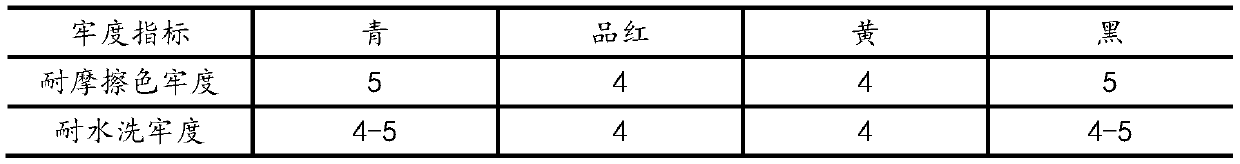

Examples

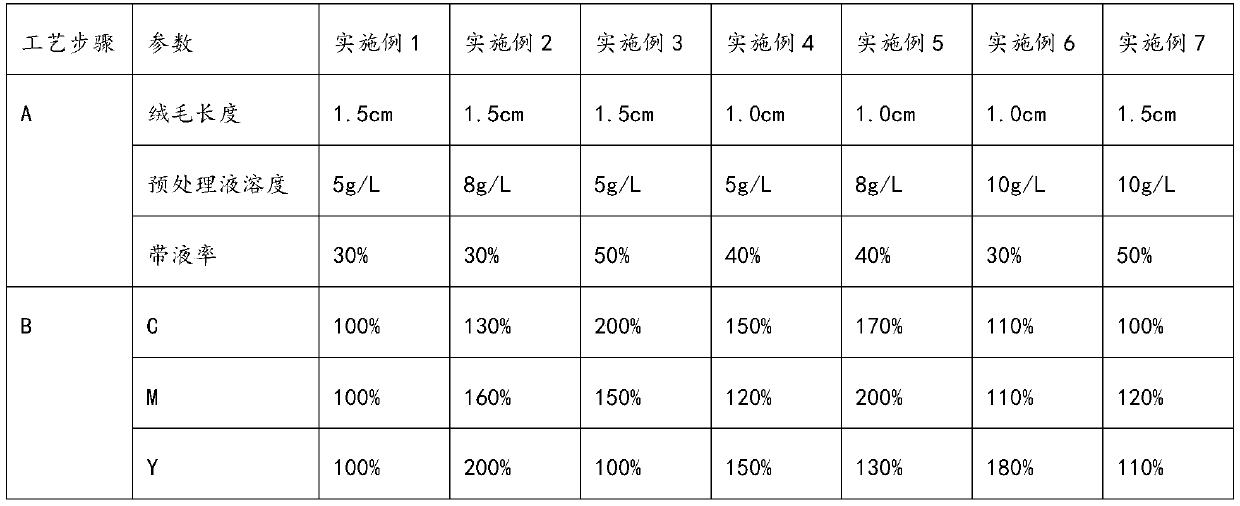

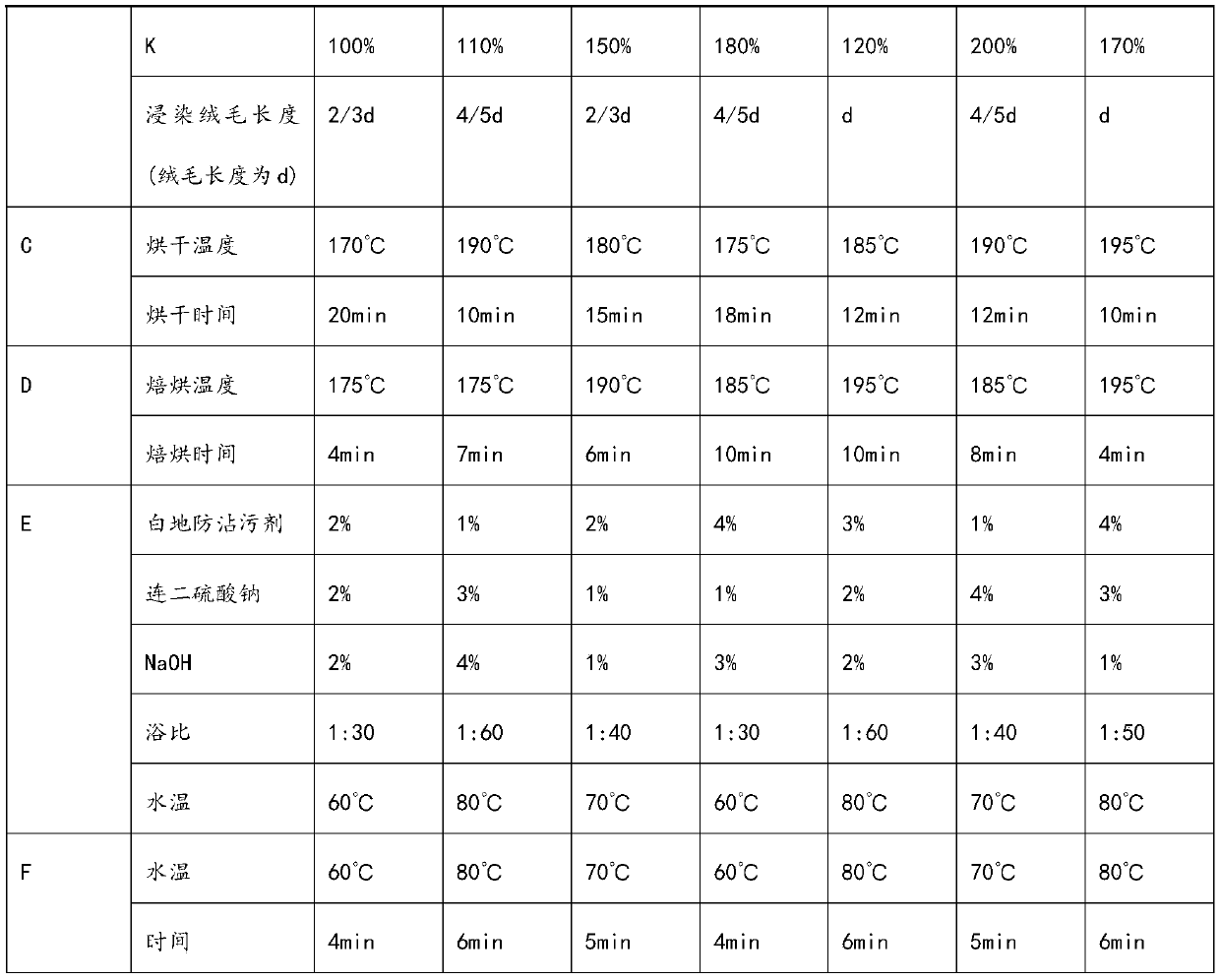

Embodiment 1

[0040] This embodiment discloses a digital printing process for a chenille floor mat with a natural gradient effect. The grey cloth used for digital jet printing includes basic and tufted piles formed on the base cloth and evenly distributed, wherein the length of the pile refers to the top of the pile To the length between the base cloth, the longer side of the pile is the front of the chenille mat, and the side with the shorter pile is the back of the chenille mat. The pile length of the grey cloth used in this example was 1.5 cm.

[0041] This embodiment includes the following steps:

[0042] A, preprocessing;

[0043] To prepare a pretreatment solution, dissolve the TF-620 purchased from Zhejiang Transfar Group in water to make a pretreatment solution with a concentration of 5g / L;

[0044] Place the chenille mat with the short fluff side up, and spray the pre-treatment liquid on the back of the grey fabric; the pre-treatment liquid spreads from the short end of the fluff...

Embodiment 2

[0070] The steps in this example are the same as those in Example 1, and the differences in process parameters are shown in Table 2. The chenille floor mats are prepared for rubbing color fastness testing and washing fastness. The test methods and standards are the same as those in Example 1. , the specific test results and sensory effects are shown in Table 3.

Embodiment 3

[0072] The steps in this example are the same as those in Example 1, and the differences in process parameters are shown in Table 2. The chenille floor mats are prepared for rubbing color fastness testing and washing fastness. The test methods and standards are the same as those in Example 1. , the specific test results and sensory effects are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com