Dust suppression method of slope excavation

A technology for reducing dust and slopes, applied in cleaning methods, road surface cleaning, construction, etc., can solve problems such as limited effects and no better control methods, and achieve the effects of improving construction efficiency, good dust reduction effects, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

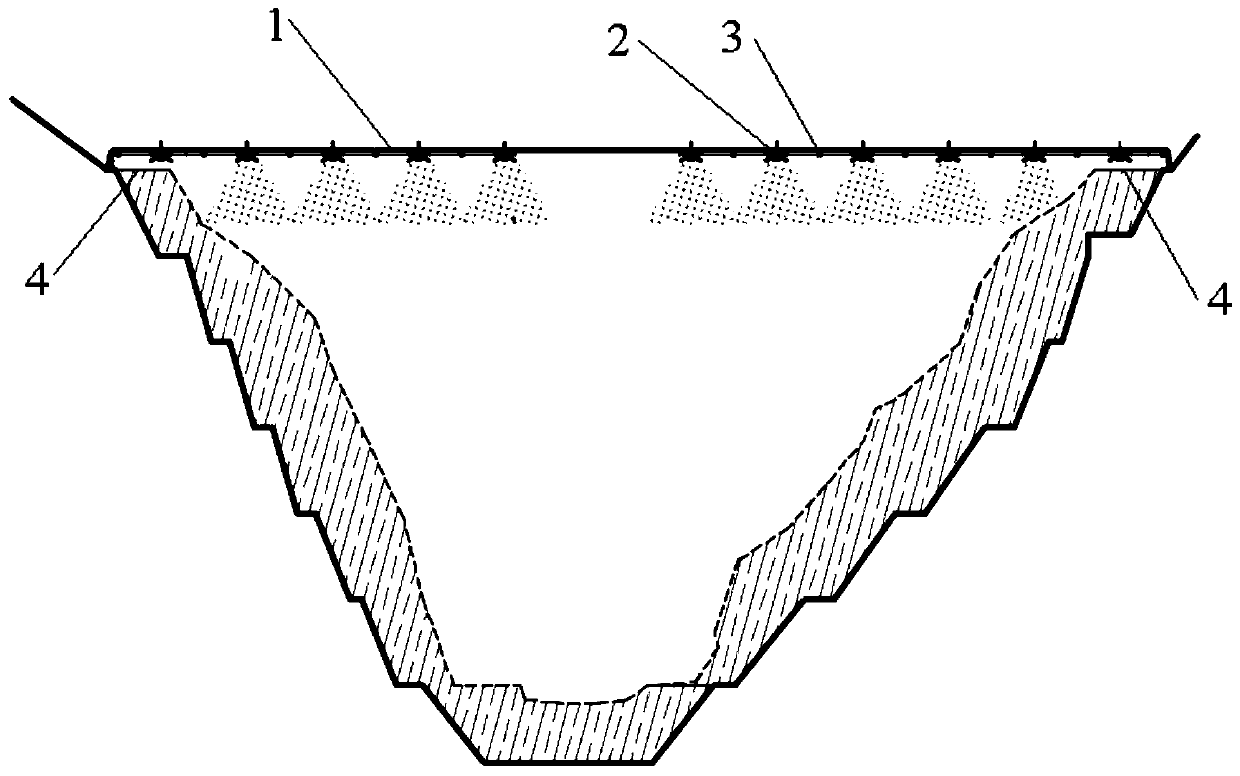

[0022] Such as figure 1 As shown, the specific implementation and application of the present invention in the construction of a certain hydropower station, the abutment span of the two sides of the hydropower station construction is 450m~520m, the excavation height of the side slope is about 239m, the slope is 45°~69°, and the excavation of the side slope The final gravel cannot be shipped directly. A large amount of gravel needs to be thrown from the working surface to the scum sill set up on the river bed slope, and then carried out for secondary shipment. The excavation length of each level of bridleway is 150m, and the excavation area is large. , if the traditional dust suppression method is adopted, the number of personnel and equipment required will be very large, and the economic cost will increase.

[0023] Adopt the method for side slope excavation dust reduction of the present invention, concrete steps are as follows:

[0024] Step 1. Weld a 14mm thick steel plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com