Gradual solidification forming method for large steel ingot or steel billet

A solidification forming and steel ingot technology, which is applied in the field of metal material forming, can solve the problems of high risk of steel ingots and low metal utilization rate, and achieve the effects of fast solidification speed, short production cycle and high metal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

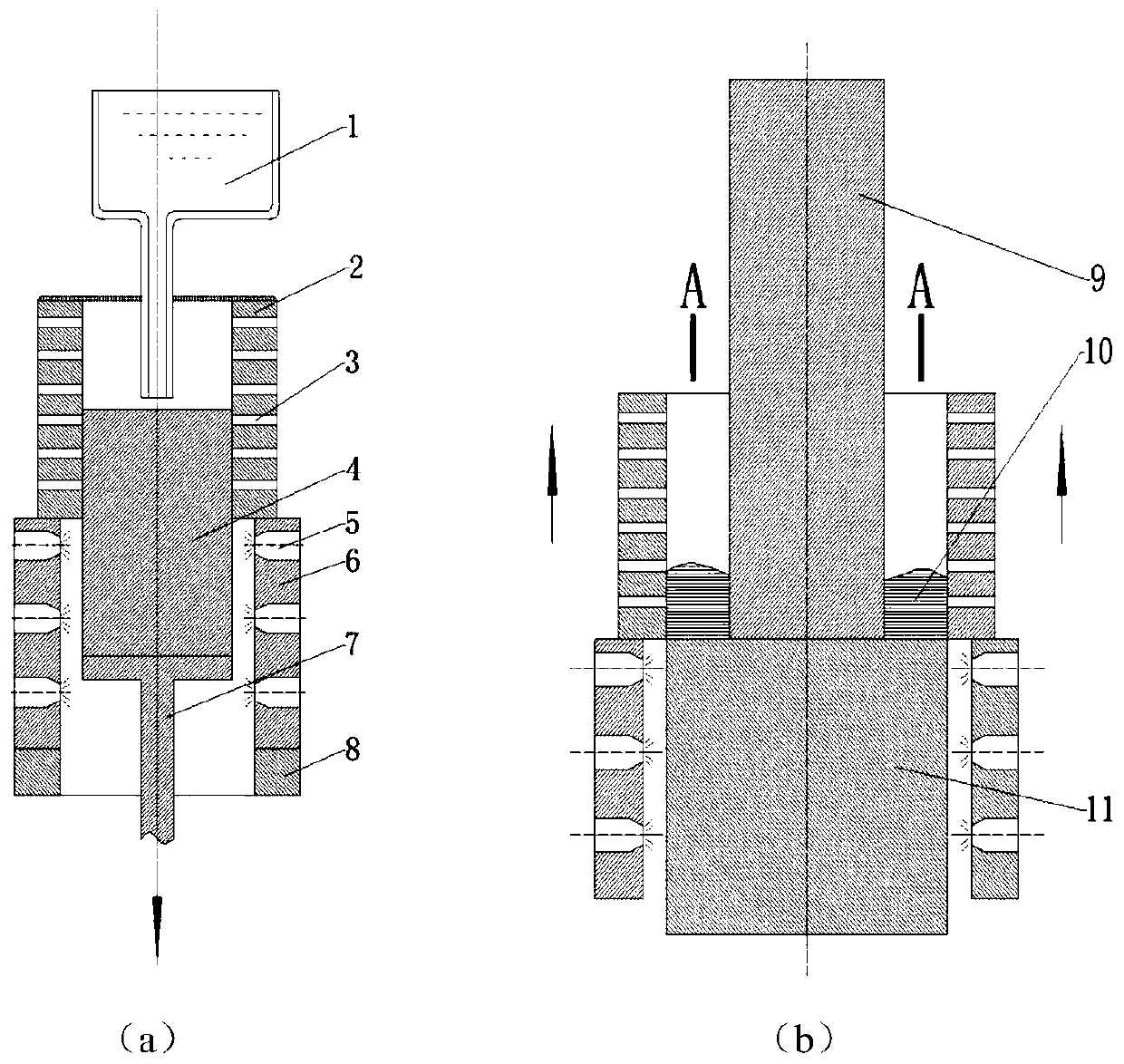

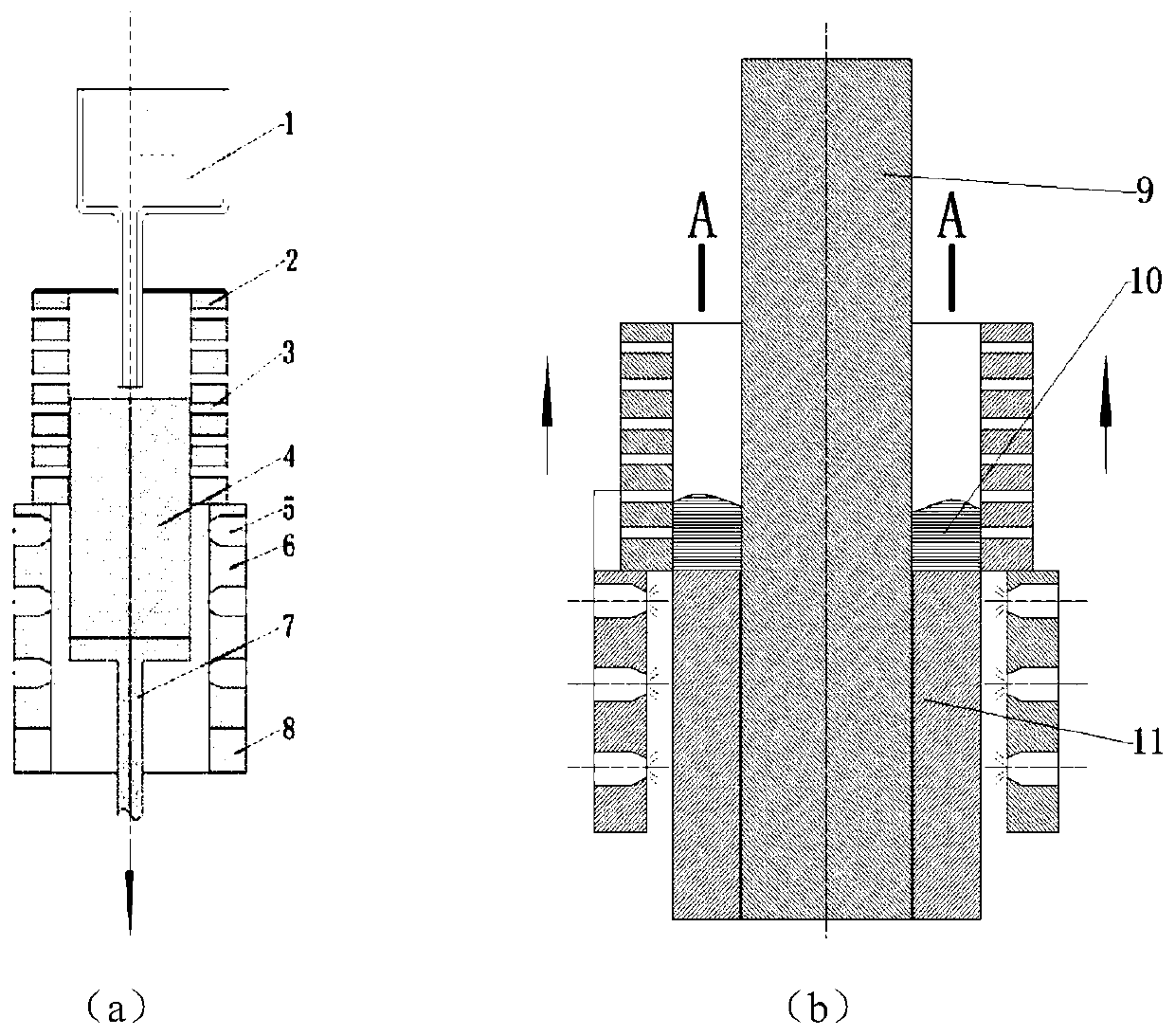

[0021] A progressive solidification forming method for large steel ingots or billets. The key to this method is: the molten metal is poured into crystallizers of different sizes with ladles of different tonnages for solidification, and the steel ingots solidified in the previous step become solidified in the next step The axis of the core is gradually solidified and accumulated in a cycle to form a steel ingot of the target size. The specific steps are:

[0022] 1. The molten metal is poured into the crystallizer with a small bag through the nozzle, and the molten metal in the crystallizer is initially solidified by the action of the water-cooled crystallizer, and the metal billet is pulled out of the crystallizer with a dummy device, and then sprayed with water to cool it until it is completely solidified;

[0023] 2. Expand the radial size of the crystallizer, and place the steel ingot solidified in the first step (called the initial ingot core) at the center of the enlarged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com