Self-supporting die table production line for prestress plate production

A prestressed, self-supporting technology, used in ceramic molding machines, manufacturing tools, ceramic molding linings, etc., can solve the problems of rising equipment costs, inability to shift, and corporate burdens, reducing transportation costs, improving standardization, The effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

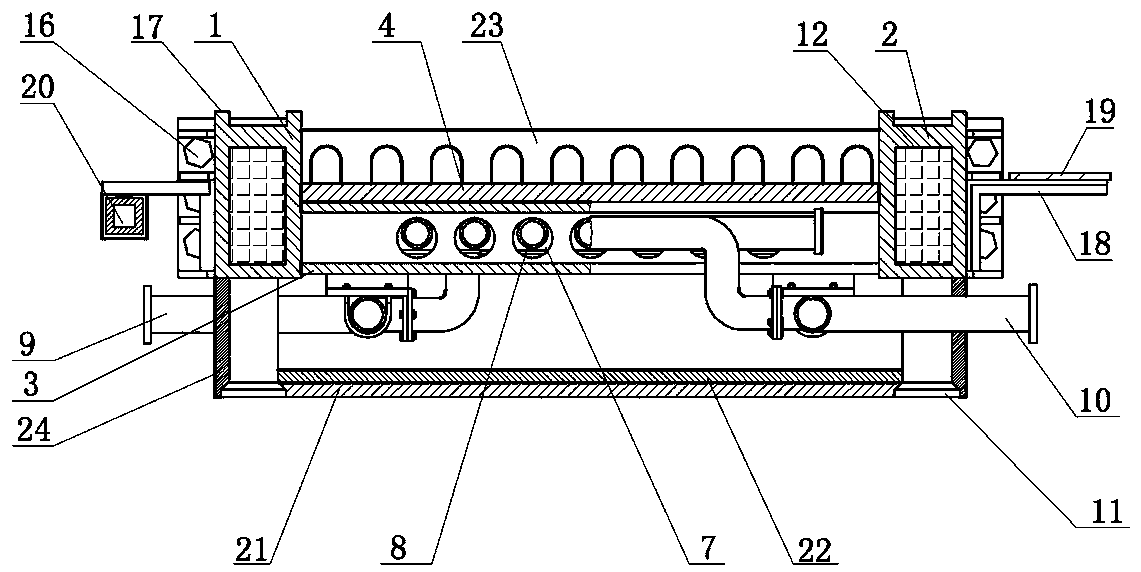

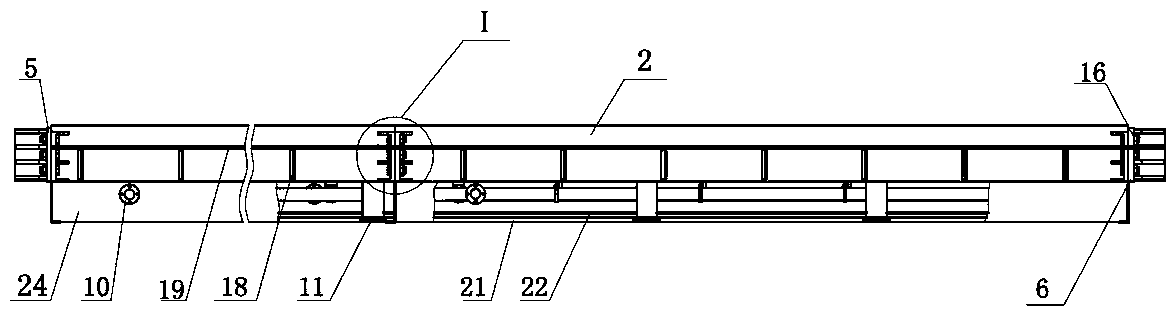

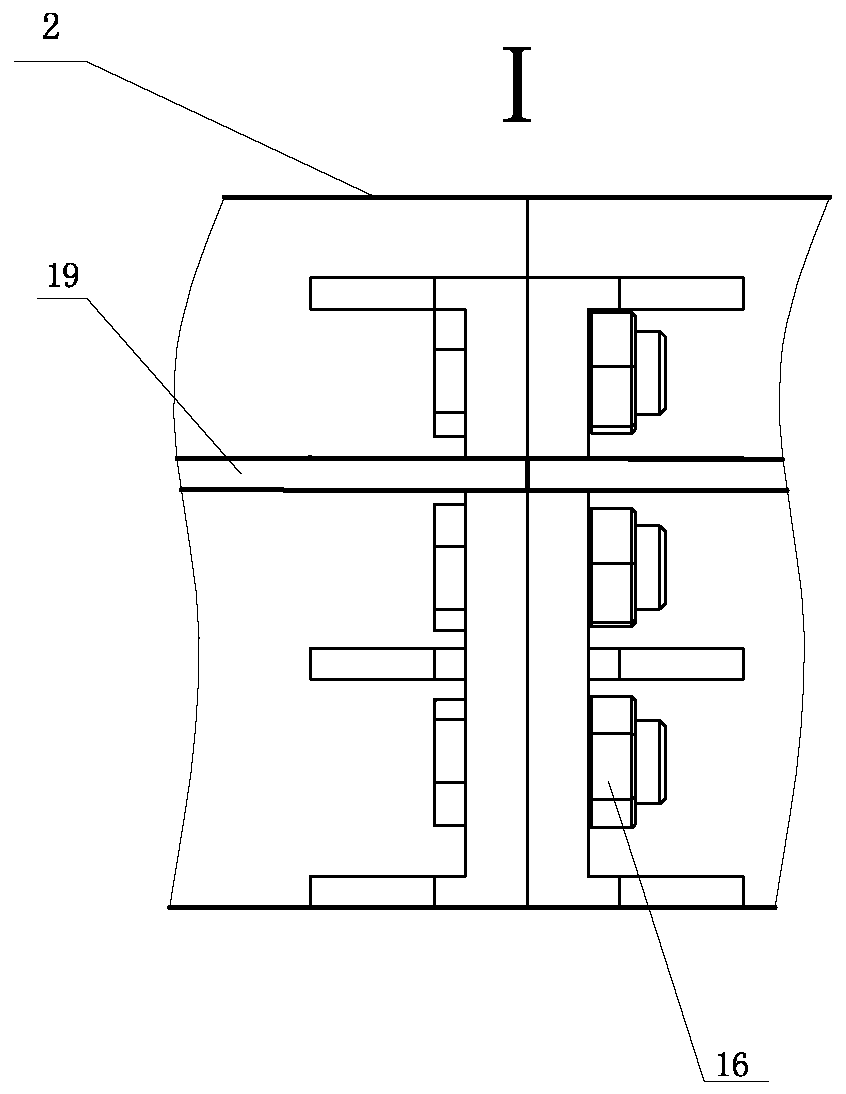

[0011] The self-supporting formwork production line for prestressed panel production according to the present invention includes a first side beam 1 and a second side beam 2 parallel to each other, and the first side beam 1 and the second side beam 2 are connected by several beams 3 , the bottom of the first side beam 1 and the second side beam 2 or the cross beam 3 is equipped with a leg 11, the upper side of the cross beam 3 is provided with a platform plate 4, and the platform plate 4 is located in the middle of the first side beam 1 and the second side beam 2 in the height direction, The bottom surface of the platform slab 4 is in contact with the top surface of the crossbeam 3, the first steel bar tensioning platform 5 and the second steel bar tensioning platform 6 are respectively installed at the two ends of the first side beam 1 and the second side beam 2, and several transverse beams 3 are provided on each crossbeam 3. The through hole 7 of the through hole 7 is pierce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com