Novel prefabricated direct-buried polyurethane spraying heat-preservation pipe production line and production process

A prefabricated direct burial, production process technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of difficult detection, uneven density inside the polyurethane layer, many voids, etc., to avoid high manufacturing costs and improve products. quality, the effect of improving the cladding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

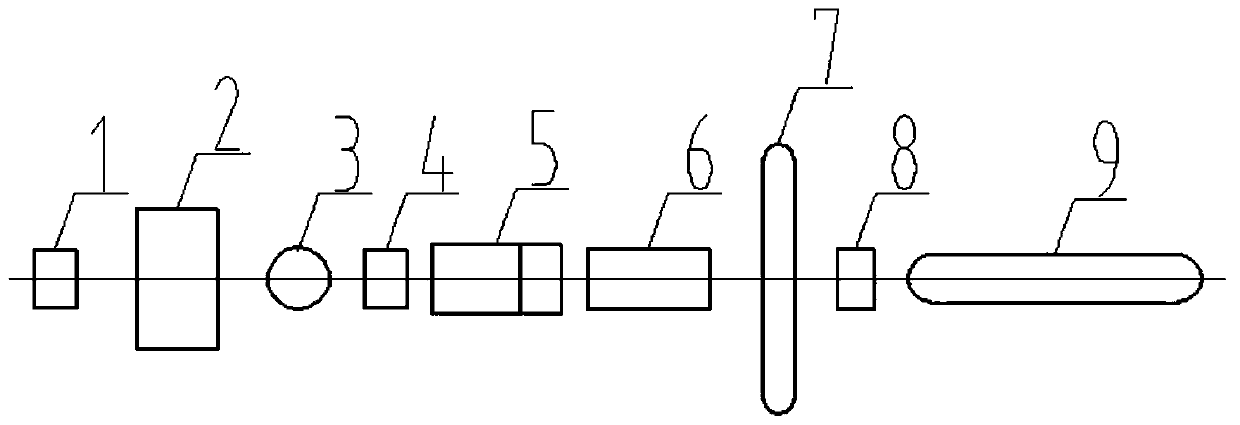

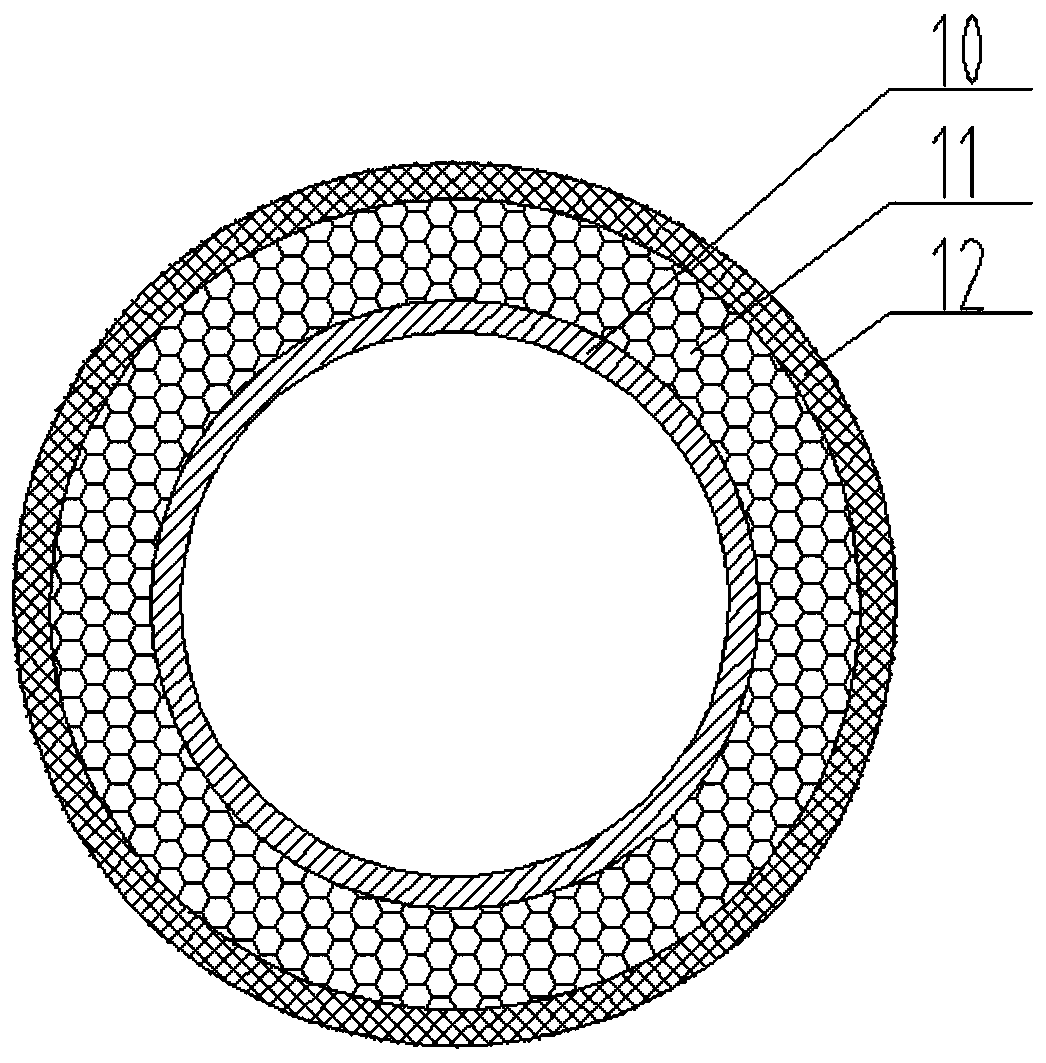

[0035] A new type of prefabricated direct-buried polyurethane spray insulation pipe production line, see figure 1 , figure 2 , the production line consists of a flame preheating furnace 1, a shot blasting derusting machine 2, a pipe purging device 3, a polyurethane spraying system 4, a polyurethane layer rounding device 5, a polyurethane curing platform 6, and a polyethylene winding system 7 arranged in sequence , coating cooling system 8 and pipe end processing device 9, through a new type of prefabricated direct-buried polyurethane spray insulation pipe production line of the present invention, the industrial automatic production of polyurethane insulation pipes is realized, which not only reduces labor intensity, but also improves production efficiency .

[0036] A new type of production process for prefabricated directly buried polyurethane spray insulation pipes, the process includes the following steps:

[0037] Preheating: Preheat the welded pipe through the flame pr...

Embodiment 2

[0048] A new type of prefabricated direct-buried polyurethane spray insulation pipe production line, see figure 1 , figure 2 , the production line consists of a flame preheating furnace 1, a shot blasting derusting machine 2, a pipe purging device 3, a polyurethane spraying system 4, a polyurethane layer rounding device 5, a polyurethane curing platform 6, and a polyethylene winding system 7 arranged in sequence , coating cooling system 8 and pipe end processing device 9, through a new type of prefabricated direct-buried polyurethane spray insulation pipe production line of the present invention, the industrial automatic production of polyurethane insulation pipes is realized, which not only reduces labor intensity, but also improves production efficiency .

[0049] A new type of production process for prefabricated directly buried polyurethane spray insulation pipes, the process includes the following steps:

[0050] Preheating: Preheat the welded pipe through the flame pr...

Embodiment 3

[0061] A new type of prefabricated direct-buried polyurethane spray insulation pipe production line, see figure 1 , figure 2 , the production line consists of a flame preheating furnace 1, a shot blasting derusting machine 2, a pipe purging device 3, a polyurethane spraying system 4, a polyurethane layer rounding device 5, a polyurethane curing platform 6, and a polyethylene winding system 7 arranged in sequence , coating cooling system 8 and pipe end processing device 9, through a new type of prefabricated direct-buried polyurethane spray insulation pipe production line of the present invention, the industrial automatic production of polyurethane insulation pipes is realized, which not only reduces labor intensity, but also improves production efficiency .

[0062] A new type of production process for prefabricated directly buried polyurethane spray insulation pipes, the process includes the following steps:

[0063] Preheating: Preheat the welded pipe through the flame pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com