Rapid feeding and conveying device for ampoule bottle box supports

A technology of conveying device and ampoule bottle box, which is applied in packaging and other directions, can solve the problems of lowering printing, adding expenses and entering the tray, low box tray supply and conveying efficiency, low box tray supply efficiency, etc., so as to reduce labor costs and improve The effect of supply efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

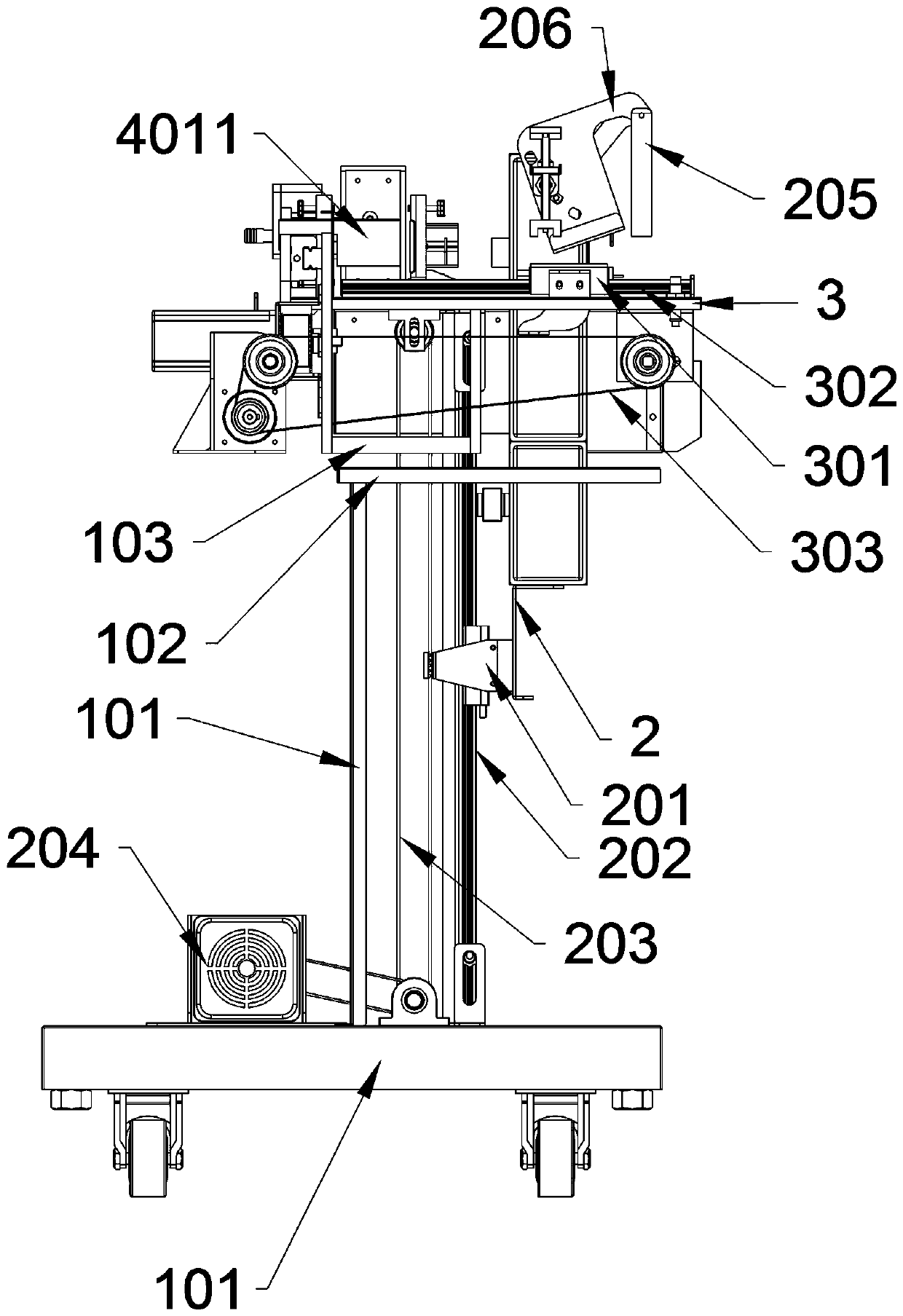

[0033] The specific embodiment of the present invention sees Figure 1-9 :

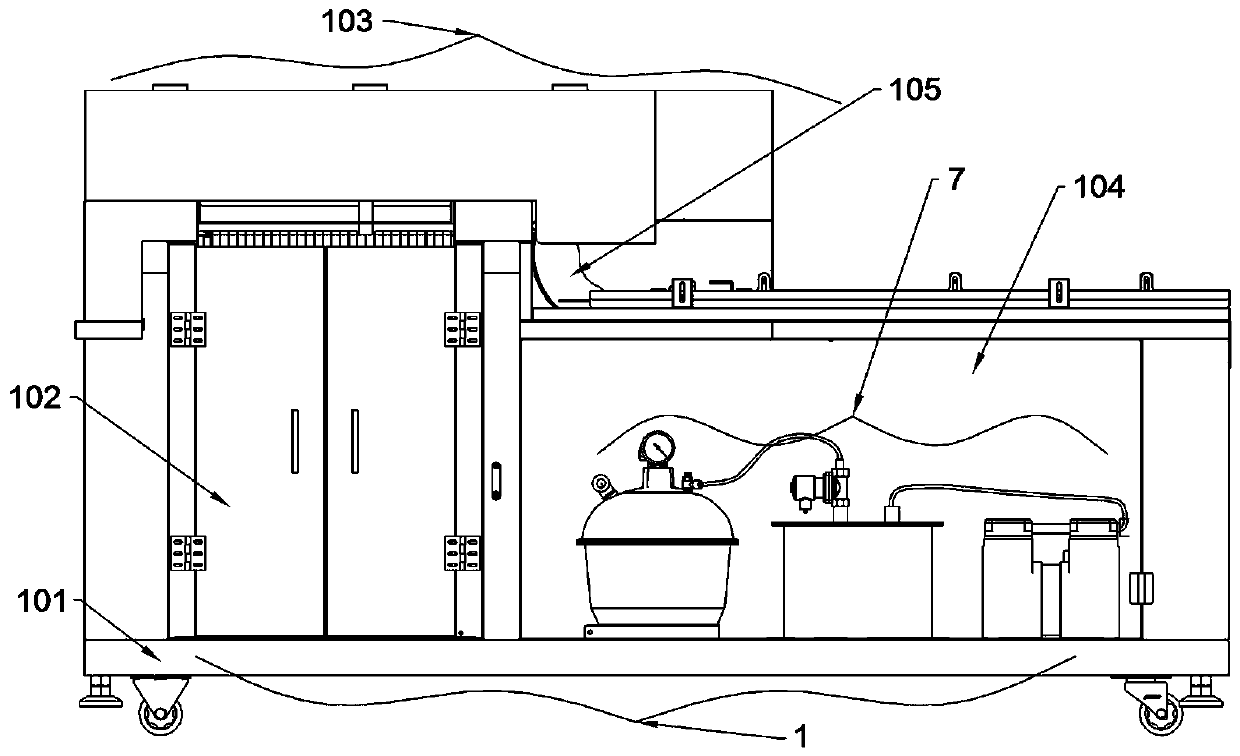

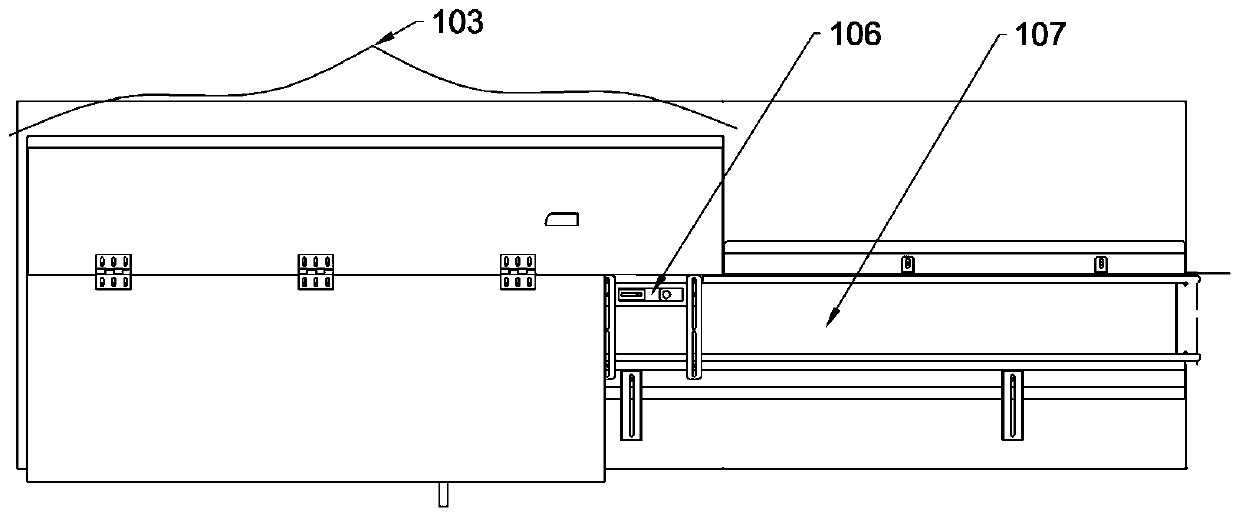

[0034] A kind of ampoule bottle holder fast feeding conveying device, such as figure 1 and 2 , including a box holder material preparation platform 1, the box holder material preparation platform 1 is provided with a material preparation cabinet 102 and a vacuum generation cabinet 104, a dustproof cover 103 is provided above the material preparation cabinet 102, a box holder material preparation mechanism is arranged in the material preparation cabinet 102, and a vacuum generation cabinet 104 is provided with a vacuum generating system 7, and the right side of the box holder material preparation mechanism is provided with a box holder pressing mechanism and a vacuum adsorption mechanism successively, and an arc-shaped glide path 105 is provided below the vacuum adsorption mechanism.

[0035] Such as Figure 3-5, the box holder material preparation mechanism includes a box holder push-up mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com