A kind of polycarboxylic acid organic ligand and synthetic method based on ndhpi modification

A technology of organic ligands and polycarboxylic acids, applied in the field of polycarboxylic acid organic ligands, can solve the problems of low catalytic activity, unfavorable reusability of MOFs materials, high reaction temperature, etc., and achieve wide application prospects, excellent catalytic efficiency and Recyclability and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

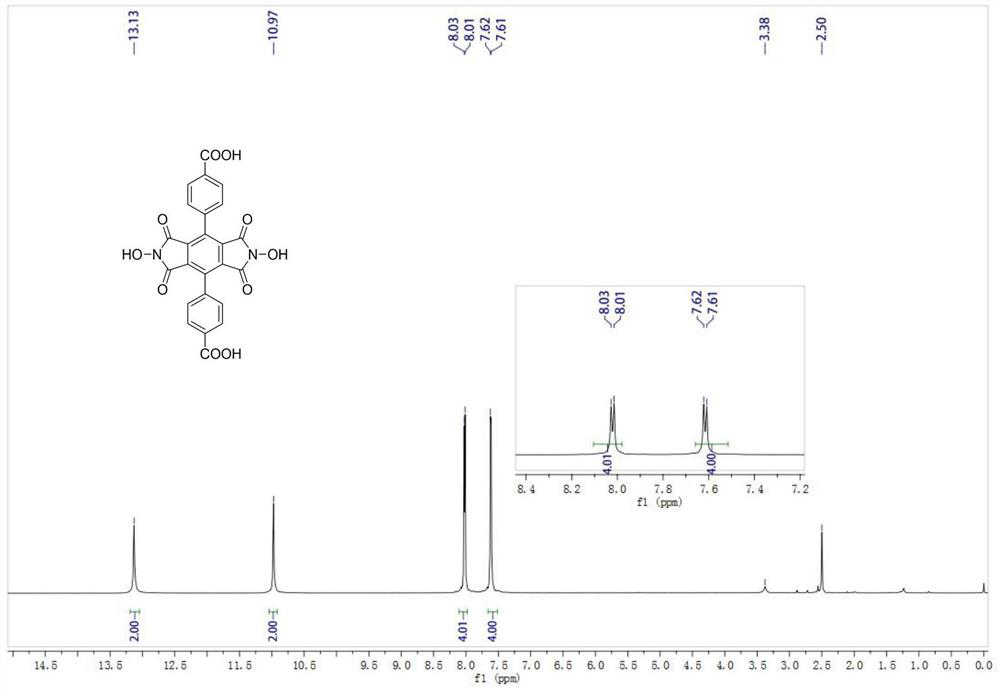

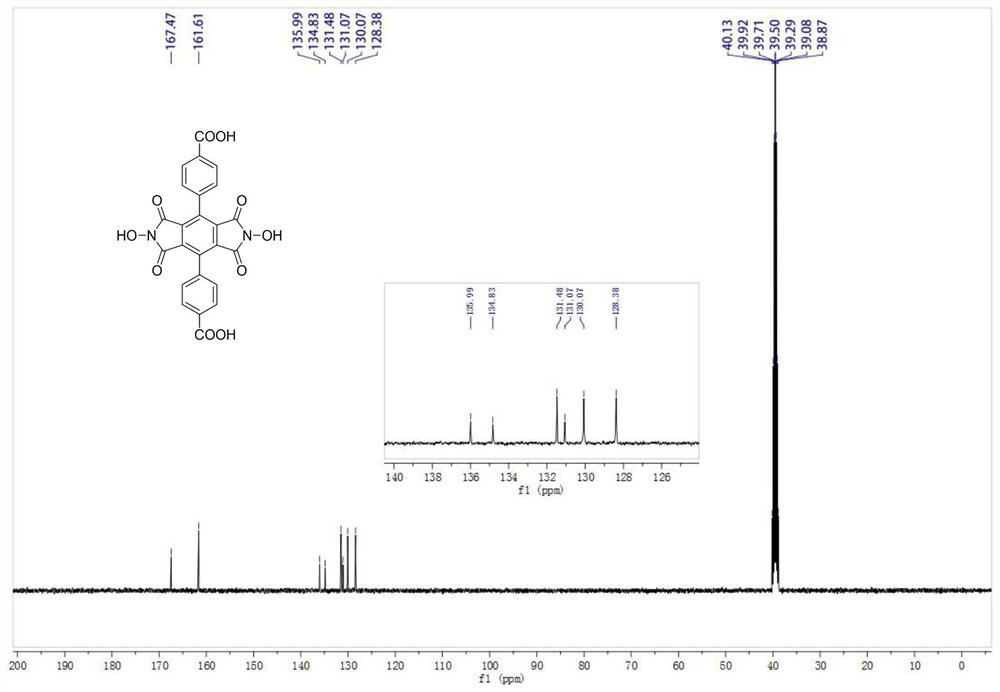

[0034] Polycarboxylic acid organic ligand (a) based on N,N′-dihydroxypyromellitic imide (NDHPI): 4,4’-(2,6-dihydroxy-1,3,5,7- Tetraoxo 1,2,3,5,6,7-hexahydropyrrolo[3,4-F]isoindole-4,8-diyl)dibenzoic acid (referred to as H 2 L 2N-OH ) The specific structure is as follows:

[0035]

[0036] h 2 L 2N-OH The reaction formula of the synthetic method is as follows:

[0037]

[0038] Preparation of polycarboxylic acid organic ligand (a) based on N,N′-dihydroxypyromellitic acid imide (NDHPI): in N 2 Add 6.5mmol3,6-dibromotetramethylbenzene, 13mmol4-methylphenylboronic acid, 26mmol sodium carbonate, 0.2mmol tetrakistriphenylphosphopalladium, 30ml1,4-dioxane, 5.9ml Deionized water was replaced with nitrogen three times, and then heated to 100° C. in an oil bath under magnetic stirring, and reacted for 8 hours. After the reaction was completed, it was allowed to stand at room temperature, and then the solid powder precipitated from the reaction solution was suction-filtered a...

Embodiment 2

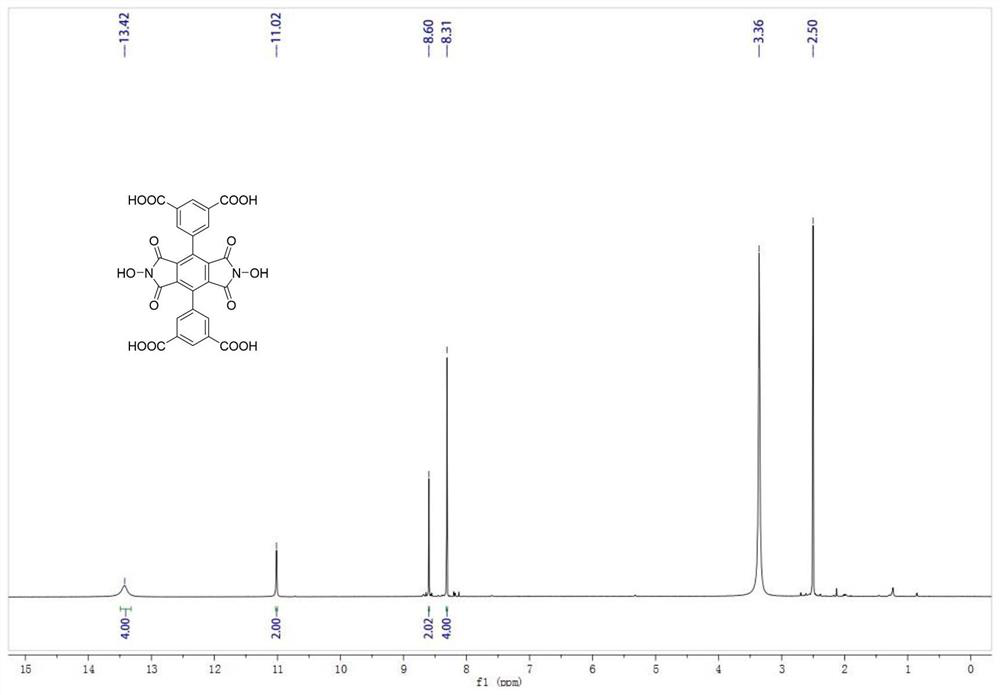

[0044] N,N′-dihydroxypyromellitic acid imide modified polycarboxylic acid organic ligand (b): 5,5’-(2,6-dihydroxy-1,3,5,7-tetraoxo 1 ,2,3,5,6,7-hexahydropyrrolo[3,4-F]isoindole-4,8-diyl)diisophthalic acid (referred to as H 4 L 2N-OH ) The specific structure is as follows:

[0045]

[0046] h 4 L 2N-OH The reaction formula of the synthetic method is as follows:

[0047]

[0048] Preparation of polycarboxylic acid organic ligand (b) based on N,N′-dihydroxypyromellitic acid imide modification: in N 2 Add 6.5mmol 3,6-dibromotetramethylbenzene, 13mmol 3,5-dimethylphenylboronic acid, 26mmol sodium carbonate, 0.2mmol tetrakistriphenylphosphopalladium, 30ml 1,4-dioxane to a 100ml three-necked flask under protection , 5.9ml of deionized water, and then replaced with nitrogen three times, and then heated to 120°C with an oil bath under magnetic stirring, and reacted for 12h. After the reaction was completed, it was allowed to stand at room temperature, and then the solid pow...

Embodiment 3

[0054] Weigh the ligand (a), ZrCl according to the molar ratio of 1:1.2:30 4 , Benzoic acid in a glass bottle, then add N,N'-dimethylformamide (DMF) solution and a drop of deionized water, ultrasonic for 10 minutes to clarify the solution, and then place the solution in a constant temperature oven at 70°C for reaction 2 days, then raise the temperature to 85°C for one day, and finally raise the temperature to 100°C to react for 2 days. After the reaction stops, the white powder precipitate obtained is washed with DMF and then soaked in acetone for 3 days. It is activated under vacuum at 120°C for 12 hours. Calculated based on the ligand The crystal yield is about 76%. PXRD test results show that the obtained white powder has good crystallinity, SEM scanning results show that the obtained white powder is a nano-scale regular octahedral structure with uniform size, and BET test results show that the specific surface area of the obtained material is 1470.2046m 2 .g -1 , thus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com