Aluminum tape

An aluminum foil tape, aluminum foil technology, applied in the direction of adhesive, film/sheet adhesive, coating, etc., can solve the problems of increasing material cost, increasing use cost, unable to realize self-winding, etc., to save production cost, Good bonding, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

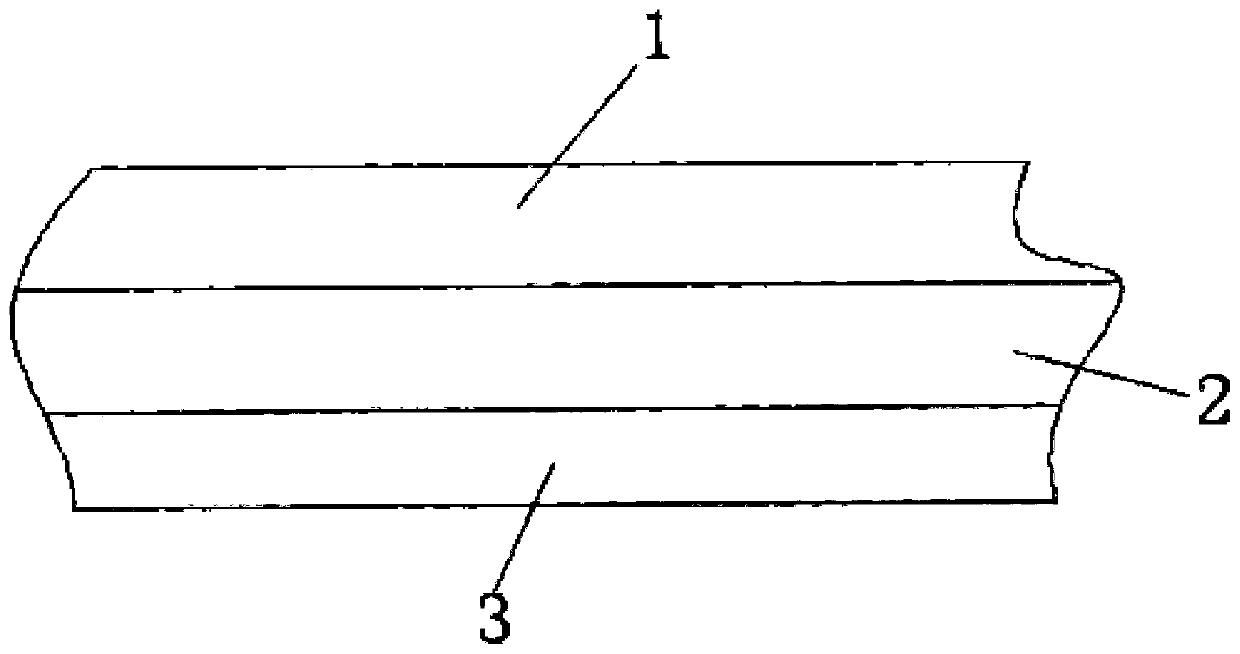

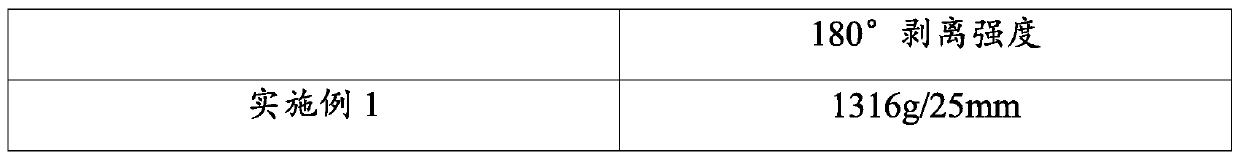

[0019] Take an aluminum foil with a thickness of 50 μm as the aluminum foil base material layer 2, and evenly coat a layer of acrylic adhesive with a thickness of 30 μm on one side of the aluminum foil base material layer 2 to form an adhesive layer 3, which is evenly coated on the other side of the aluminum foil base material layer 2. A release agent with a thickness of 20 μm is coated to form a release layer 1, and an aluminum foil tape can be obtained after drying. The weight percentages of the components of the release layer 1 are: 30% of silicone oil, 56.7% of solvent, 8% of auxiliary agent, 5% of resin, and 0.3% of crosslinking agent. The silicone oil includes liquid silicone oil with a methylphenyl group and a high-hydrogen silicone oil, which can significantly improve the bonding force with polyurethane foam; the solvent is toluene; the auxiliary agent is ammonia ; The resin includes methyl MQ resin and phenolic resin; the crosslinking agent is dibenzoyl peroxide.

Embodiment 2

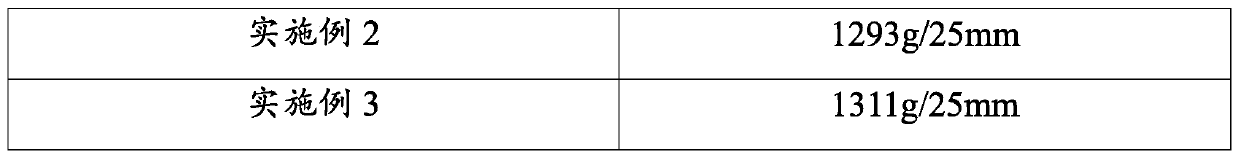

[0021] Take an aluminum foil with a thickness of 50 μm as the aluminum foil base material layer 2, and evenly coat a layer of acrylic adhesive with a thickness of 30 μm on one side of the aluminum foil base material layer 2 to form an adhesive layer 3, which is evenly coated on the other side of the aluminum foil base material layer 2. A release agent with a thickness of 20 μm is coated to form a release layer 1, and an aluminum foil tape can be obtained after drying. The weight percentage of each component of the release layer 1 is: 40% of silicone oil, 51.8% of solvent, 5% of auxiliary agent, 3% of resin, and 0.2% of crosslinking agent. The silicone oil includes liquid silicone oil with a methylphenyl group and a high-hydrogen silicone oil, which can significantly improve the bonding force with polyurethane foam; the solvent is toluene; the auxiliary agent is ammonia ; The resin includes methyl MQ resin and phenolic resin; the crosslinking agent is dibenzoyl peroxide.

Embodiment 3

[0023] Take an aluminum foil with a thickness of 50 μm as the aluminum foil base material layer 2, and evenly coat a layer of acrylic adhesive with a thickness of 30 μm on one side of the aluminum foil base material layer 2 to form an adhesive layer 3, which is evenly coated on the other side of the aluminum foil base material layer 2. A release agent with a thickness of 20 μm is coated to form a release layer 1, and an aluminum foil tape can be obtained after drying. The weight percentages of the components of the release layer 1 are: 50% of silicone oil, 44.9% of solvent, 3% of auxiliary agent, 2% of resin, and 0.1% of crosslinking agent. The silicone oil includes liquid silicone oil and high hydrogen-containing silicone oil with a methyl phenyl group, and the high hydrogen-containing silicone oil can significantly improve the bonding force with the polyurethane foam layer; the solvent is toluene; the auxiliary agent is Ammonia; the resin includes methyl MQ resin and phenoli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com