Conductive pressure-sensitive adhesive for splicing stainless steel and aluminum alloy as well as preparation and using methods thereof

A technology of stainless steel and aluminum alloy, applied in the direction of surface pretreatment bonding method, adhesive type, conductive adhesive, etc., can solve poor electrical conductivity, cannot meet the requirements of electrical conductivity and bonding at the same time, bonding Poor performance and other problems, to achieve the effect of good bonding, long-lasting bonding time, and not easy to accelerate galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

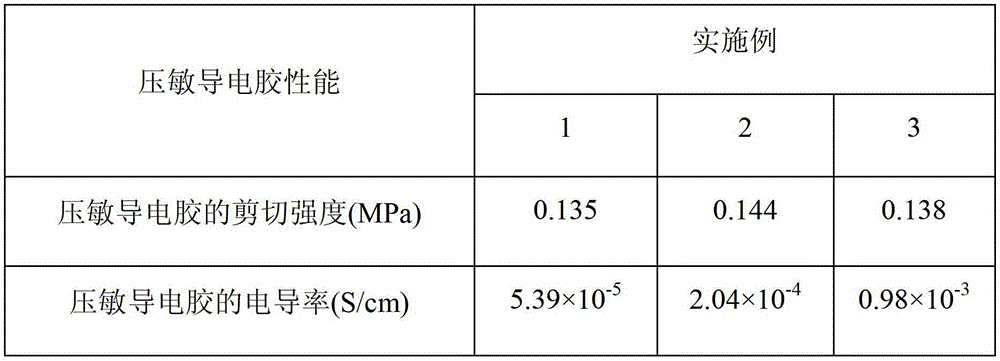

Embodiment 1

[0027] The component of embodiment 1 is:

[0028] 40% polyacrylate, 10% conductive material and 0.6% KH570, the rest is butanone solvent;

Embodiment 2

[0029] The component of embodiment 2 is:

[0030] 40% polyacrylate, 15% conductive material and 0.6% KH570, the rest is butanone solvent;

Embodiment 3

[0031] The component of embodiment 3 is:

[0032] 40% polyacrylate, 20% conductive material and 0.6% KH570, the rest is butanone solvent;

[0033] 3. The method of using conductive pressure-sensitive adhesive to bond stainless steel and aluminum alloy:

[0034] Prepare primer:

[0035] Mix 72% methanol, 20% KH570 and 8% water to obtain primer;

[0036] Pretreatment of stainless steel and aluminum alloy materials: clean the burrs on the surface of stainless steel and aluminum alloy products, polish off the oxide layer, and then clean the surface impurities with acetone and water;

[0037] Apply the primer to the area where the stainless steel or aluminum alloy products are to be bonded, so that the surface of the product is evenly wetted, and let it dry for 10 minutes. Then apply the conductive pressure-sensitive adhesive to the surfaces of the two products, and apply force after 5 minutes to bond the two surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com