Preparation method of novel composite solid gum

A solid glue, a new type of technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of heat resistance, application limitations, etc., and achieve the effect of increasing thermal performance, strong reactivity, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

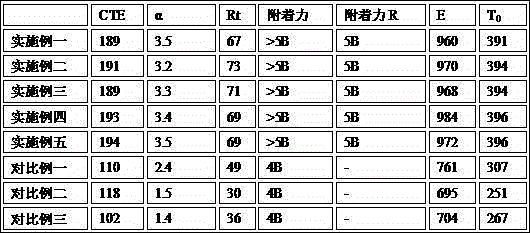

Examples

Embodiment

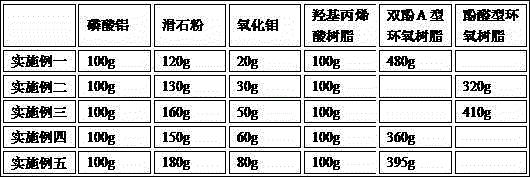

[0018] According to the ratio in Table 1, react hydroxy acrylic resin and epoxy resin at 120°C for 30 minutes to obtain epoxy resin prepolymer; grind aluminum phosphate and mix it with talcum powder as filler.

[0019] Table 1 raw material quality

[0020]

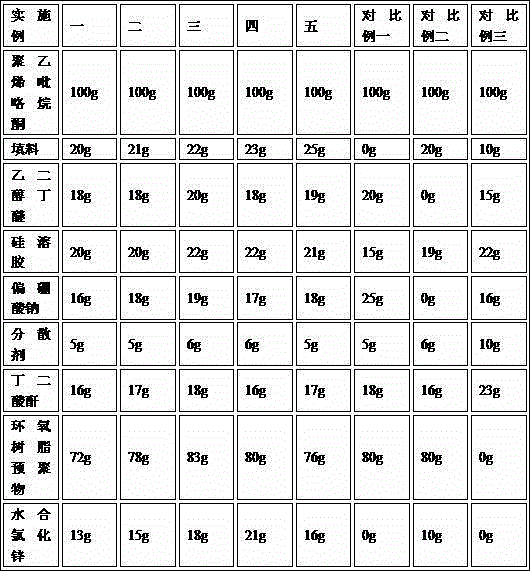

[0021] According to the ratio in Table 2, mix the filler, ethylene glycol butyl ether, and silica sol (solid content is 45%; the particle size of silica is 150-430 nanometers) for 1 hour to obtain a mixture; sequentially mix sodium metaborate, sulfuric acid Add ester dispersant and succinic anhydride to the mixture, stir for 0.5 hours, then add epoxy resin prepolymer, stir at 140°C for 3 hours; finally add polyvinylpyrrolidone, zinc chloride hydrate, stir at 60°C for 8 hours, Obtain the composite; then put the composite into a mold and press cold (0.3MPa; room temperature) to obtain a new type of composite solid glue.

[0022] Table 2 raw material quality

[0023]

[0024] Note: the epoxy resin prepolymer of compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com