Dredging antifouling system

An anti-fouling and control system technology, applied in water conservancy projects, water conservancy engineering equipment, buildings, etc., can solve the problems of hindering the navigation of ships, limited operability and practicability of anti-fouling curtains, etc., and achieve the effect of improving speed and anti-fouling. Significant, increase the effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

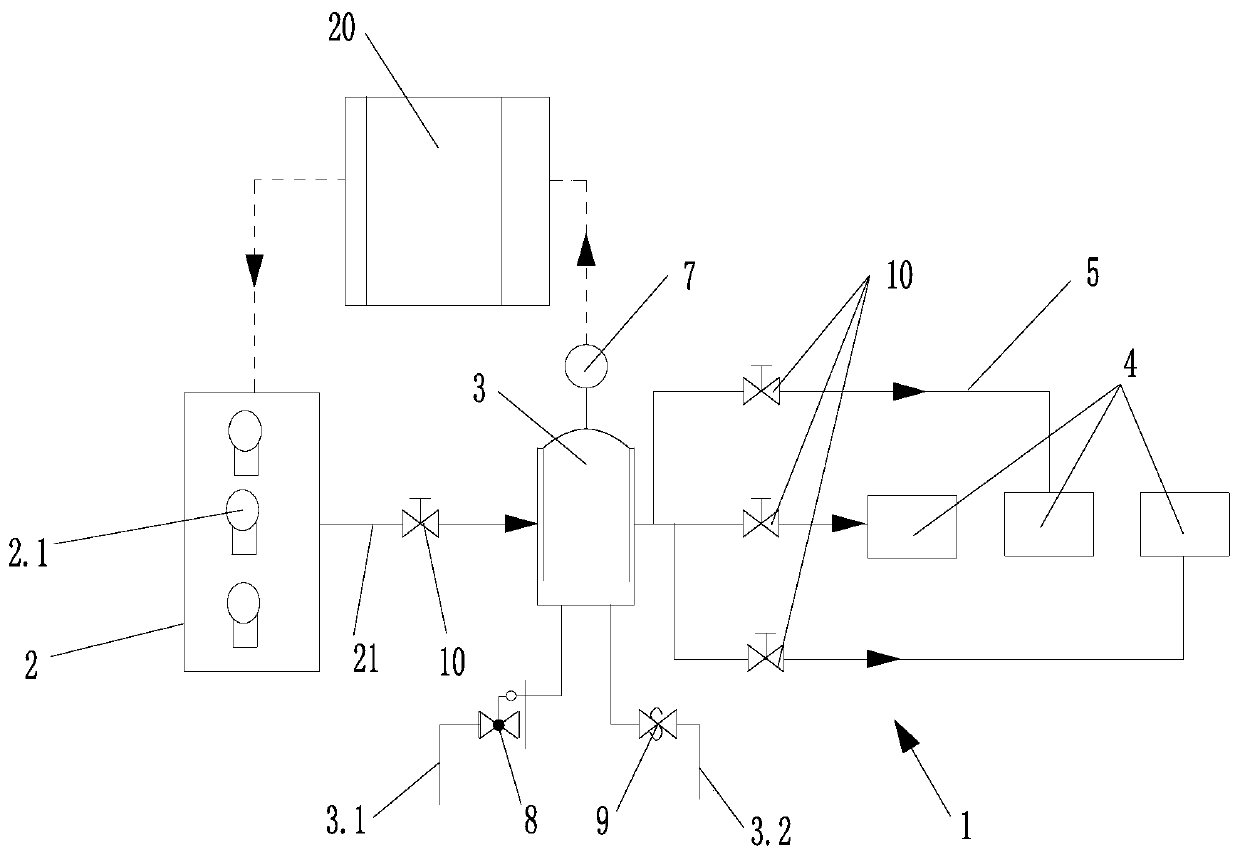

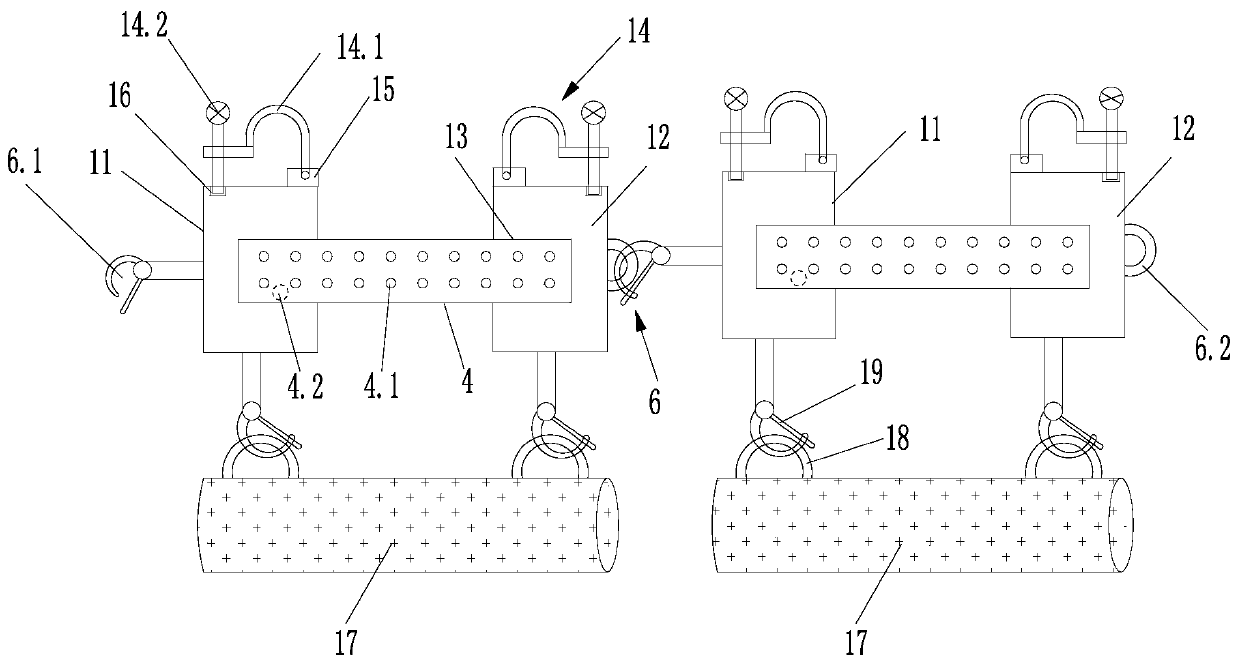

[0026] Such as figure 1 The dredging antifouling system shown in includes several air bubble antifouling units 1 and a control system 20, and each air bubble antifouling unit 1 includes an air compressor unit 2, a surge tank 3, and a plurality of perforated aeration pipes 4; The air outlet of the air compressor unit 2 is connected to the air inlet of the surge tank 3 through the air duct 21, and the air outlet of the surge tank 3 is respectively connected to the air inlets of the multiple perforated aeration pipes 4 through a plurality of flexible connecting pipes 5 The outer wall of the perforated aeration pipe 4 is provided with a number of aeration holes 4.1 arranged in rows; the flexible connecting pipe 5 and the air guide pipe 21 are provided with a regulating valve 10 for controlling the gas flow. The air compressor unit 2 includes severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com