An anti-shock device for ship's tank-piercing pipeline

A technology of impact resistance and piping, applied in the direction of pipes, pipe components, pipe supports, etc., can solve the problems of large, easy to break, and large pipe flexibility, and achieve the goal of ensuring life, preventing fracture, and improving fatigue life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0032] The directional terms mentioned in the present invention, such as "upper", "lower", "left", "right", "inner", "outer", "side", etc., are only referring to the directions of the drawings. Therefore, the use of directional terms is used to illustrate and understand the present invention, but not to limit the present invention.

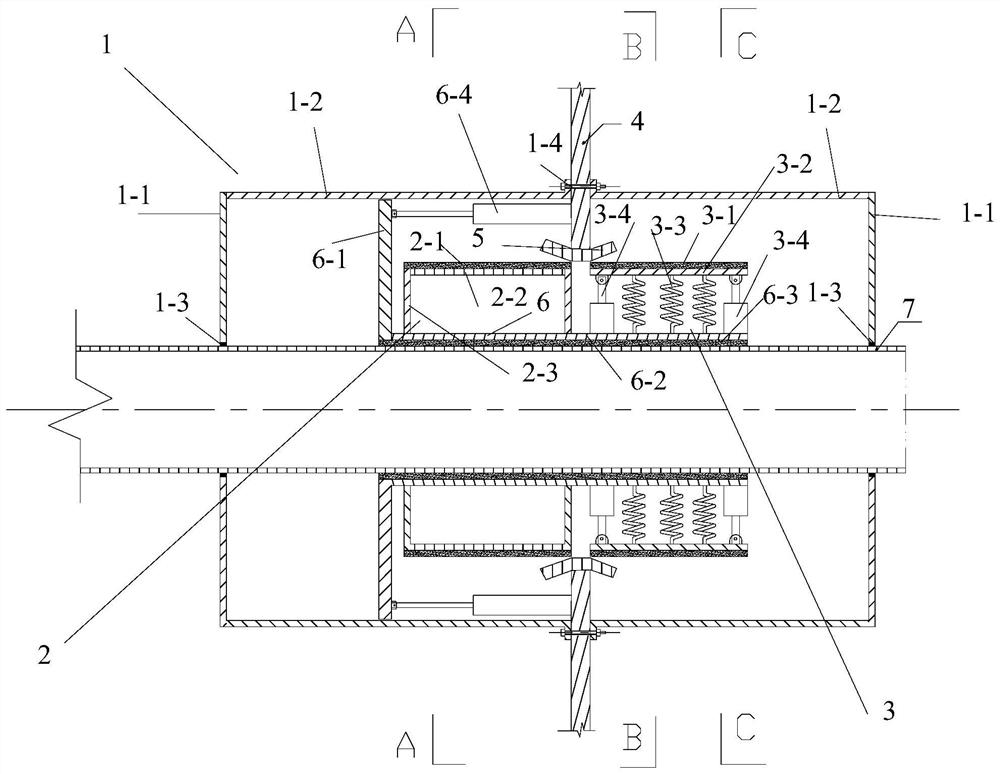

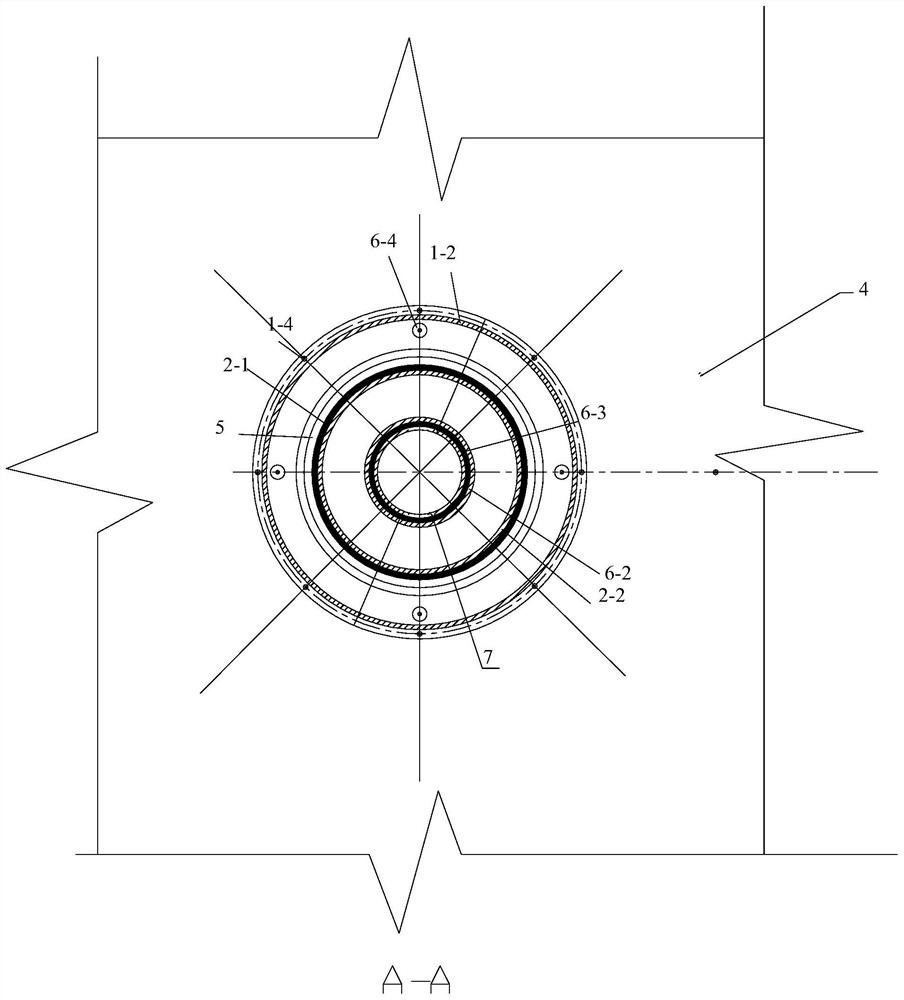

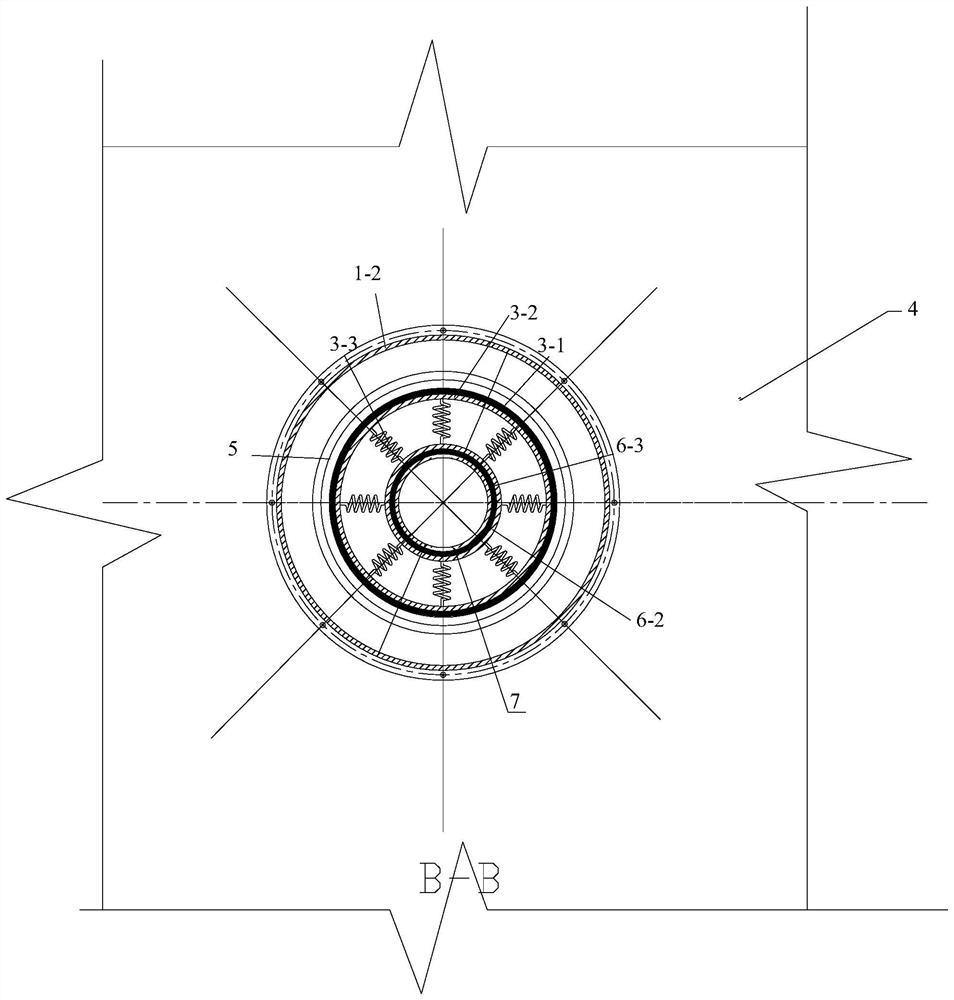

[0033] see Figure 1 to Figure 4 As shown, it is an anti-shock device for ship penetration pipelines of the present invention, which includes an outer cylinder body 1, a connecting pipe 6, a rigid connection device 2, an anti-shock device 3, and a bulkhead sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com