Large-caliber lubricating oil path online metal particle monitoring device and detection method

A technology of metal particles and lubricating oil circuit, which is applied in measuring devices, particle and sedimentation analysis, particle size analysis, etc., to achieve the effect of high safety, simple operation method and simple driving circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] On the basis of the above, this embodiment introduces a method for monitoring and detecting metal particles in a large-diameter lubricating oil line, which specifically includes the following steps:

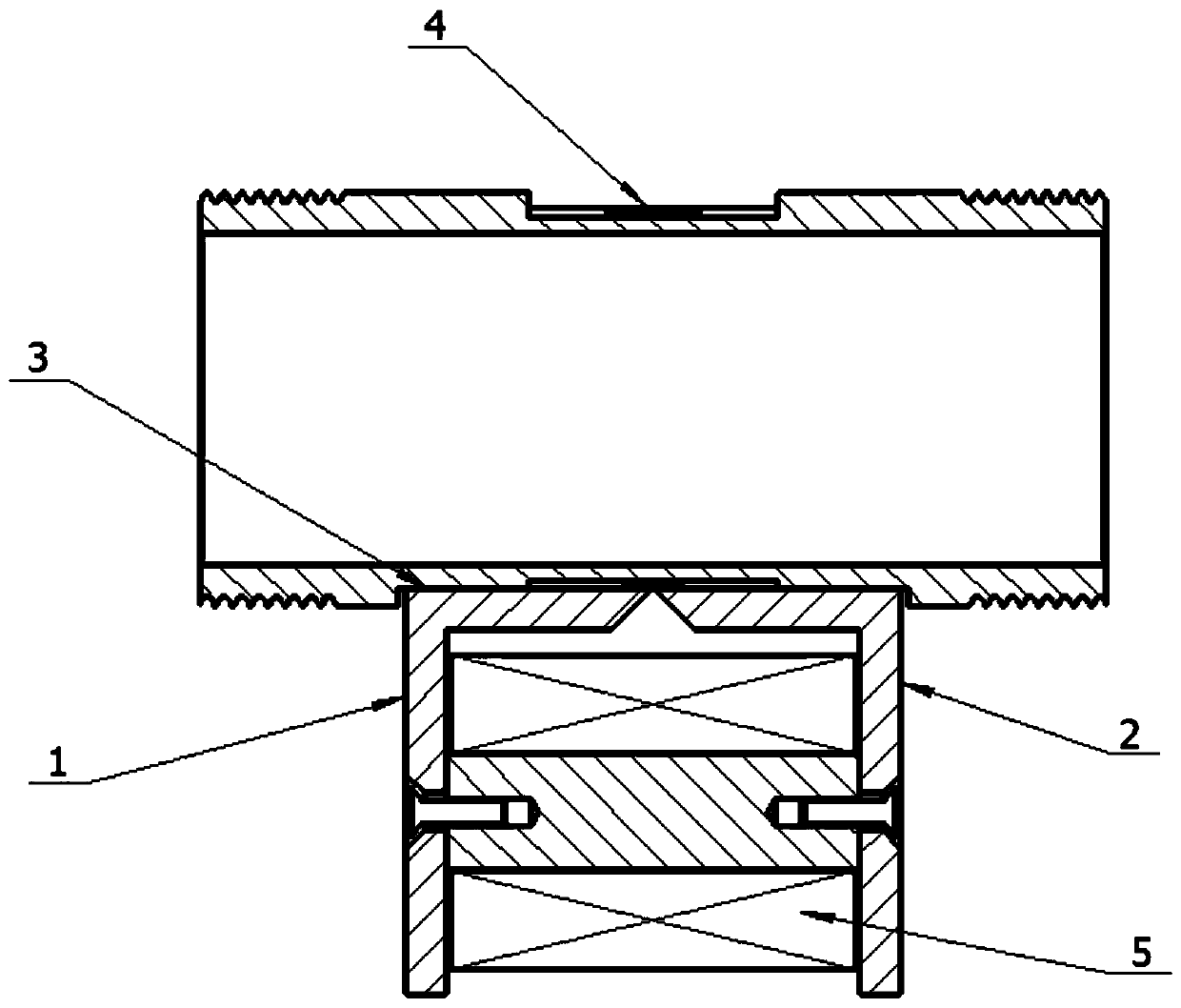

[0025] Guide the oil through a large-diameter oil pipe along the lubricating oil system of the mechanical equipment. The size of the large-diameter oil pipe used in this embodiment is 50mm in outer diameter×40mm in inner diameter×110mm in length, and the two magnetic poles of the sensor are attached to the outside of the large-diameter oil pipe. Together, the distance from the upper surface of the first magnetic pole and the second magnetic pole to the inner wall of the large-diameter oil pipe is 3mm;

[0026] Connect the excitation coil on the sensor to a DC power supply with a drive current of 0.6A, and use a DC signal to drive the excitation coil to generate a high-gradient static magnetic field along the axial direction of the large-diameter oil pipe between the first m...

Embodiment 2

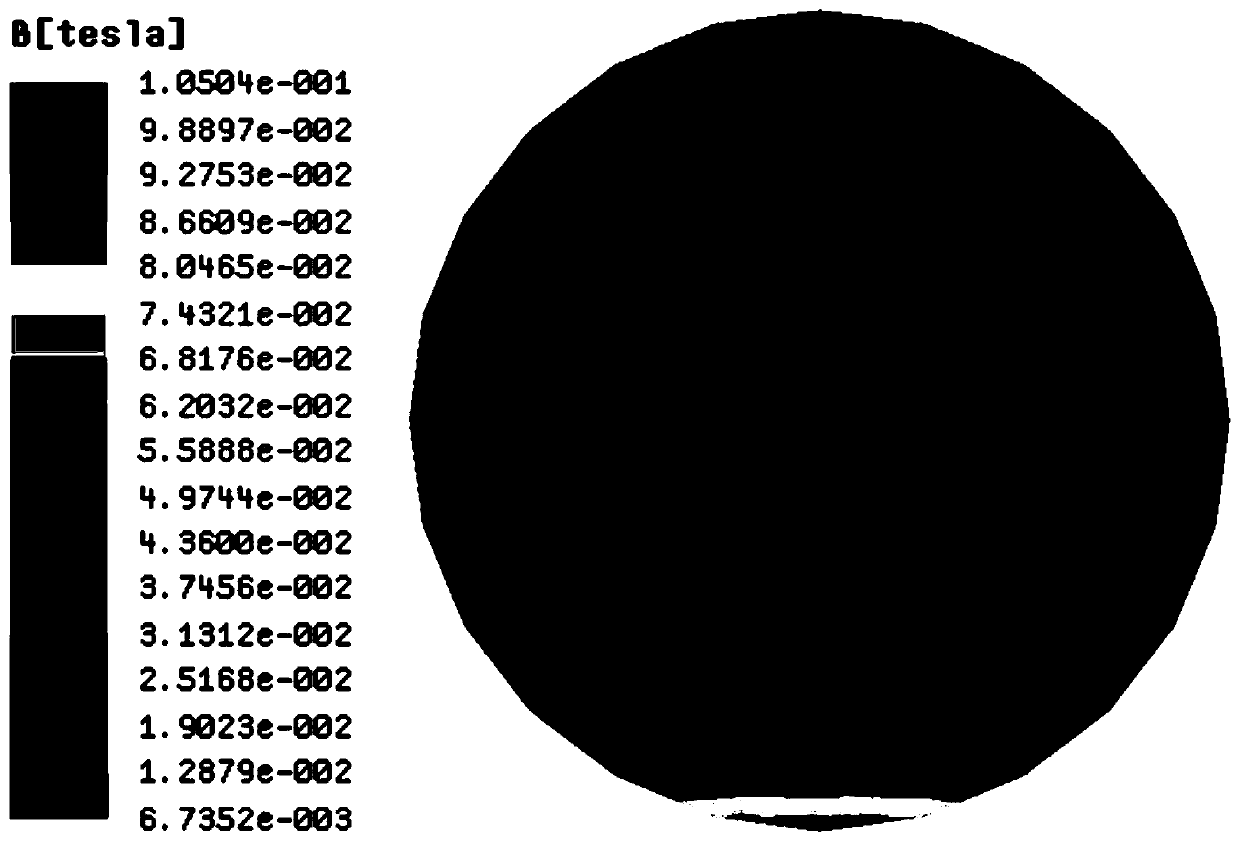

[0031] On the basis of this implementation 1, in order to illustrate the distribution of the magnetic field generated by the sensor and the induced voltage generated in the detection coil when the abrasive particles flow through the sensor, the finite element analysis of the sensor was carried out by using Ansoft Maxwell, and the magnetic field distribution in the oil pipe was obtained situation, such as figure 2 and image 3 shown by image 3 It can be seen that the distribution of the magnetic field in the longitudinal direction of the tubing is uneven, showing a high gradient change, and the magnetic induction intensity is the largest at the air gap of the two magnetic poles, and the farther away from the air gap, the weaker the magnetic induction. Only when the abrasive particles enter the local area near the air gap, the magnetic flux of the detection coil will change, which helps to improve the abrasive particle resolution.

[0032] Assuming that a 1mm×1mm×1mm copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com