Multi-beam combiner

A beam combiner, multi-beam technology, applied in optics, instruments, optical components, etc., can solve problems such as complex structure and difficult realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

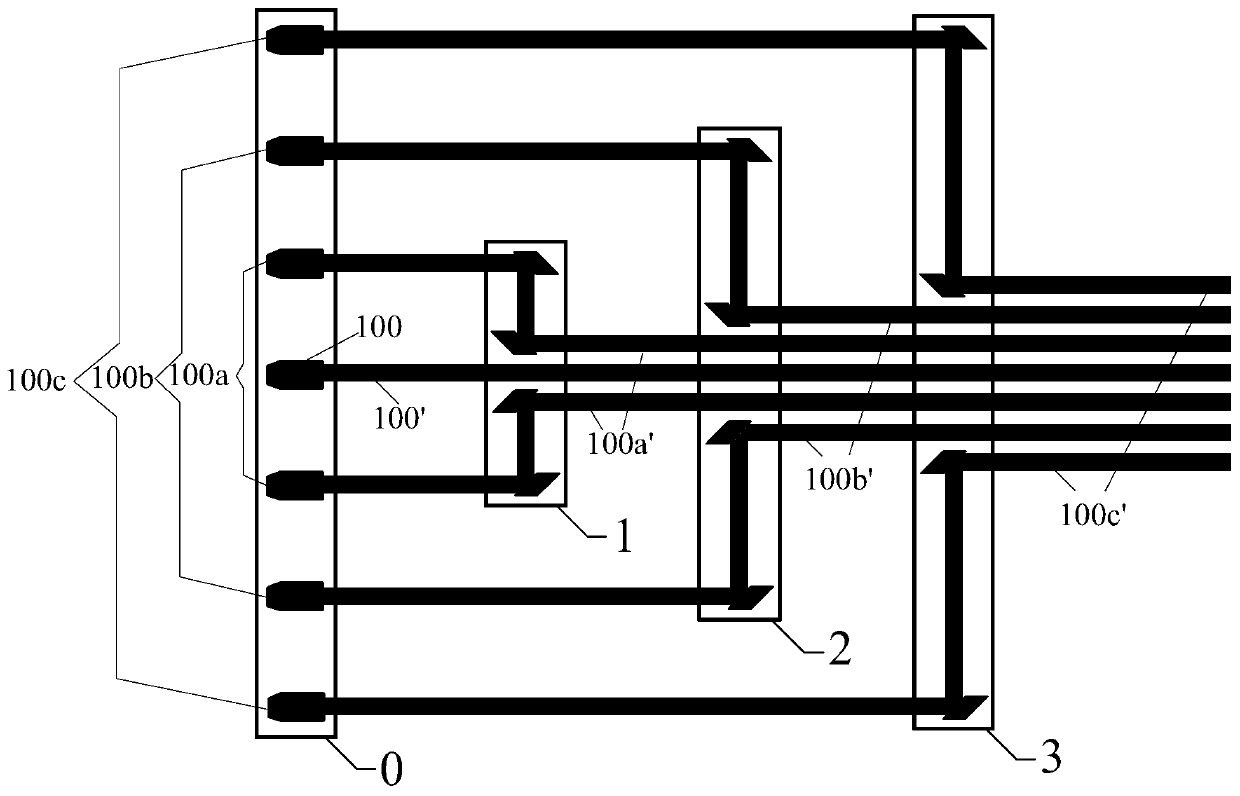

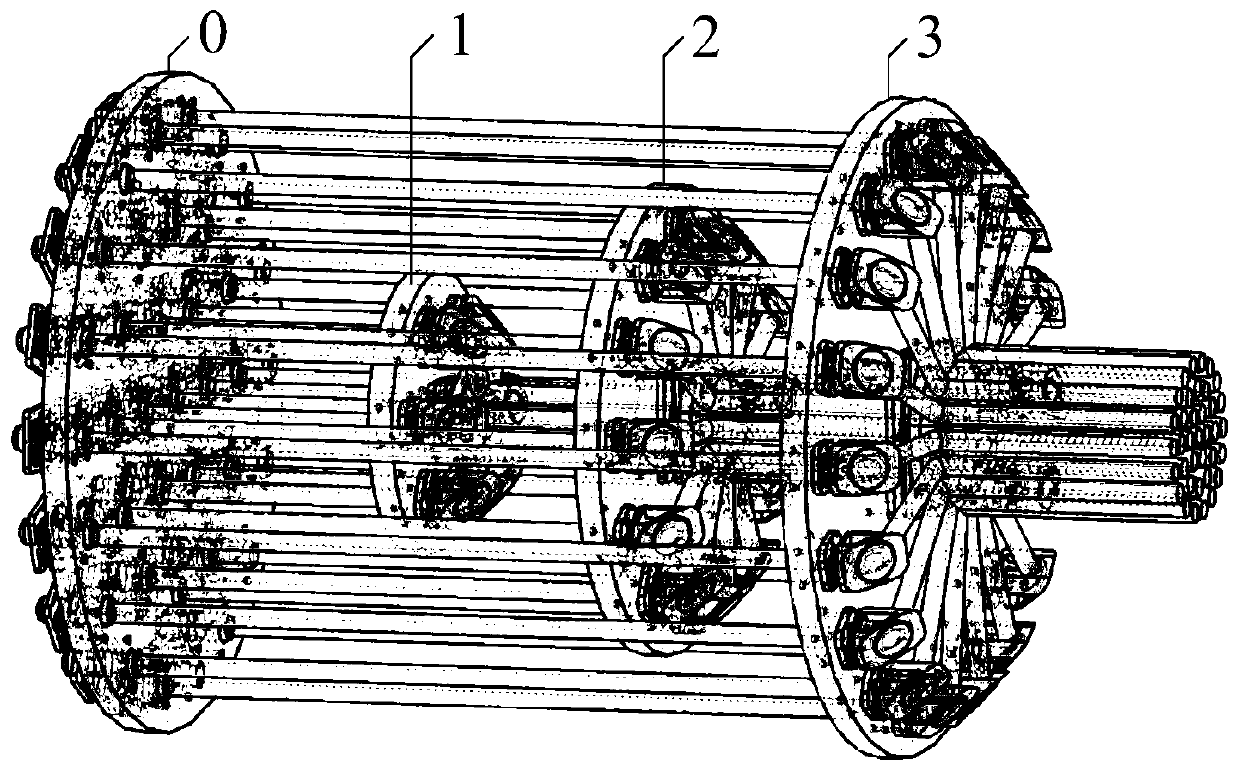

[0045] as attached figure 1 As shown, a multi-beam combiner at least includes: a beam collimator array 0 and N-stage beam combining devices, where N is an integer greater than 1. For example, it includes: a primary synthesis device 1 and a secondary synthesis device 2;

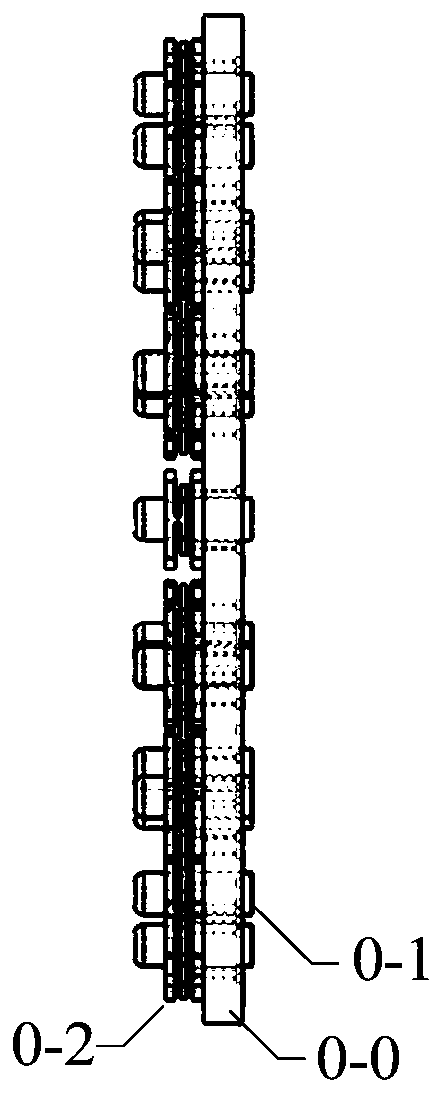

[0046] see image 3 , Figure 4, a beam collimator array 0, including several beam collimators 0-1, a collimator support plate 0-0 for providing installation support for the beam collimator 0-1, and a plurality of tilt adjustment frames 0-2 It is used to adjust the angle and position of the beam collimator 0-1, and it is arrayed layer by layer from the center to the edge, and the beam collimators of each layer are arranged in a closed shape on the collimator support plate 0-0; each layer Beam collimators are arranged on the collimator support plate 0-0 in a regular polygon or circle; in order to improve the concentration of the final beam concentration, the array shape of each layer of beam collimators is r...

Embodiment 1

[0070] see Figure 2-Figure 14 , the present embodiment discloses a reflective cascade multi-beam combiner. On the basis of the above-mentioned embodiments, the first-level combining unit, the second-level combining unit, and the third-level combining unit all include a number of 5 the same number) adjustable substrates, each of which includes:

[0071] The adjustable base 7 is installed on the side of the first support plate or the second support plate or the third support plate that is away from the collimator support plate 0-0, and is provided with output for the beam collimator the central hole through which the beam passes;

[0072] One end of the mirror mounting plate is hinged on the adjustable base 7, and the other end is mounted on the adjustable base 7 through an adjustable stud to adjust the inclination angle between the mirror mounting plate and the adjustable base 7 ; The external reflective mirror 5 is installed on the side of the mirror mounting plate close to...

Embodiment 2

[0088] This embodiment provides a transmissive cascaded multi-beam combiner, see Figure 15 , each level of beam combining device n includes: the nth beam combining support plate n-0, k n Prism-shaped beam transmitting body 8-n: in this embodiment, it is a three-stage cascade, n=3.

[0089] see Figure 16-21 , the central positions of the first-level support plate 1-0, the second-level support plate 2-0, and the third-level support plate 3-0 are all provided with a central hole, and the first-level prismatic beam transmission body 8-1 surrounds the first-level The central hole of the support plate 1-0 is radially arranged, the secondary prismatic beam transmitting body 8-2 is radially arranged around the central hole of the secondary support plate 2-0, and the third prism The beam-shaped beam transmitting body 8-3 is radially arranged around the central hole of the tertiary support plate 3-0;

[0090] The two ends of the prismatic light beam transmitting body have inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com