3d NAND memory and its formation method

A 3D NAND and memory technology, which is applied in the manufacture of semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve the problems of poor morphology of the side walls of the gate spacer, and achieve the effect of improving the performance of the common source of the array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

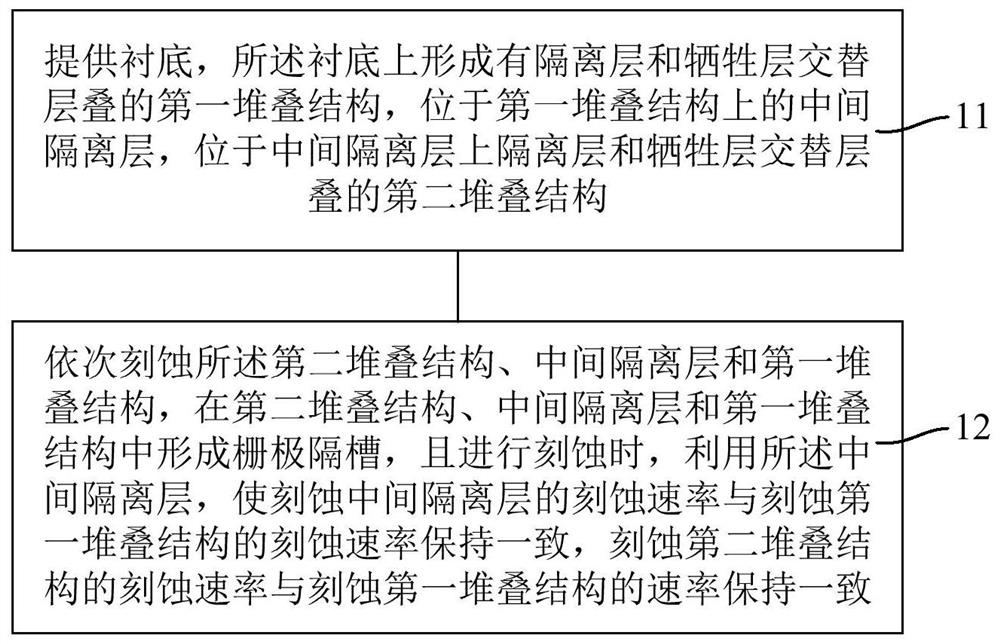

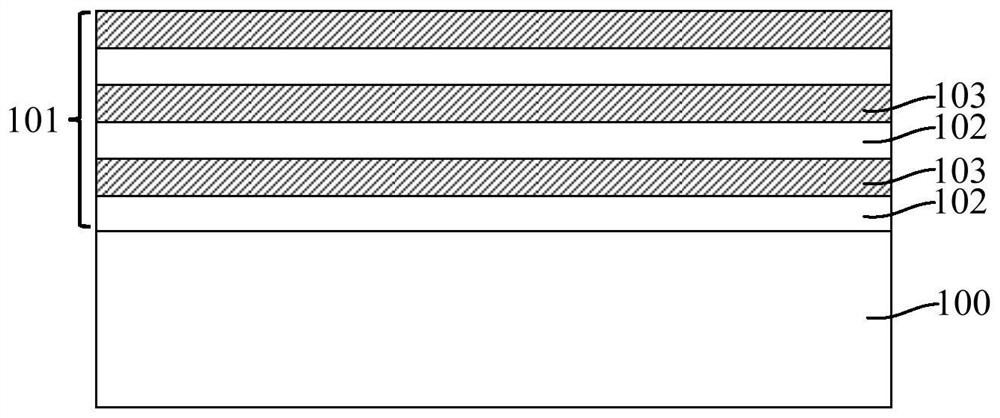

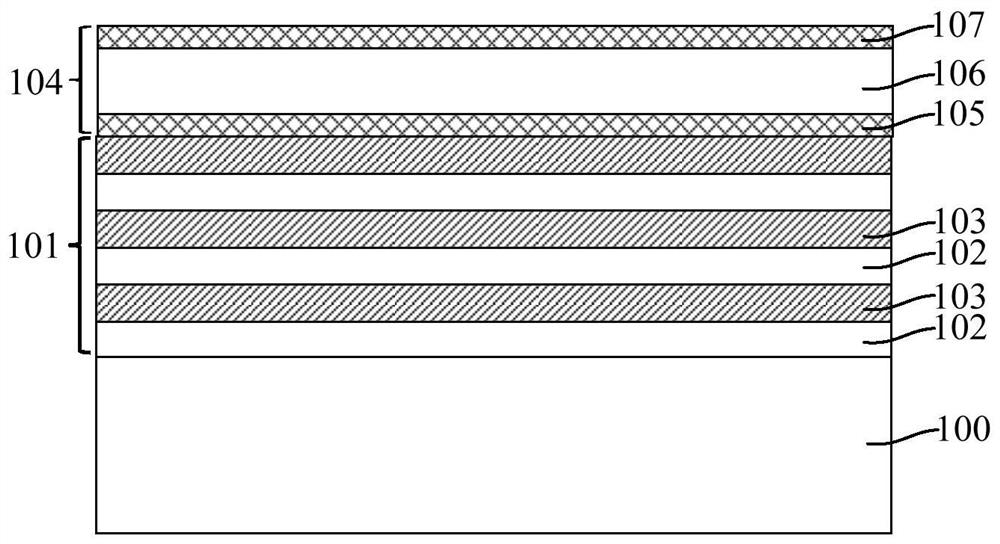

[0090] Figure 11-13 It is a schematic cross-sectional structure diagram of the formation process of the gate spacer of the 3D NAND memory according to another embodiment of the present invention. The difference between this embodiment and the foregoing embodiments lies in the specific structure of the isolation layer and the manner in which the etching rate for etching the intermediate isolation layer is consistent with the etching rate for etching the first stack structure and the second stack structure. It should be noted that, for descriptions or limitations of the same or similar structures in this embodiment as in the foregoing embodiments, please refer to the descriptions or limitations of corresponding parts in the foregoing embodiments, and details are not repeated in this embodiment.

[0091] In one embodiment, please refer to Figure 11 and Figure 12 , during etching, the method for keeping the etching rate of the intermediate isolation layer consistent with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com