Hub bearing flange plate multi-station precision forming technology and implement device thereof

A wheel bearing and precision forming technology, applied in forging/pressing/hammer devices, wheels, manufacturing tools, etc., can solve the problems of fast heat loss, low product precision, and more waste materials, so as to improve material utilization and increase size Accuracy, the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

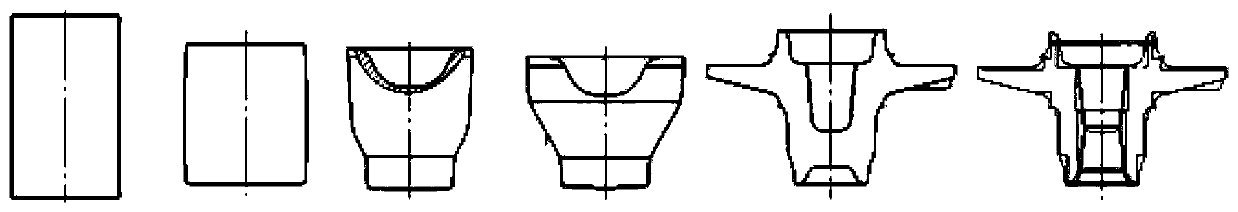

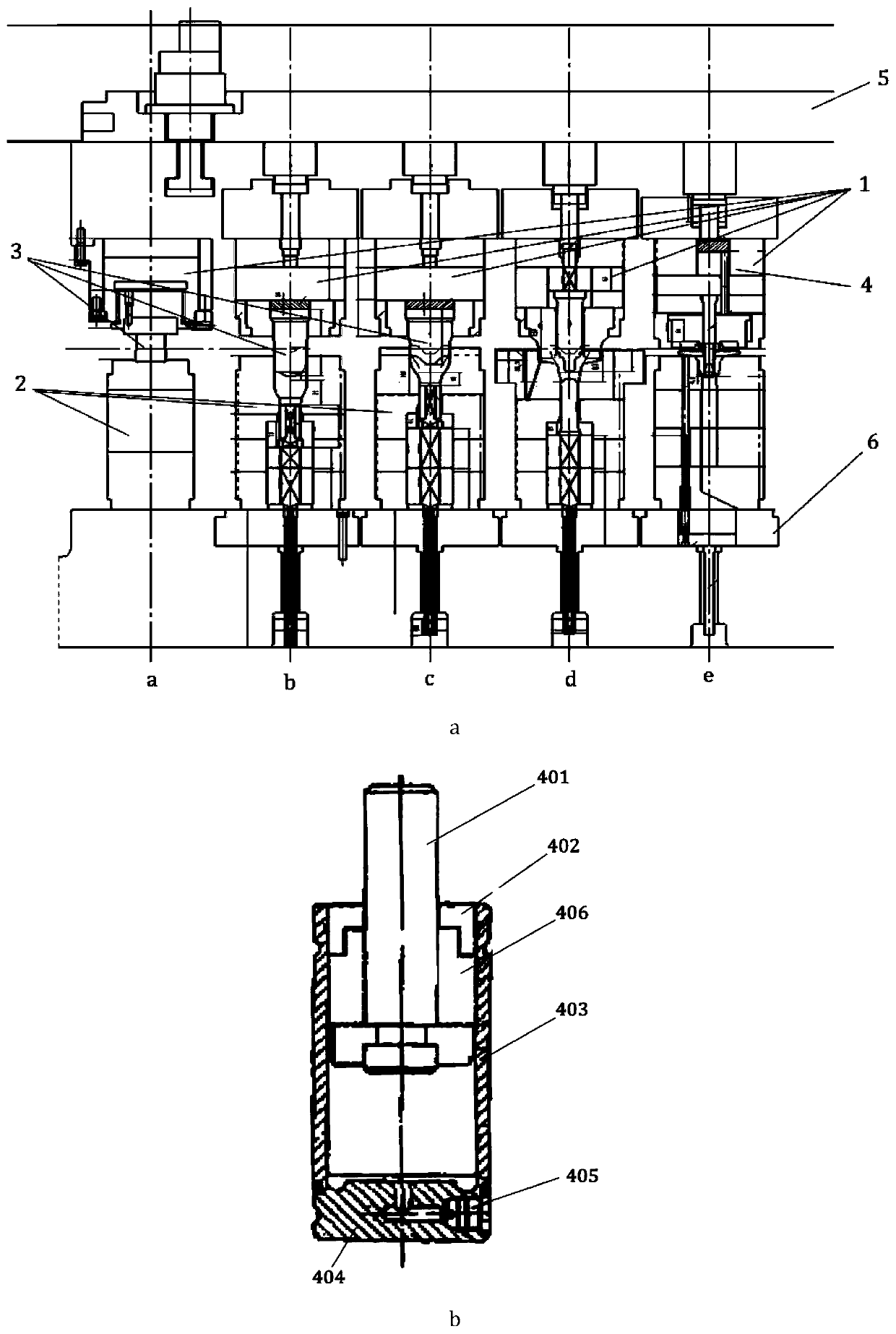

[0019] Such as figure 1 As shown, this embodiment includes five stations of upsetting unit a, forward extruding rod unit b, composite extrusion unit c, forming unit d, and punching unit e, which are processed independently in sequence, wherein:

[0020] The upsetting refers to: under the action of the upper and lower dies of the upsetting unit, the height of the product is deformed and reduced, and the final goal is to enlarge the diameter of the unit product to within 0.5 mm to 1 mm smaller than the diameter of the forward extrusion unit, and through upsetting The process realizes the effect of removing oxide skin on the surface of the product after heating.

[0021] The forward extruded rod part refers to: under the action of the upper die and the lower die of the forward extruded rod unit, the upset product is formed into a small diameter rod part through extrusion, so as to realize the material distribution of the product on the rod part.

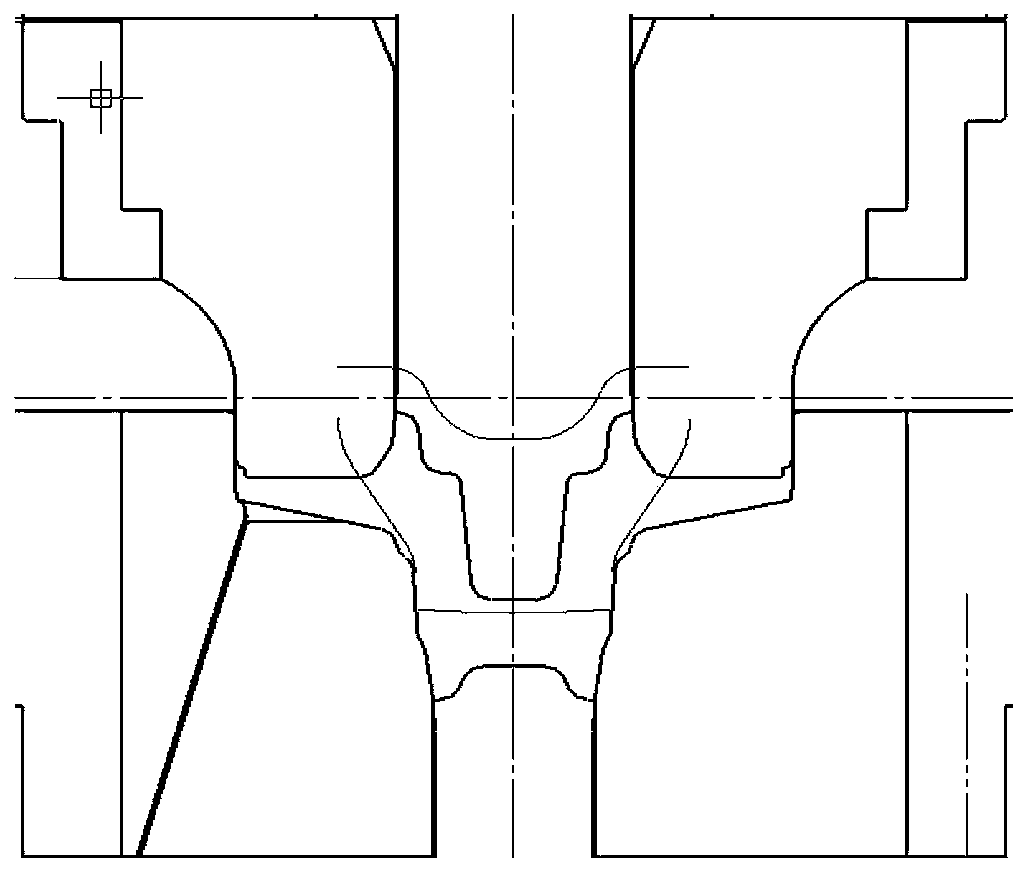

[0022] The composite extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com