Hybrid vehicle combined type energy management method

A hybrid vehicle and energy management technology, which is applied in the field of hybrid energy management of hybrid vehicles, can solve the problems of fast life decay, low maximum charging power, large brake system consumption, etc., so as to increase the balance compensation function and ensure SOC stability. , the effect of improving fuel saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

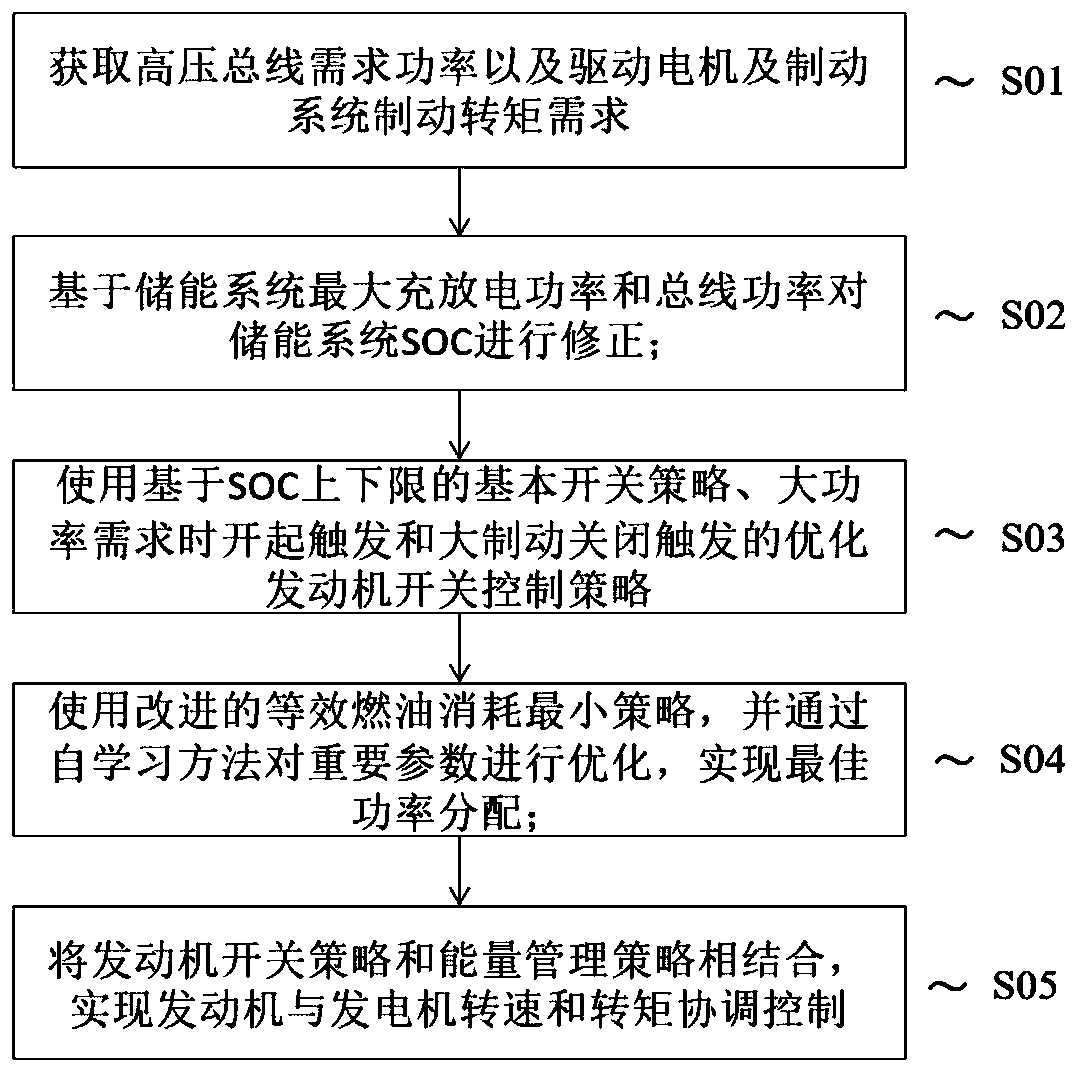

[0036] A hybrid energy management method for hybrid vehicles, the method includes the following steps:

[0037] S01: Obtain the high-voltage bus demand power and the braking torque demand of the drive motor and the brake system through signals such as the accelerator pedal, the brake pedal opening and the actual speed of the drive motor and the verified maximum charge and discharge power of the energy storage system;

[0038] The specific methods for obtaining the above-mentioned high-voltage bus demand power and the braking torque demand of the drive motor and braking system are as follows:

[0039] The signals such as accelerator pedal, brake pedal opening and actual speed of the drive motor and the maximum charge and discharge power of the power lithium battery pack are used as input parameters, which are divided into two working conditions of driving and braking conditions for calculation.

[0040] The calculation of the electric power demand of the driving working condition bus ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com