Raw material lifting device for livestock and poultry concentrated feed production

A technology of concentrated feed and raw materials, which is applied in the field of livestock and poultry concentrated feed lifting equipment, can solve the problems of inaccurate control of conveying rate, difficult to connect buckets, poor feed uniformity, etc., to achieve uniformity and accuracy, and ensure reliability , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

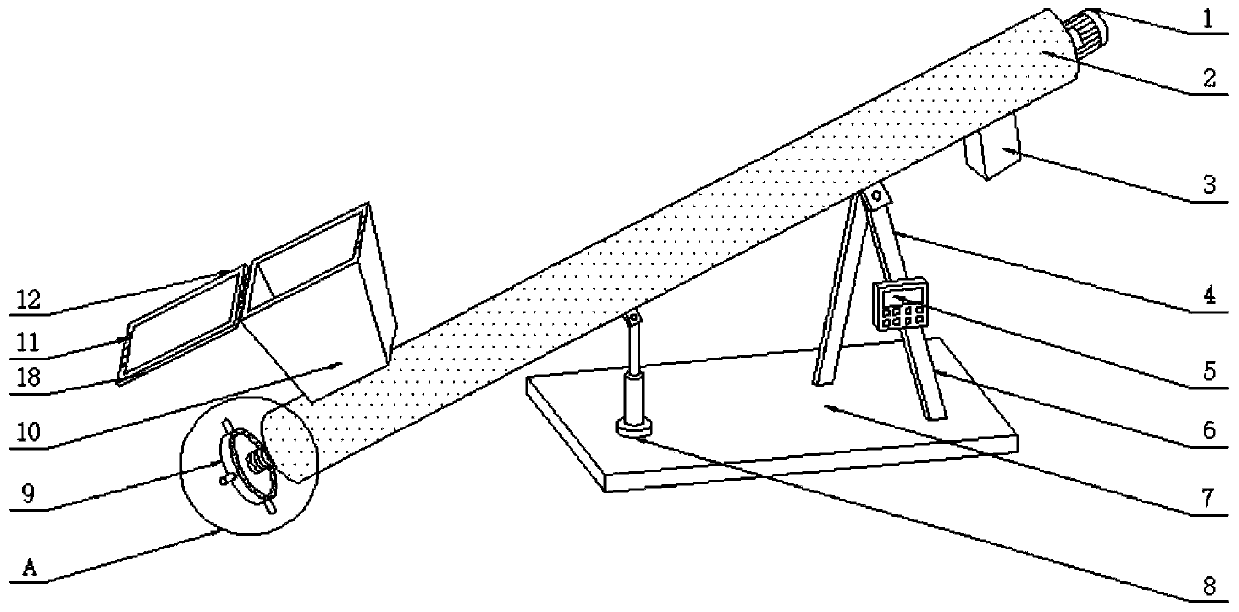

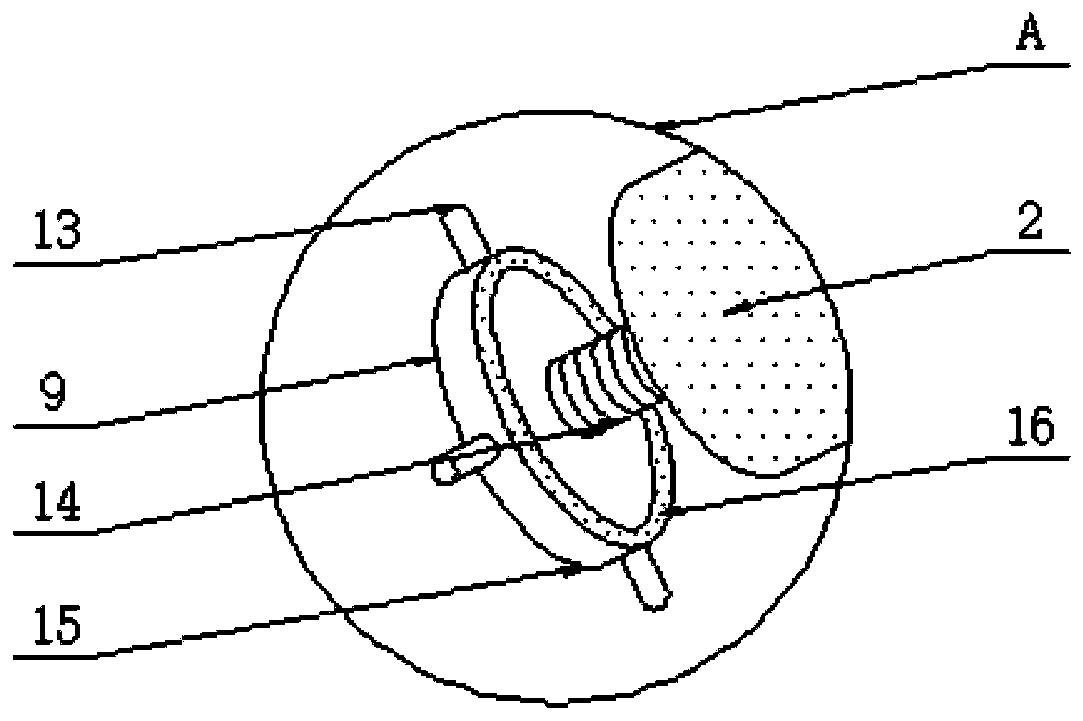

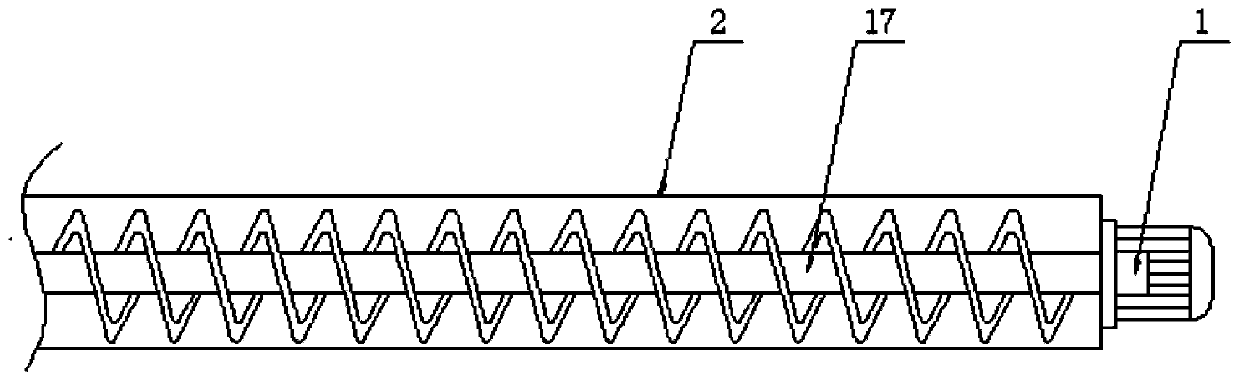

[0027] see Figure 1~5 , in an embodiment of the present invention, a raw material lifting device for the production of concentrated feed for livestock and poultry, including a hoist 2, an angle adjustment assembly 6, a sealing and noise reduction assembly, and a discharge control assembly, wherein the hoist 2 adopts the angle The adjustment assembly 6 can be installed on the panel 7 to adjust the inclination angle. The lower part of the hoist 2 is provided with a feed hopper 10 extending upwards. It is characterized in that the lower end of the hoist 2 near the feed hopper 10 is The sealing and noise reduction assembly is provided on the upper part of the elevator, the discharge control assembly is provided on the upper and lower sides of the elevator, the discharge control assembly communicates with the inner cavity of the elevator 2, and the discharge control assembly Components provide precise control over the rate of output.

[0028] In this example, if Figure 4-5 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com