Automatic underground conveying system

A technology of automatic transportation and belt transportation, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc. It can solve the problems of slow head-on progress, low excavation efficiency, and inconvenient operation of mining vehicles, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further explained below in conjunction with the accompanying drawings.

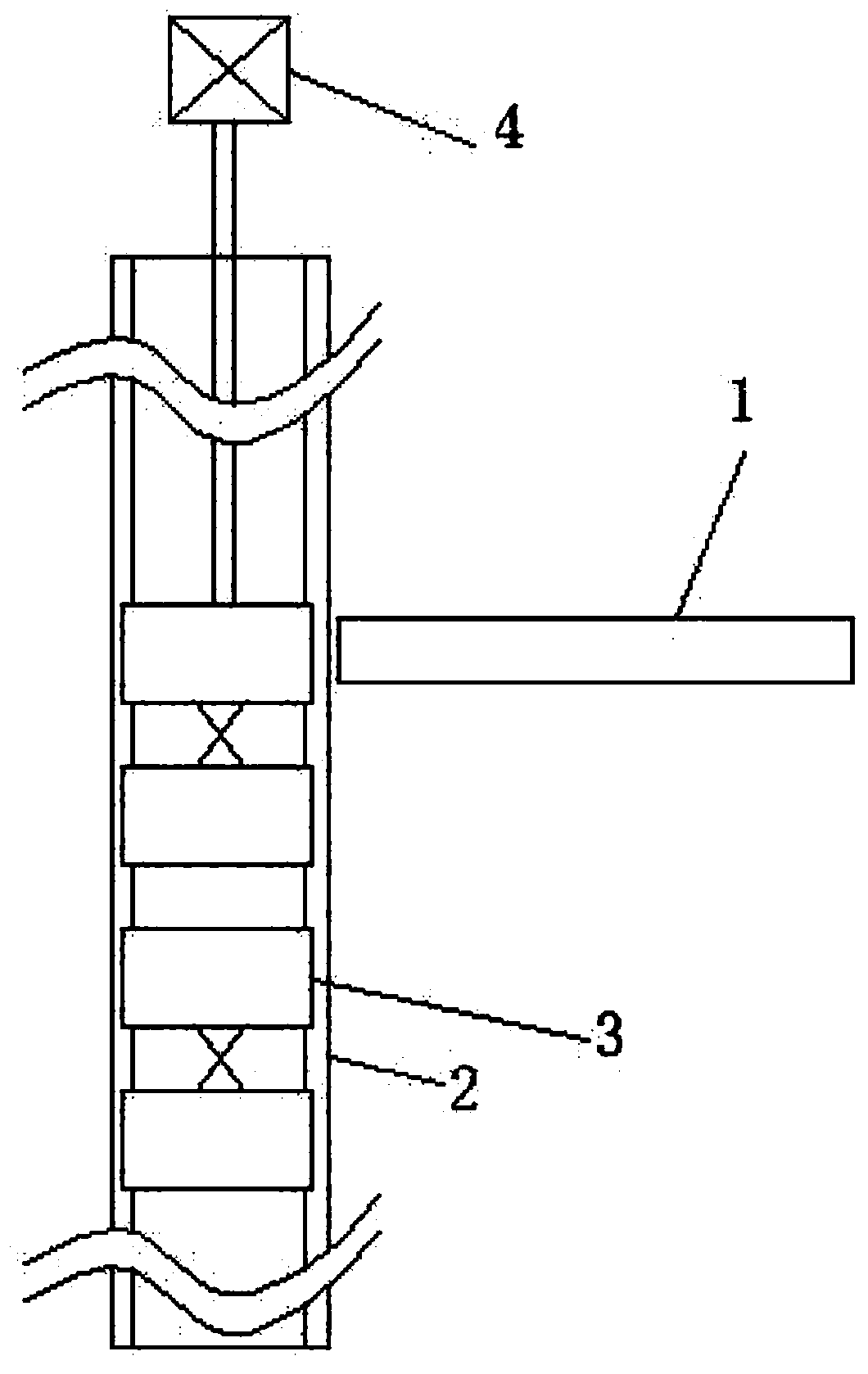

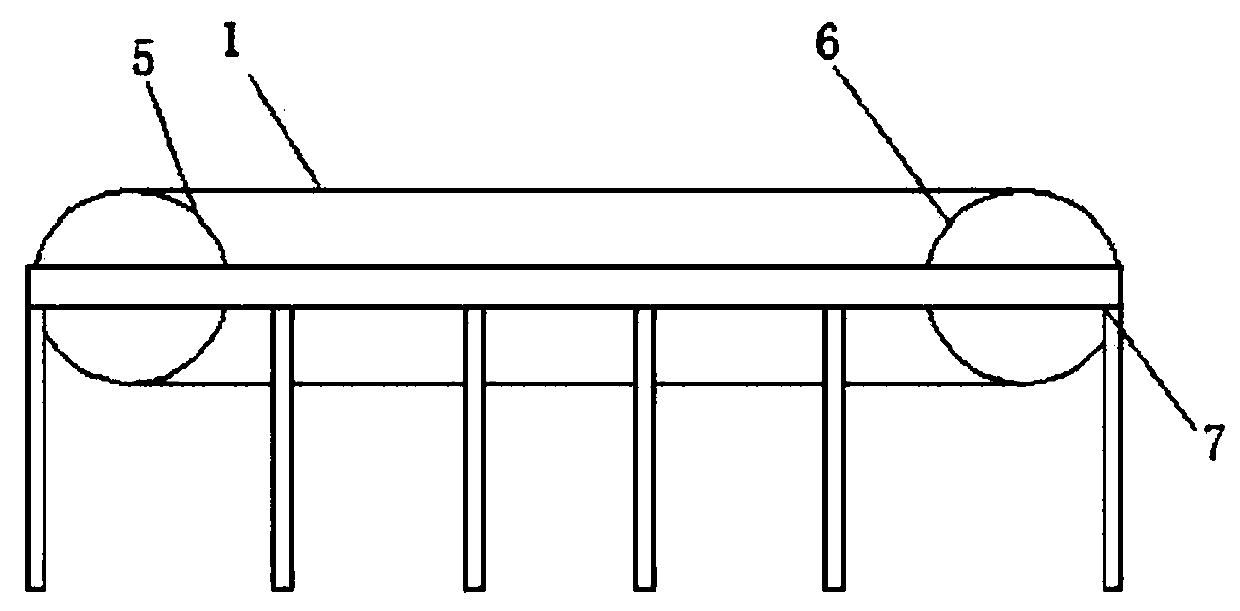

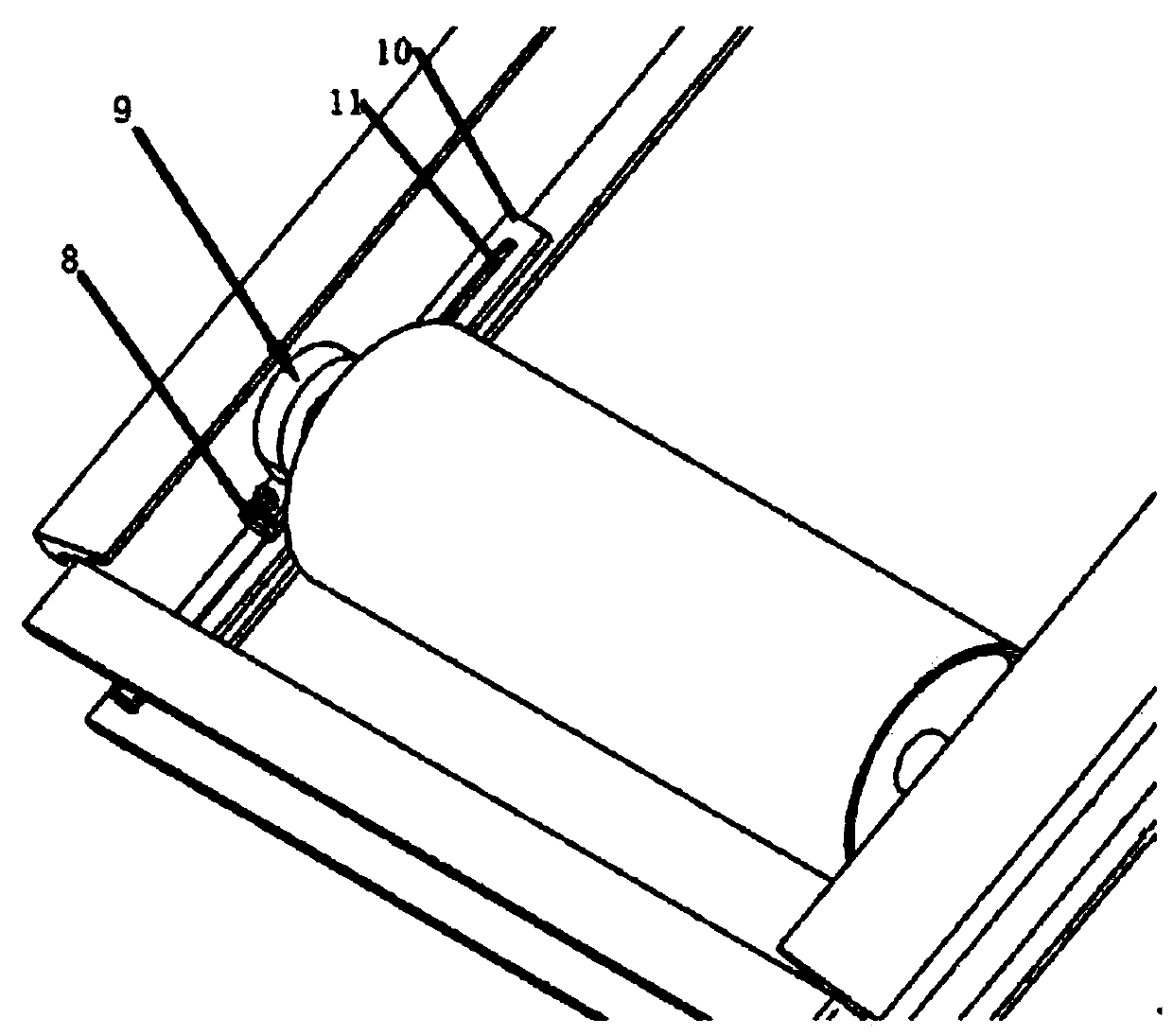

[0020] Embodiment: as shown in the figure, a kind of underground automatic conveying system, comprises the rake machine that is positioned at the head, also comprises belt conveyance part and mine car transport part; Described belt conveyance part comprises belt rack 7, is provided with Carrying roller, one end of belt frame 7 is provided with first roller 5, and the other end is provided with second roller 6, and described first roller 5 and second roller 6 are wound with transport belt 1; Stable car 4, track 2 on the ground, track 2 is provided with the mine car 3 of serial connection, the mine car 3 that is positioned at head in the mine car 3 of series connection is connected with stable car 4; The two ends of described transport belt 1 are respectively A feed end and a discharge end, the feed end communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com