AGV blanking mechanism

A sliding rail, horizontal expansion and contraction technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of poor promotion, low use value, low protection performance, etc., to meet the needs of use, high use value, The effect of high protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

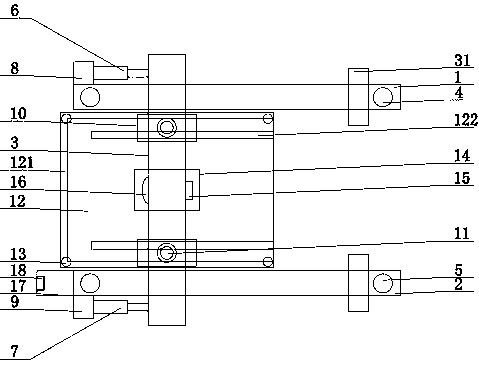

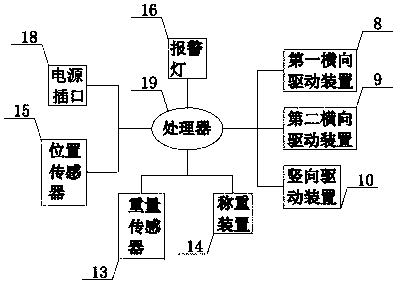

[0017] see Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes the first slide rail frame 1, the second slide rail frame 2, the third slide rail 3, the first stand 4, the second stand 5, the first transverse Telescopic rod 6, second lateral telescopic rod 7, first lateral drive device 8, second lateral drive device 9, vertical drive device 10, vertical telescopic rod 11, tooling plate 12, weight sensor 13, weighing device 14, Position sensor 15, warning light 16, control cabinet 17, power socket 18, processor 19, the second slide rail frame 2 is horizontally arranged on the right side of the first slide rail frame 1, and the first slide rail frame 1 right side is horizontally arranged There is a third slide rail 3 that is sleeved between the second slide rail frame 2, the first vertical frame 4 is arranged on the front and rear ends of the lower surface of the first slide rail frame 1, and the front and rear ends of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com