Pure magnesium molten iron spheroidizing station and control method thereof

A processing station and pure magnesium technology, applied in the field of pure magnesium iron hydrosphere processing station and its control, can solve problems affecting work efficiency, etc., and achieve the effects of improving work efficiency, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

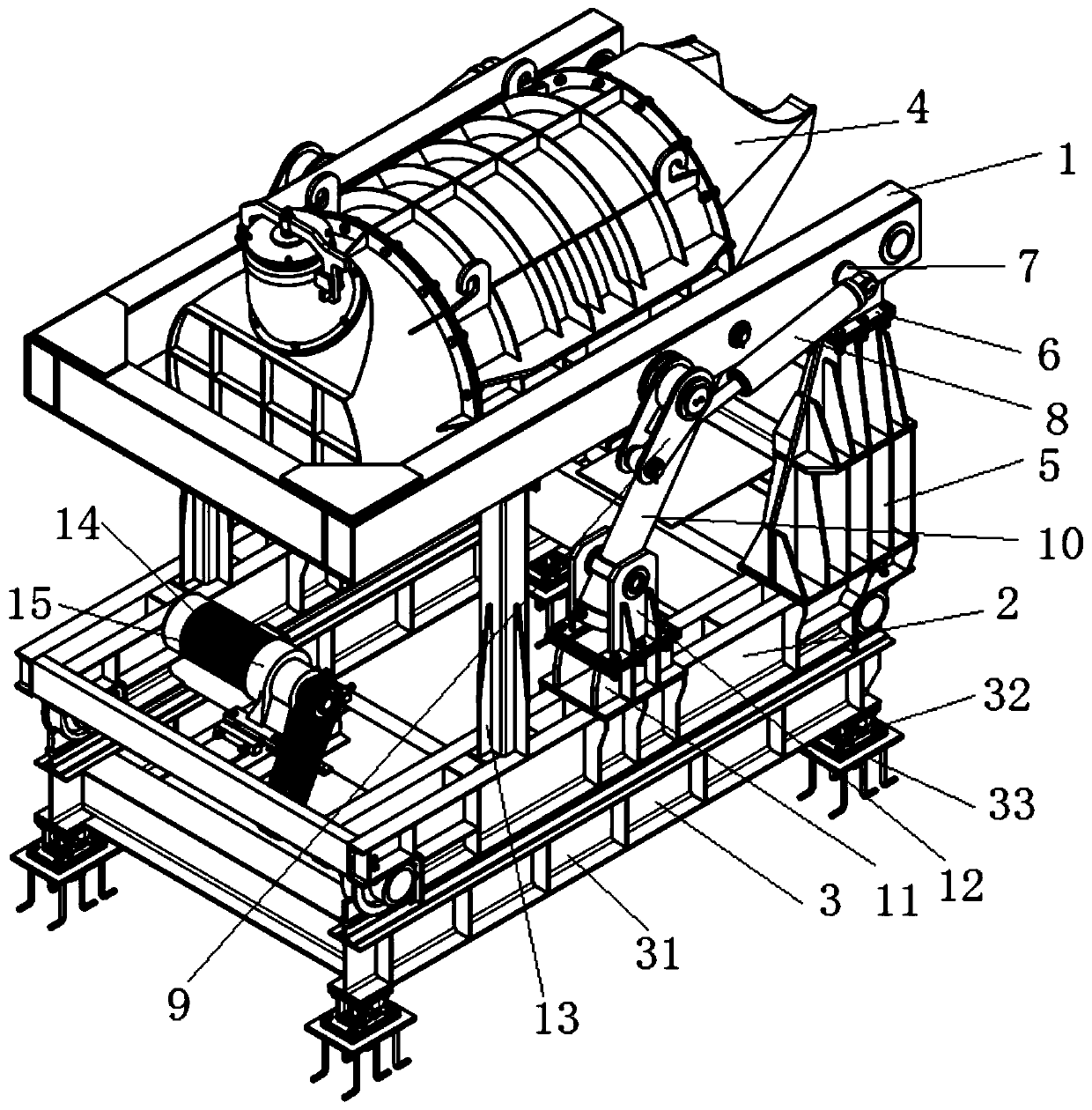

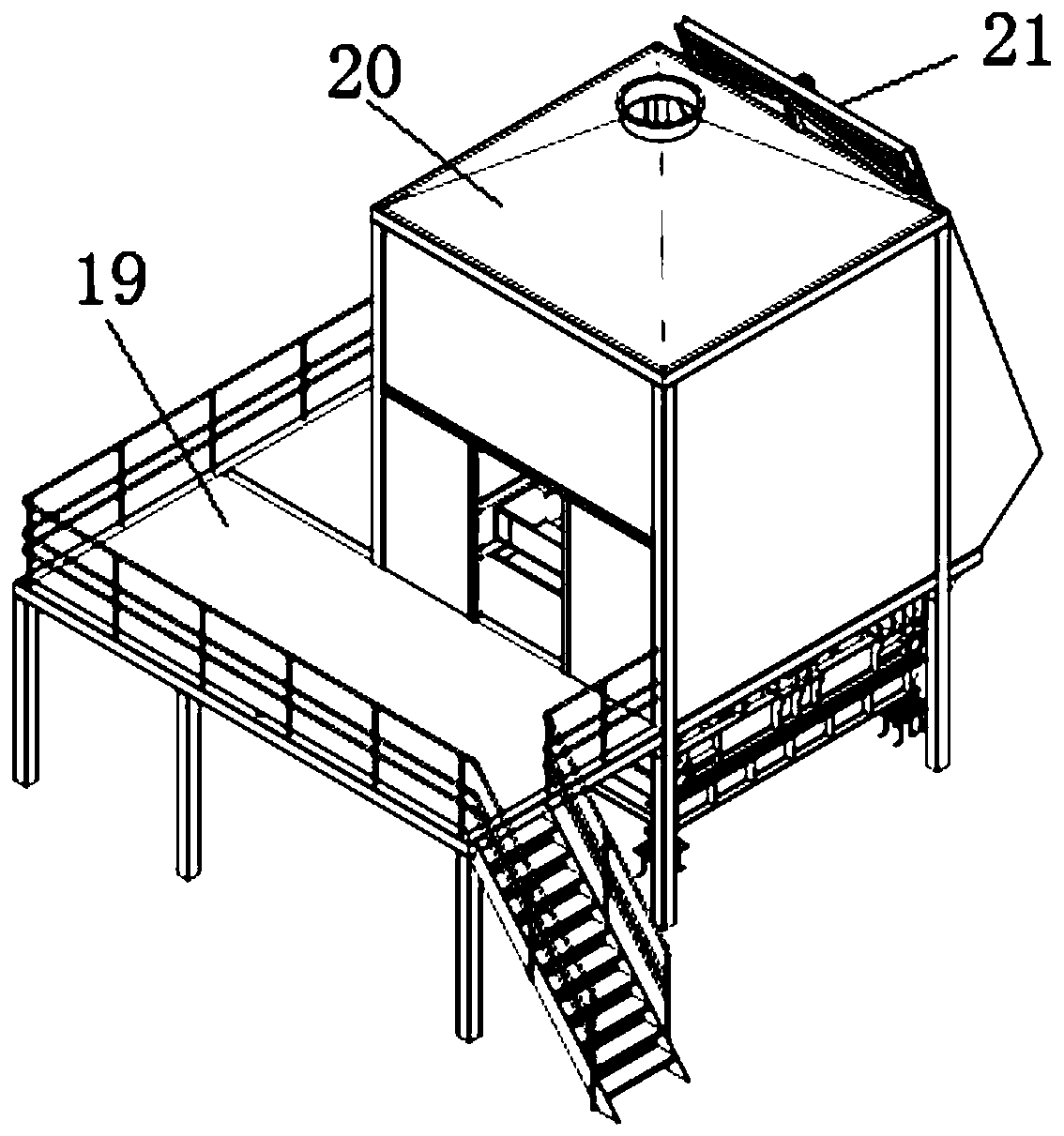

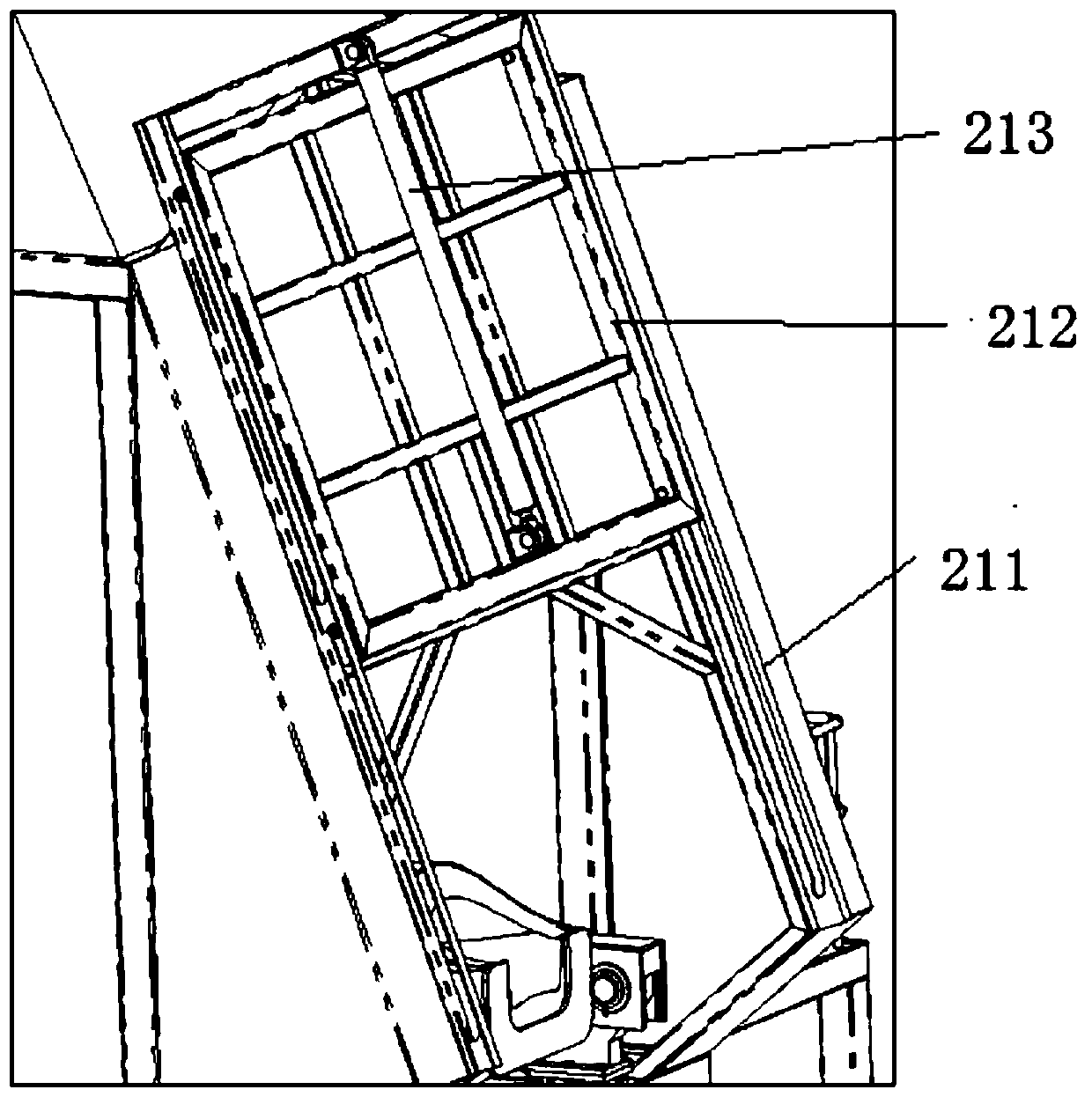

[0024] This pure magnesia ferrohydration processing station of the present invention comprises a trolley turning frame assembly, and the trolley turning frame assembly includes a turning frame 1 connected with a subpackage 4 and a vehicle frame 2 arranged below the turning frame 1, and the turning frame 1 Both sides are provided with the overturning device that drives the subpackage 4 to turn over to the side where the reaction chamber 44 is provided, and a swinging device that drives the subpackage 4 to swing towards the mouth of the subpackage is also provided between the overturning frame 1 and the vehicle frame 2. In this pure magnesium iron hydrosphere treatment station, the turning device can be used to realize the turning of the sub-basket 4, and the molten iron in the sub-basket 4 reacts...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap