Building sandwich thermal insulation board

A sandwich insulation board and insulation board technology, applied in the direction of insulation, building components, etc., can solve the problems of thick outer protective layer of insulation board, insufficient adhesion between walls, and waste of materials, so as to reduce man-days and construction Convenience and reduced storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

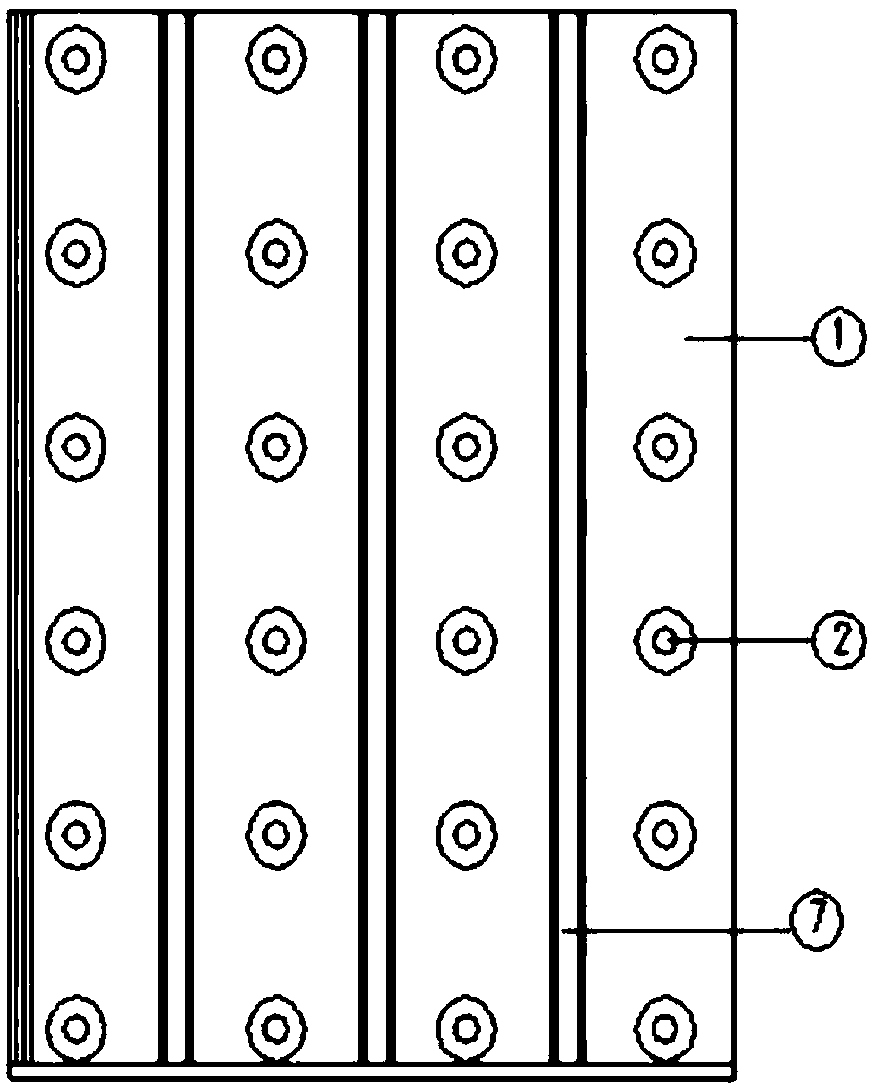

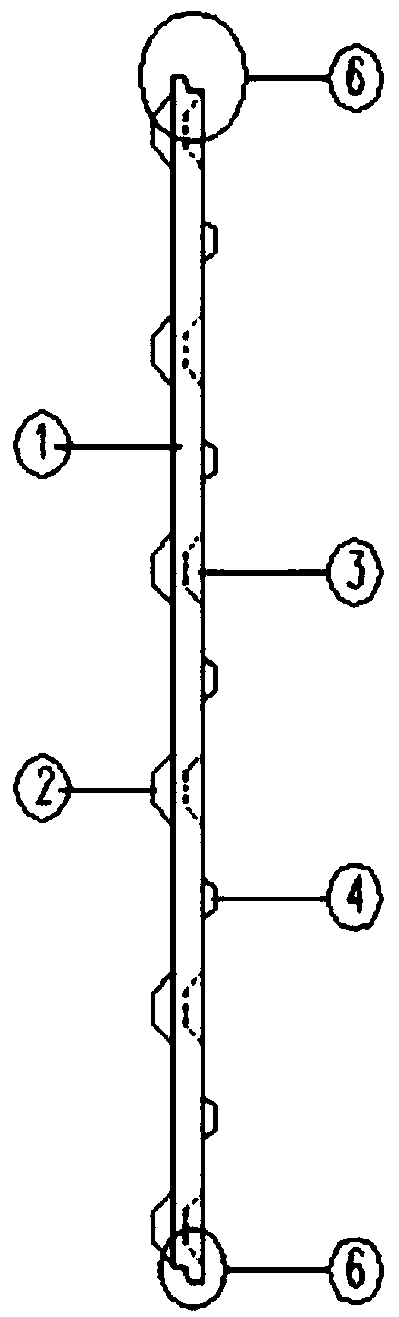

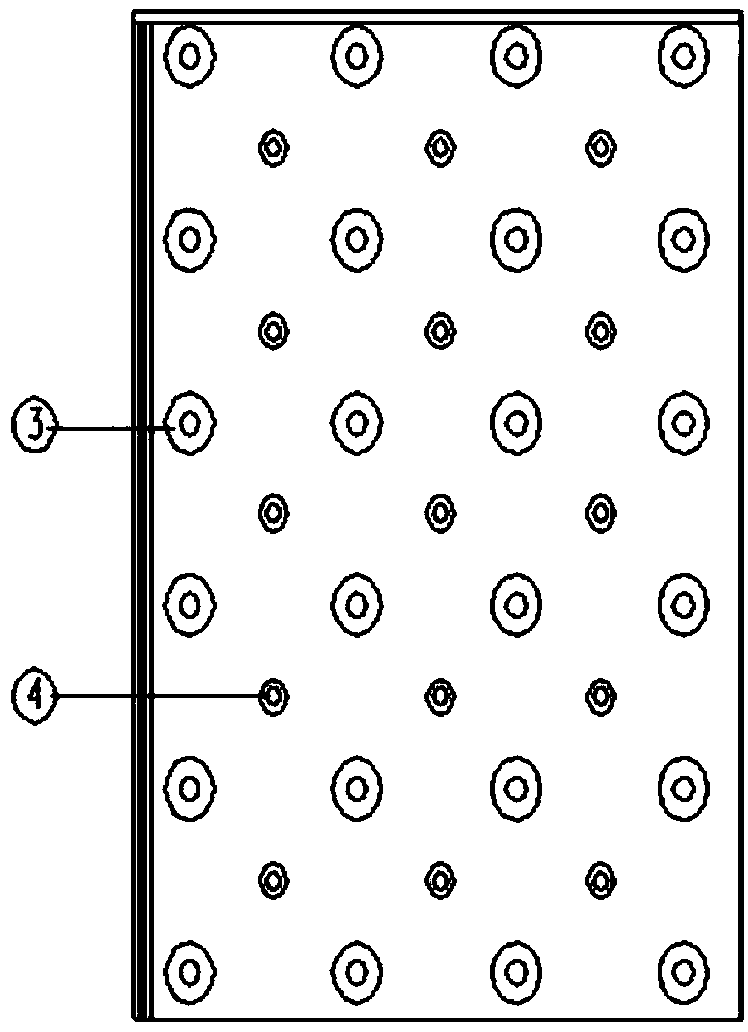

[0012] Attached below figure 1 , 2 , 3, 4 The present invention is described in detail: a kind of building sandwich insulation board, it comprises insulation board body 1, has a plurality of outer limit protrusions 2 evenly distributed on the outside of insulation board body 1, on the outside of insulation board body 1 There are a number of vertical grooves 7 on the outer surface distributed in the vertical direction, and a plurality of convex bodies 4 on the inner surface and concave bodies 3 on the inner surface are evenly distributed on the inner side of the insulation board body 1

[0013] Vertical splicing buckles 6 are respectively provided at both ends of the thermal insulation board body 1 in the vertical direction. Horizontal splicing hasps 5 are respectively provided at both ends in the transverse direction of the thermal insulation board body 1 .

[0014] Although the present invention has been described in detail above, it is not limited thereto. Those skilled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com