Wall climbing machine with transverse static friction propelling device

A technology of a propulsion device and a wall-climbing machine, which is used in cleaning machinery, machine parts, applications, etc., can solve problems such as increasing operating costs, and achieve the effect of reducing operating costs and avoiding personal safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

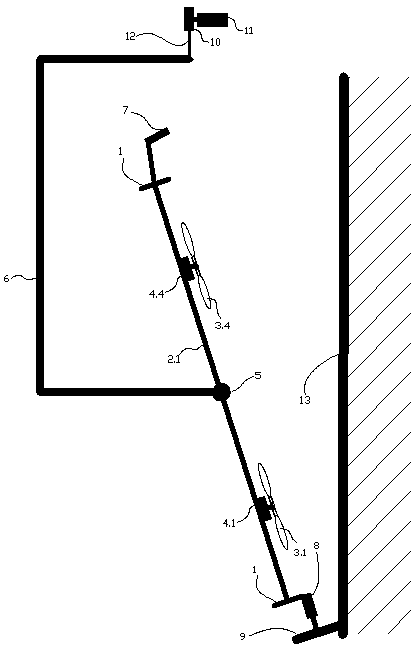

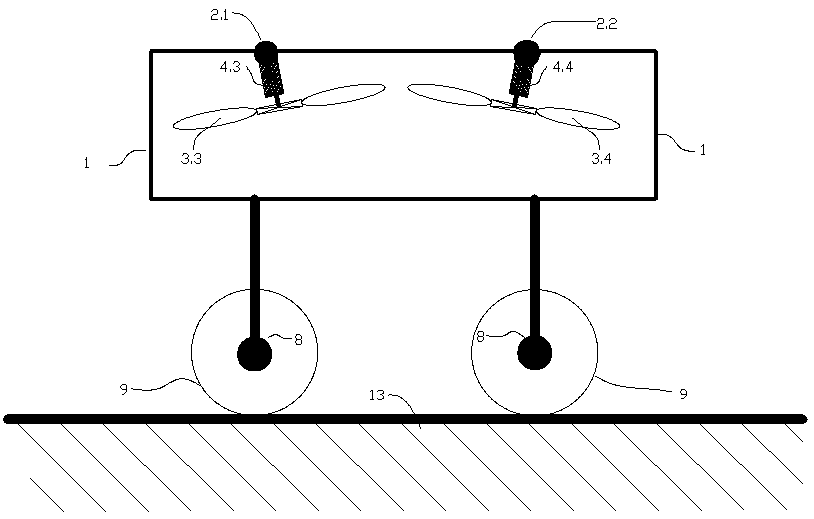

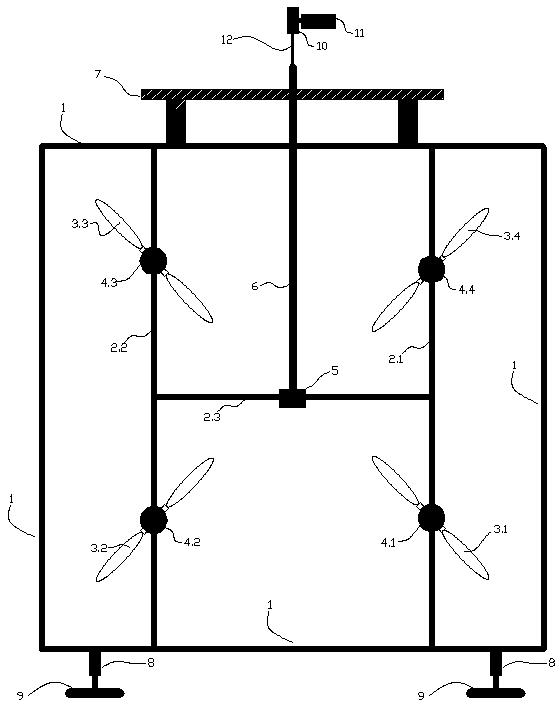

[0021] like figure 1 As shown, the wall climbing machine body (1) includes four propellers (3), and the rotation plane of the propellers (3) is located in the vertical plane (or slightly inclined), so the propellers (3) generate horizontal thrust when rotating. This horizontal thrust pushes the wall climbing machine body (1) to the wall body (13) to be climbed.

[0022] The motor drive device of the climbing machine (1) comprises a traction rope (10), a wheel (11) and a drive motor (12). Driven by the drive motor (12), the wheel (11) rotates, driving the climbing machine body (1) to move up and down.

[0023] The rigid structure (6) is subjected to the upward pulling force of the traction rope (10) and the downward pulling force of the wall climbing machine body (1), so the attitude is not easy to change, and can be used as a support for the attitude adjustment of the wall climbing machine body (1). By adjusting the attitude adjustment electric joint (5), the attitude adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com