Multi-station multifunctional machining lathe

A mechanical processing and multi-functional technology, applied in the direction of metal processing machinery parts, metal processing equipment, turning equipment, etc., can solve the problems of single function and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

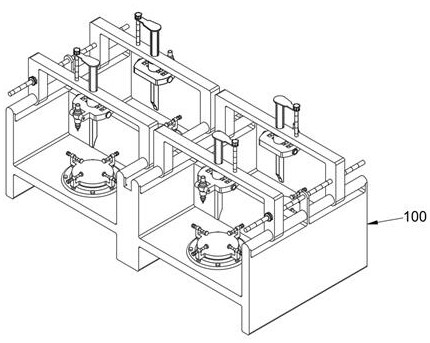

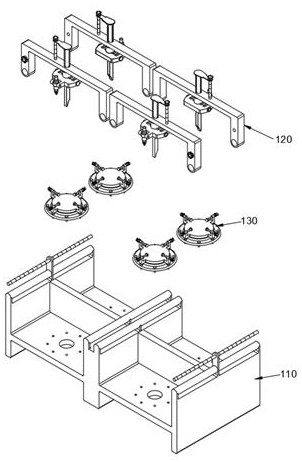

[0034] see Figure 1-Figure 6 As shown, the purpose of this embodiment is to provide a multi-station multifunctional machining lathe, including a processing bed 100, and the processing bed 100 at least includes:

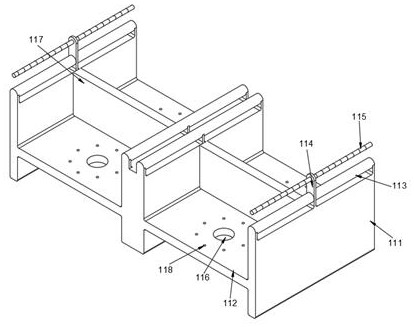

[0035] Placement body 110, placement body 110 comprises processing table 111, and processing table 111 is " H " type structure, and processing table 111 upper surface is provided with a plurality of processing chambers 112, and the top of processing table 111 is provided with slide shaft 113, and processing chamber 112 tops A power slot 116 is provided, and the power slot 116 is a cylindrical structure groove, and a fixed body 130 is arranged in the power slot 116;

[0036] The processing body 120, the processing body 120 includes a suspension 121, the suspension 121 is a "C"-shaped structure, the bottoms of both ends of the suspension 121 are provided with sliding openings 122 penetrating the surface, the sliding openings 122 are circular openings, sliding A slidin...

Embodiment 2

[0045] see Figure 7-Figure 9 As shown, while realizing simultaneous processing of multiple workpieces and having multiple processing capabilities, the fixation of the workpieces is ensured, and the following improvements are made on the basis of Embodiment 1:

[0046] Wherein, the fixed body 130 comprises a fixed disk 131 and a shielding body 132, the shielding body 132 comprises a shielding cover 138, the fixed disk 131 comprises a servomotor 133 positioned in the power slot 116, the top of the servomotor 133 is connected with a rotating disk 134 for rotation, and the rotating disk 134 The side is provided with a plurality of size connectors 135, the top of the size connector 135 is provided with a size thread groove 1351 that runs through its surface, the size thread groove 1351 is internally threaded with a size threaded rod 136, and one end of the size threaded rod 136 is provided with a contact body 1361 , by being provided with the size thread groove 1351, the size thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com