YZ-type pipeline beveled-joint assembly used for fluid delivery

A fluid transportation and pipeline technology, applied in the field of YZ-type pipeline miter components, can solve the problems of delayed fluid transportation and reduced fluid transportation efficiency, and achieve the effects of simple structure, convenient use and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

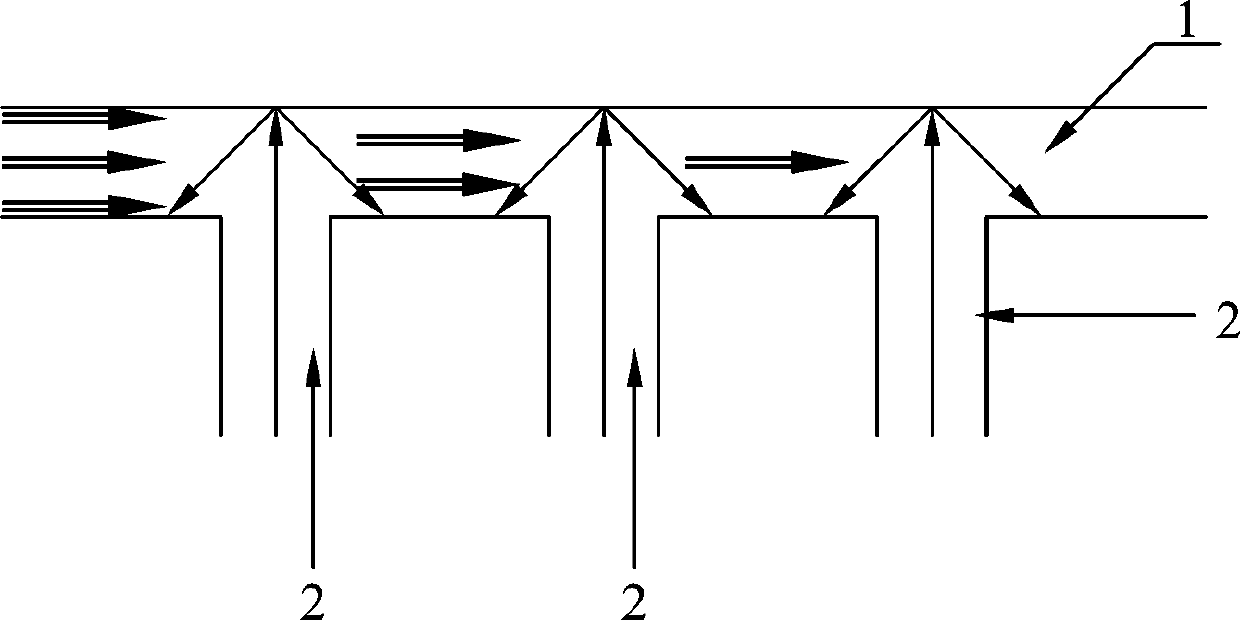

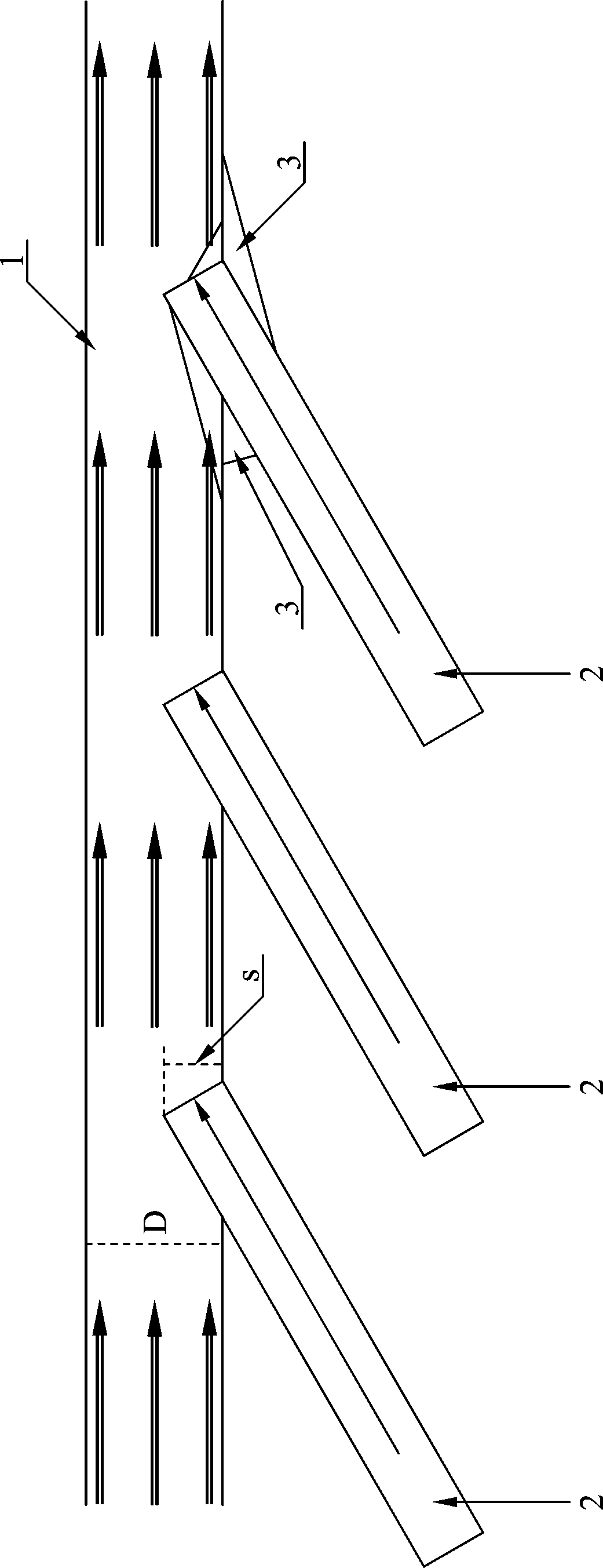

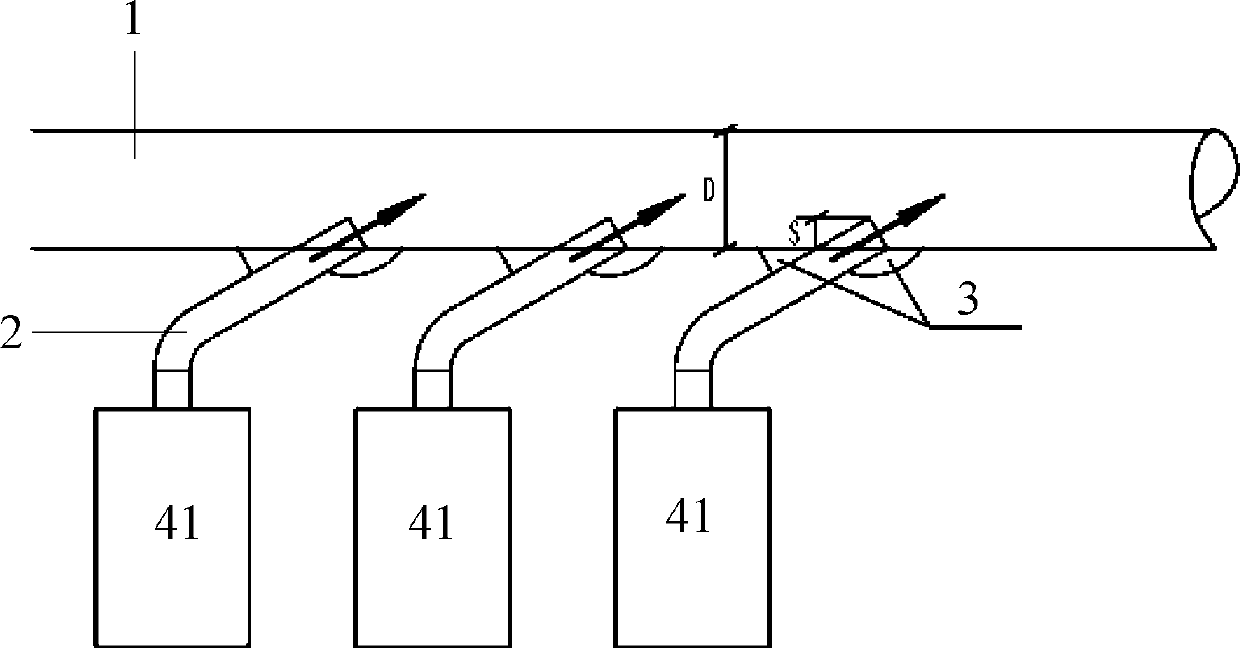

[0025] A YZ-type pipe miter assembly for fluid delivery, including a main pipe 1, a branch pipe 2 and a reinforcement block 3, such as figure 2 As shown, the specific structure is:

[0026] One end of each branch pipe 2 is connected with the main pipe 1 and sealed. The inner end of the branch pipe 2 is inserted into the main pipe 1. The angle between the branch pipe 2 and the main pipe 1 is 15°-45°. The acute angle between the branch pipe 2 and the main pipe 1 is The apex of is facing the direction of fluid delivery in the main pipe 1; if the inner diameter of the main pipe 1 is D, and the distance between the apex of the inner end of the branch pipe 2 and the inner wall of the main pipe 1 is s, then s≤1 / 3D.

[0027] In this embodiment: the connection between the branch pipe 2 and the main pipe 1 is fixed by welding, and a reinforcement block 3 is welded to prevent the branch pipe 2 and the main pipe 1 from tearing. A reinforcement block 3 is welded at each included angle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com