Optical fiber and GNSS-based high-precision wide-range three-dimensional deformation monitoring device

A technology of three-dimensional deformation and monitoring devices, which is applied in the direction of measuring devices, optical devices, electromagnetic measuring devices, etc., can solve the problems of larger sensor size, inability to monitor, and inability to obtain three-dimensional deformation, so as to prevent fiber breakage, The effect of large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

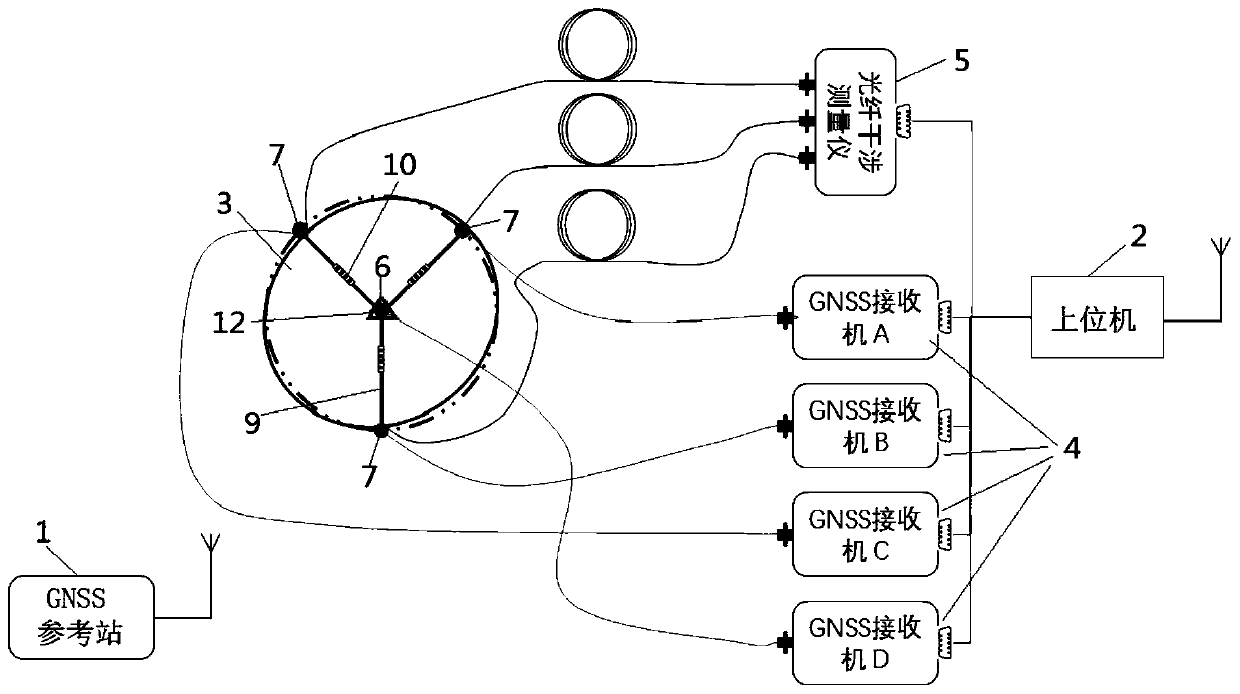

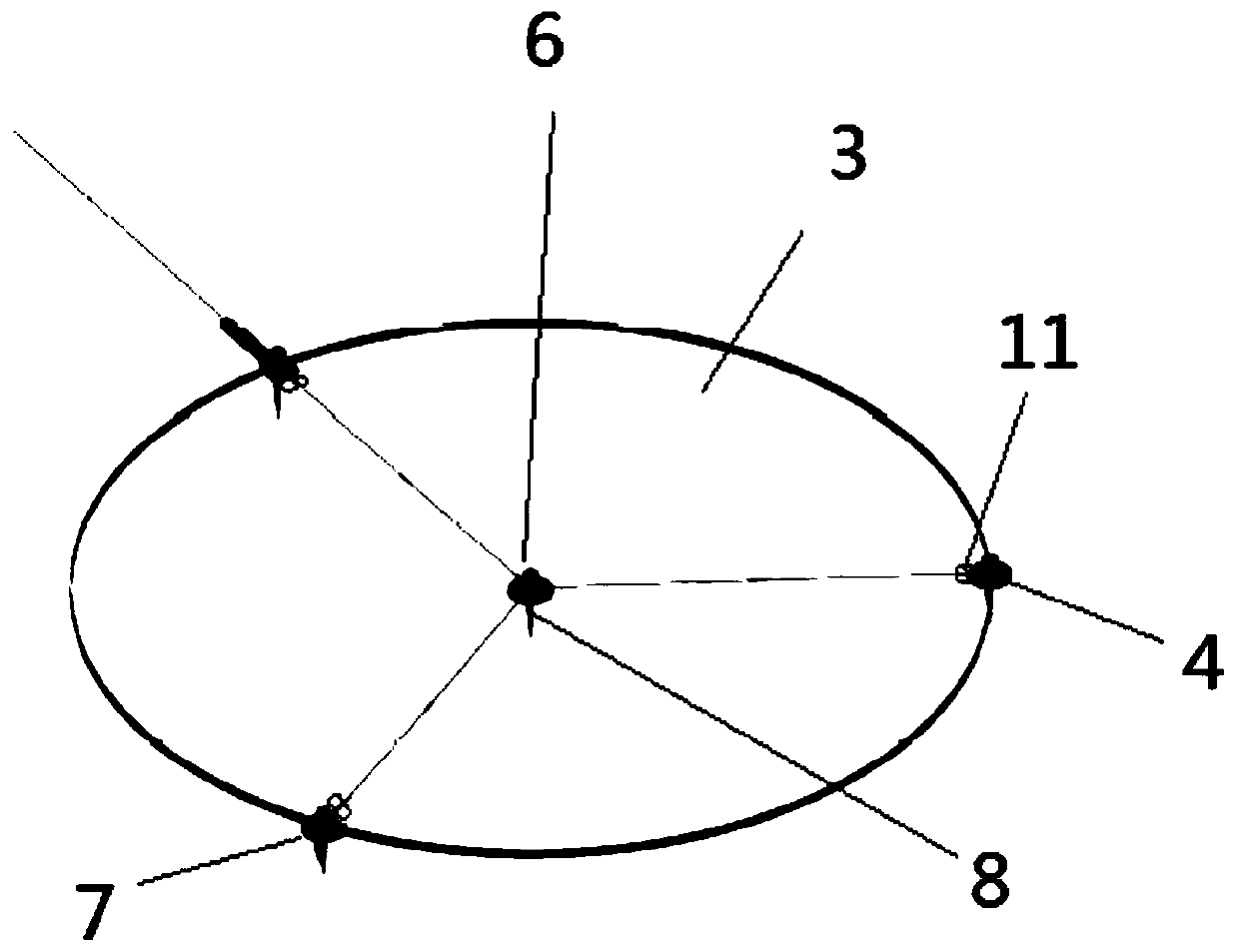

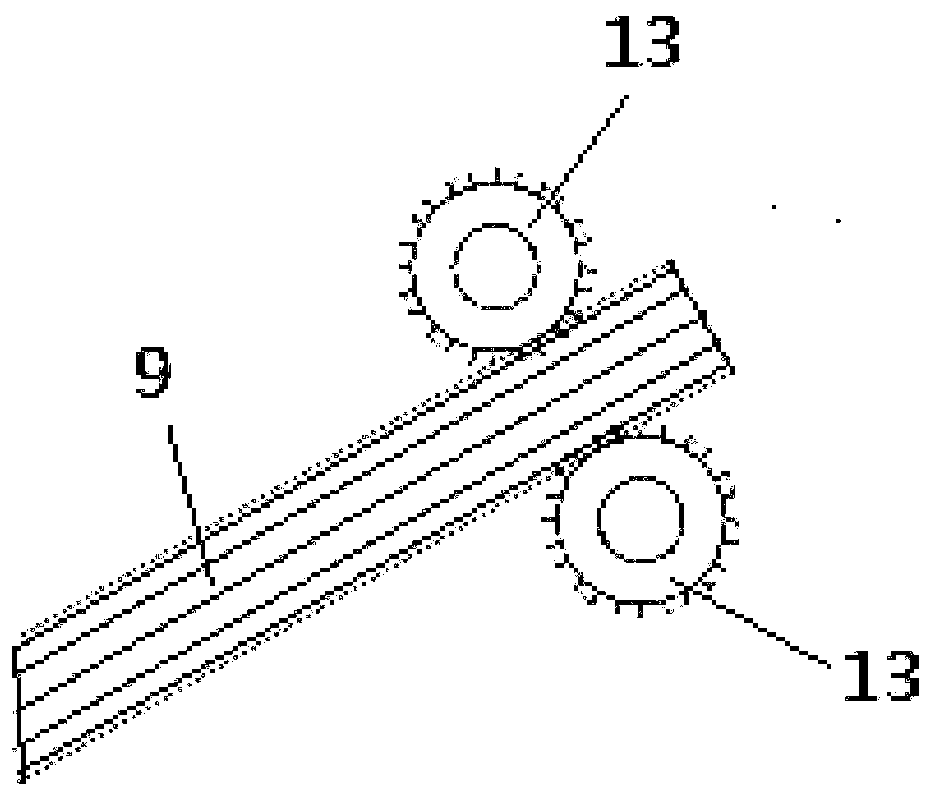

[0022] Such as figure 1 , figure 2 , image 3 As shown, a high-precision and large-range three-dimensional deformation monitoring device based on optical fiber and GNSS includes a GNSS reference station 1, a host computer 2, a substrate 3, four GNSS receivers 4, and an optical fiber interferometer 5. The substrate 3 is provided with a central lead contact 6 and three peripheral lead contacts 7 surrounding the central lead contact 6, and the central lead contact 6 and the three peripheral lead contacts 7 are all provided for contact with the measured object. A fixed fastening device 8, such as a rivet, the three peripheral lead contact points 7 and the central lead contact point 6 are connected to form a Y shape through an optical fiber 9 and a grating sensor 10, and the substrate 3 is also provided for adjustment A device 11 for automatically adjusting the length of each side of the Y-shaped optical fiber 9, the four GNSS receivers 4 are respectively arranged at the central le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com