Assistant decision-making method for gas sensor adjustment on working face

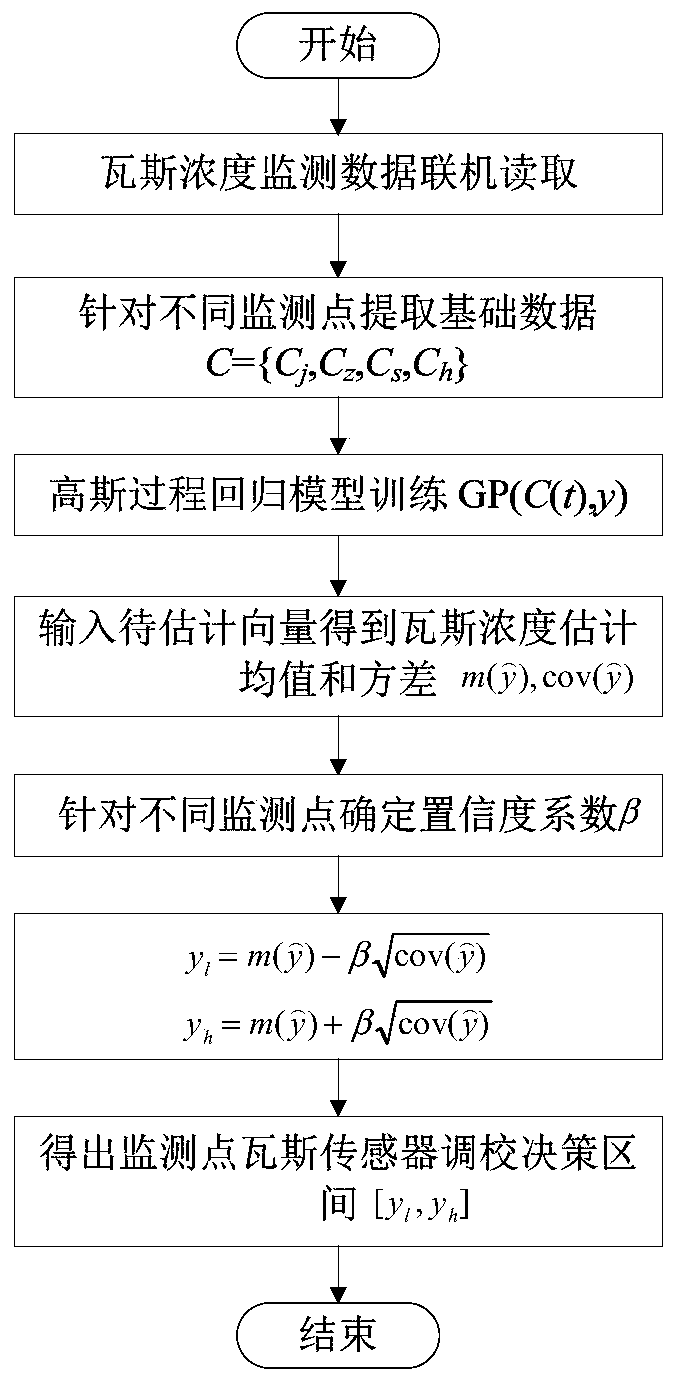

A gas sensor and auxiliary decision-making technology, which is applied in the field of gas sensor adjustment auxiliary decision-making in the working face, can solve the problems of continuous and intermittent gas concentration monitoring data, limited experience in sensor adjustment, and monitoring failure, so as to improve accuracy and work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

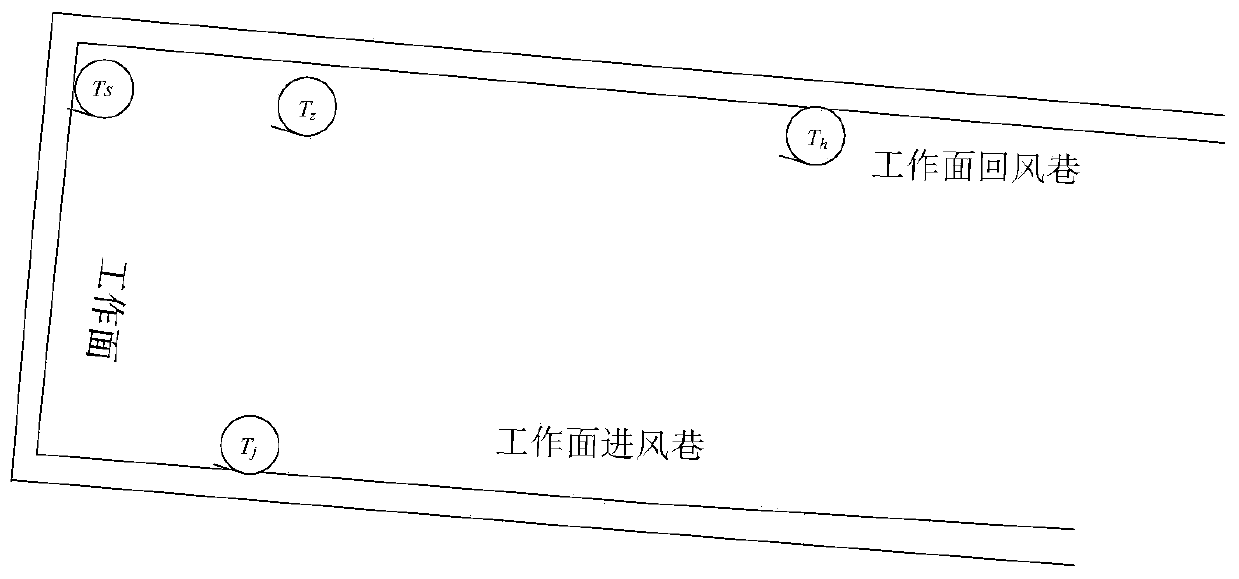

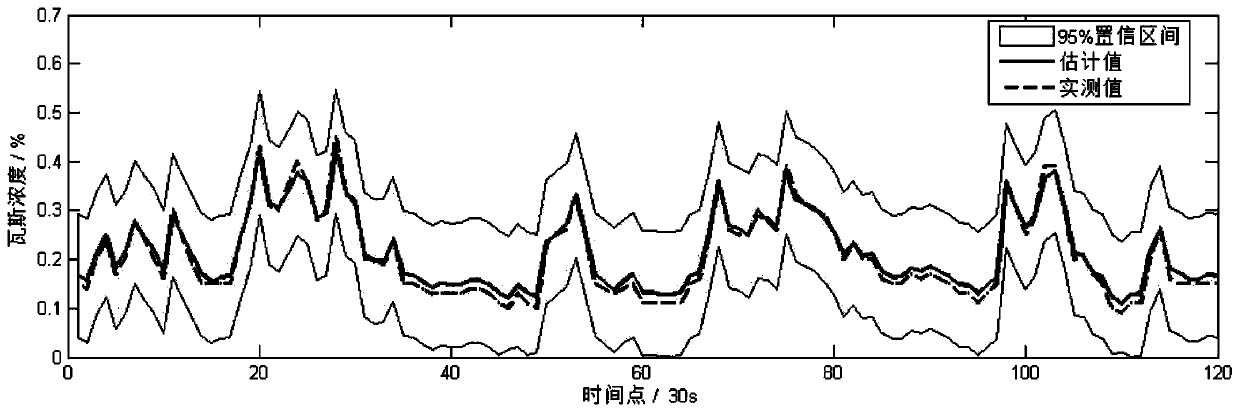

[0085] Reference attached figure 2 , 3 shown, with figure 2 It is the layout diagram of the gas sensor in the working face area, T j is the gas monitoring point of the air inlet lane, T s is the gas monitoring point in the upper corner, T z is the gas monitoring point of the working face, T h It is the gas monitoring point of the return airway; the monitoring point T of the mining face of a mine in Huangling, Shaanxi is selected z The point is used as the decision calculation object, and the attached image 3 The calculation results shown in the figure are based on the historical gas concentration monitoring data of the mine working face in 2017 as the basic data for modeling, and then the confidence interval of the gas concentration at 1 o'clock on January 1, 2018 is obtained. The gas monitoring period in this time period 30s, with a total of 120 data points, the air inlet lane T of the working face is selected in the modeling process j , upper corner T s , and work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com