Method of producing radioactive seed source core by electrohydrodynamic micro-droplet ejection

A technology of droplet spraying and production method, which is applied in radioactive sources, X-ray/γ-ray/particle irradiation therapy, nuclear engineering, etc., can solve the problems that will affect the accuracy of radioactive measurement, waste radioactive liquid, pollute the surrounding environment, etc. Achieve the effect of reducing radioactive pollution, reducing waste and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail

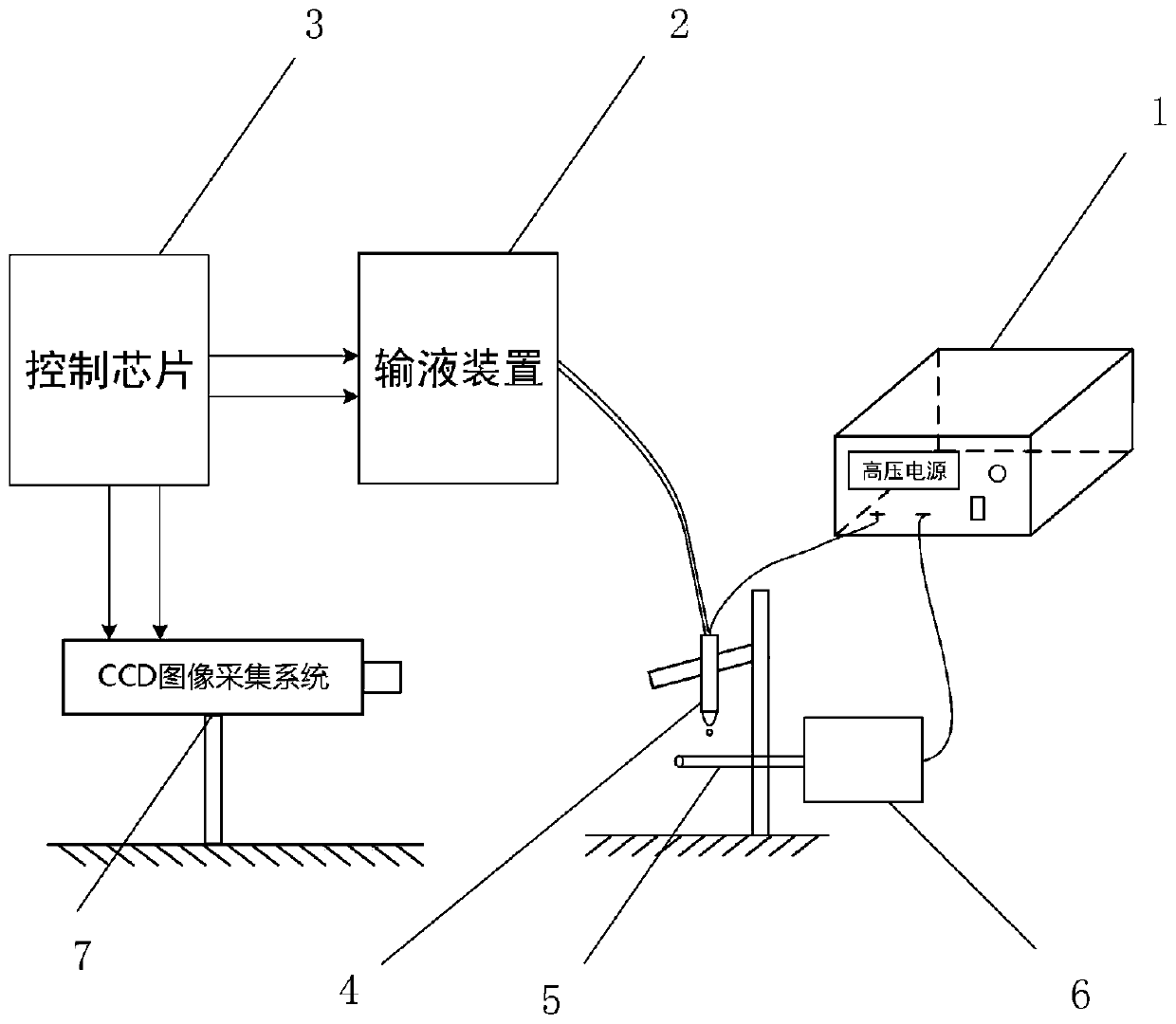

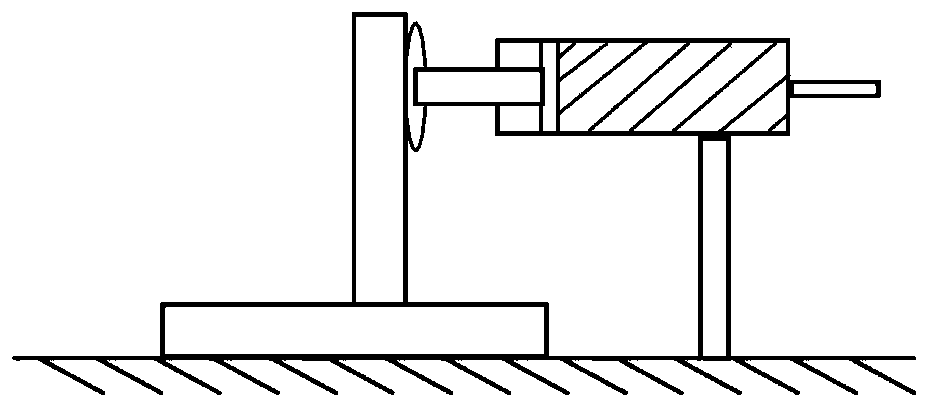

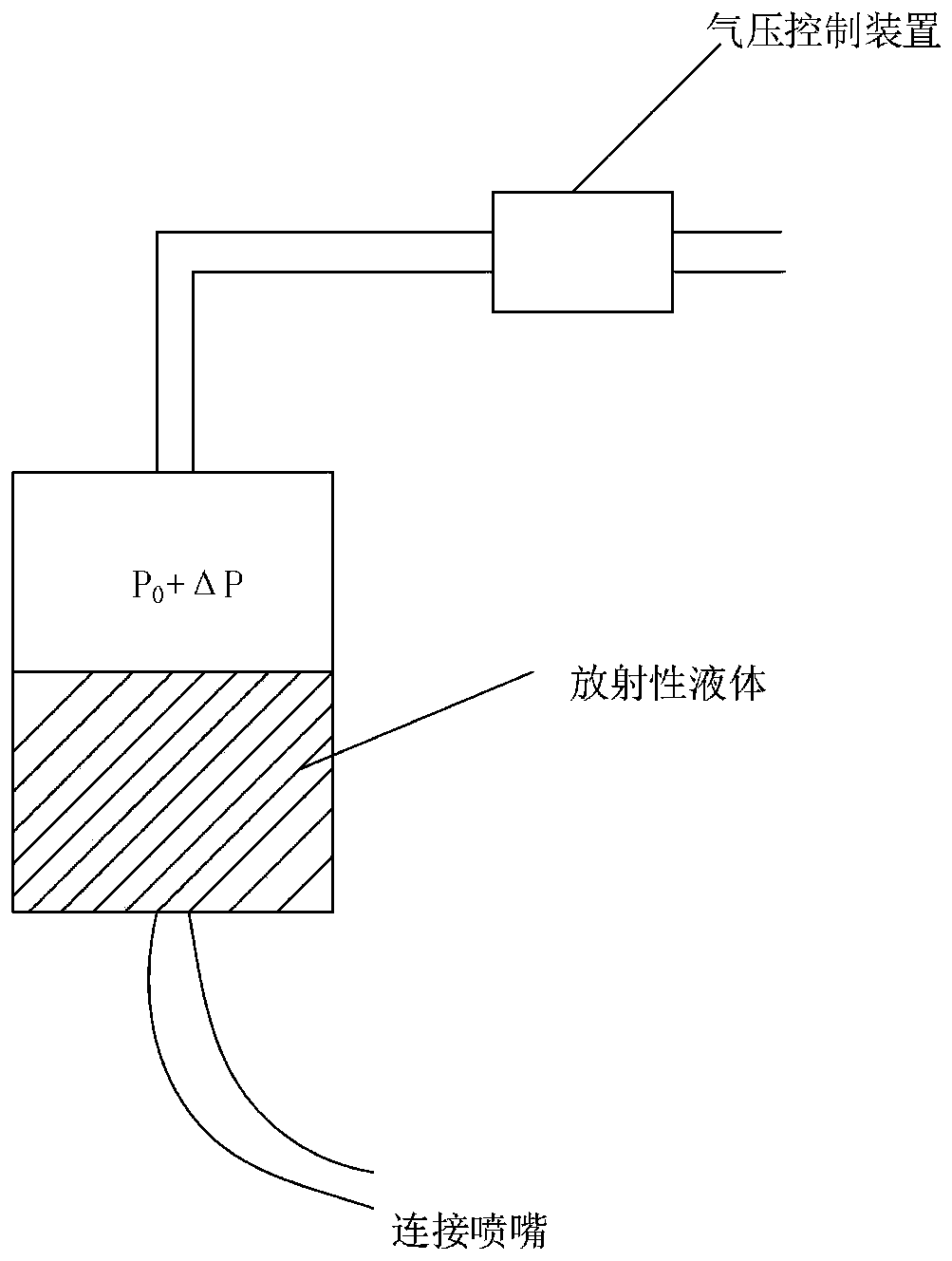

[0032] Such as figure 1 As shown, use a syringe pump to control the supply of radioactive solution under the control of a computer or other controllers. The positive pole of the power supply 1 is applied to the conductive nozzle 4, and the negative pole is applied to the conductive filament 5. By applying a voltage, an electrostatic potential difference is introduced. As the voltage increases, the solution on the conductive nozzle 4 will become a hemispherical or ellipsoidal meniscus droplet; as the voltage of the power supply 1 increases gradually, the surface charge density of the solution on the conductive nozzle 4 increases, and the electric field force increases. big. When the power supply 1 continues to increase and the electrostatic force and gravity exceed the surface tension, the droplet will leave the conductive nozzle 4. Since the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com