Extrusion type slit coating packaging equipment

A technology of slit coating and encapsulation equipment, which is applied to the device and coating of surface coating liquid, which can solve the problems of troublesome preparation work, pattern transformation is not as flexible as dispensing form, etc., and achieves strong applicability and improved The effect of coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

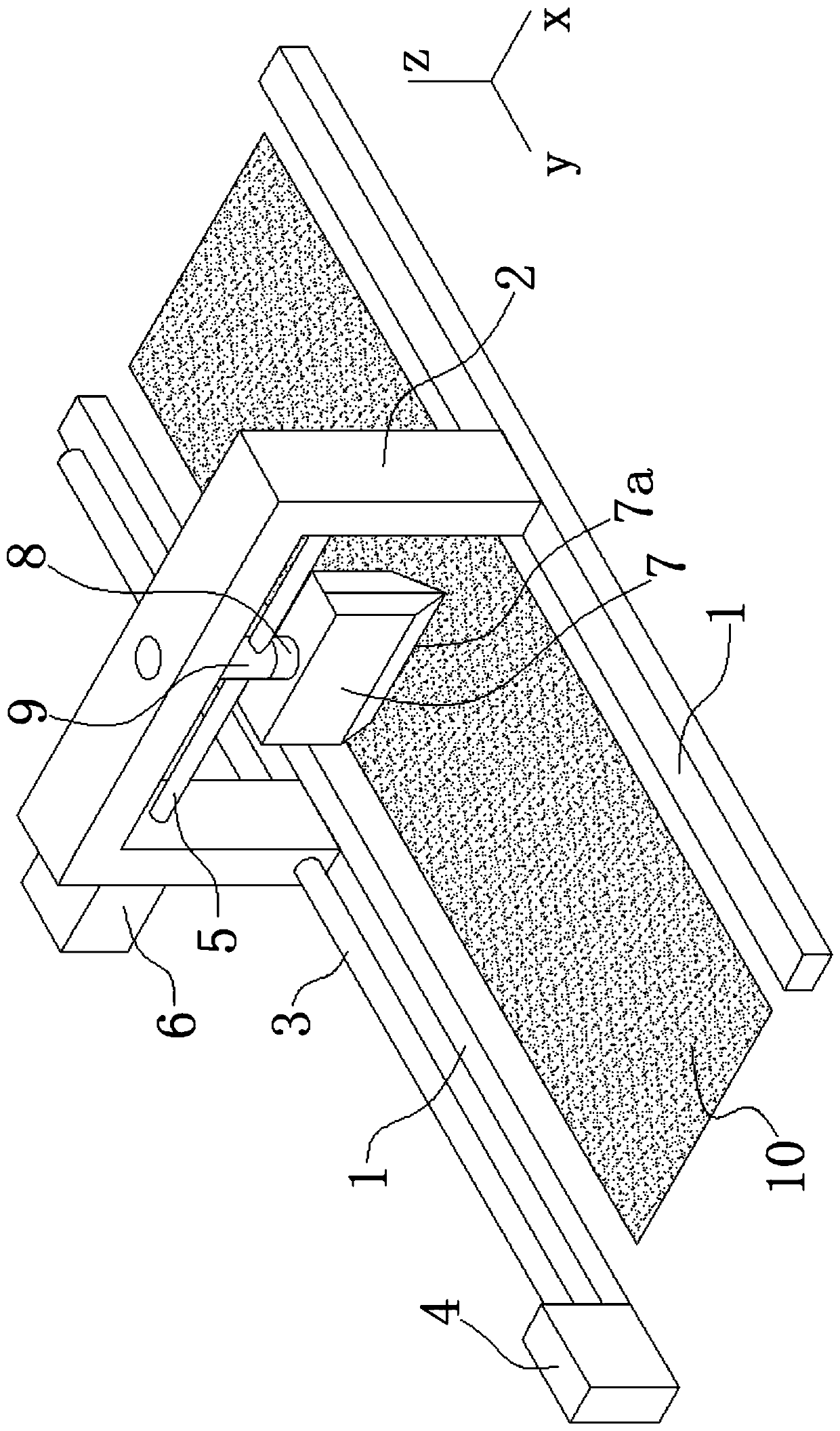

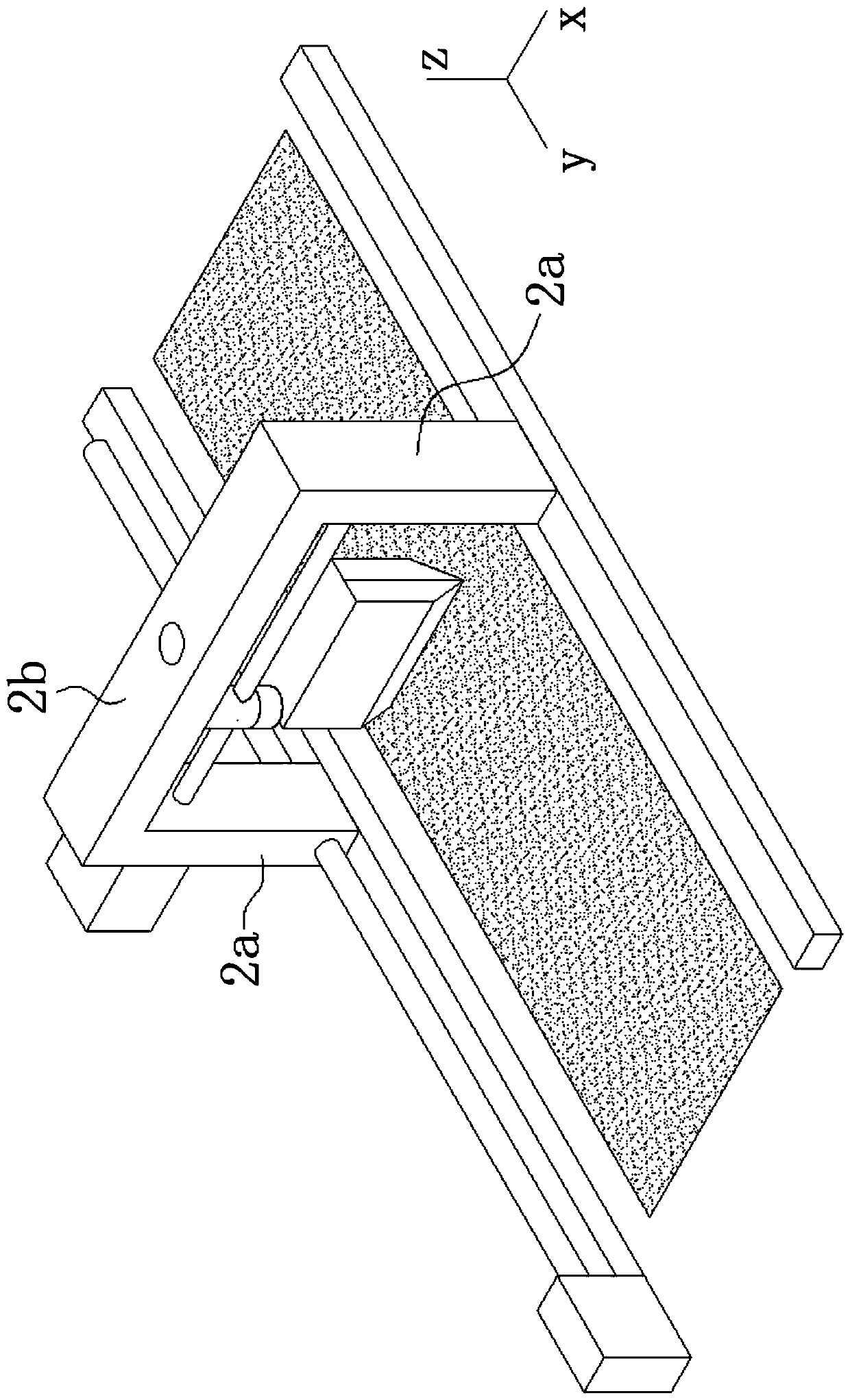

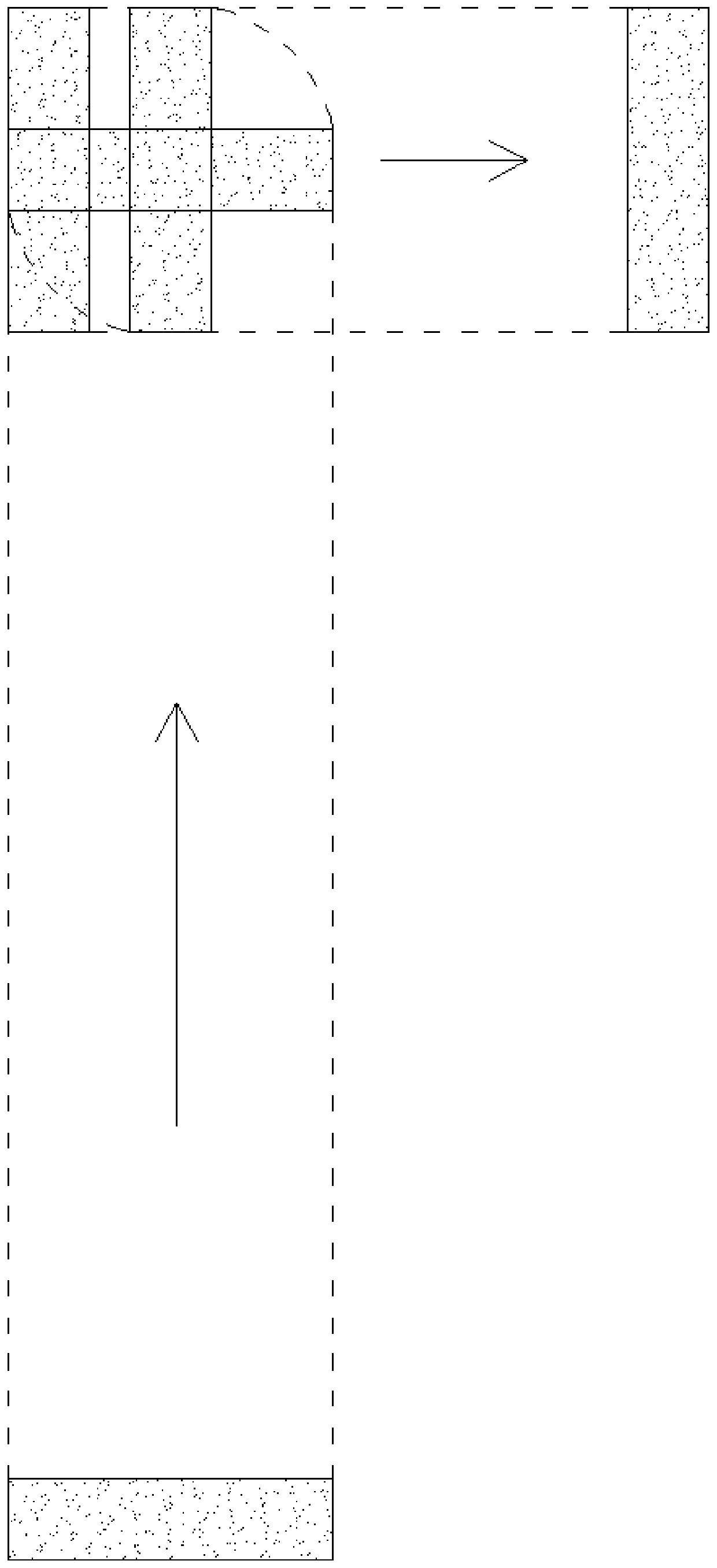

[0029] In order to achieve the purpose of the present invention, a kind of extrusion type slit coating encapsulation equipment comprises: coating system, possesses coating die head 7, and the bottom of coating die head 7 is provided with discharge slot 7a; Motion control system, makes The coating system has a degree of freedom of translation along the horizontal plane, a reciprocating linear degree of freedom in the vertical direction, and a degree of freedom of rotation around the vertical line. The motion control system includes a horizontally arranged and mutually perpendicular first screw rod 3, a second The screw mandrel 5, the motion control system also includes a telescopic shaft 8 connected to the top of the coating die head 7, the telescopic shaft 8 has a vertical telescopic degree of freedom and a rotational degree of freedom around its own axis; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com