Manufacturing process of gas-liquid separator welding tool

A gas-liquid separator and welding tooling technology, applied in the field of refrigeration, can solve the problems of cumbersome use of tooling, large space occupation, low positioning accuracy, etc., and achieve the effects of reducing manufacturing processes, smooth sliding, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

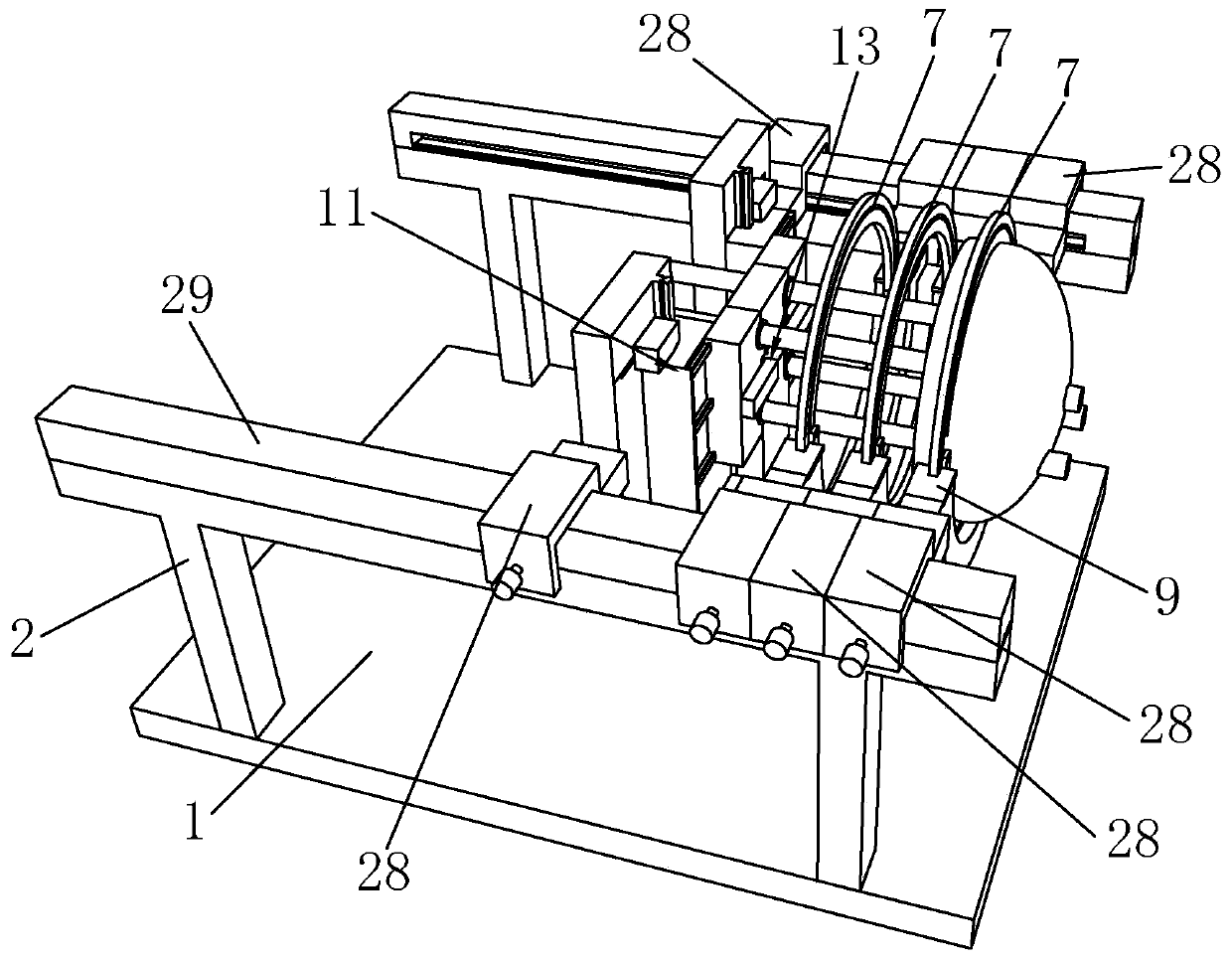

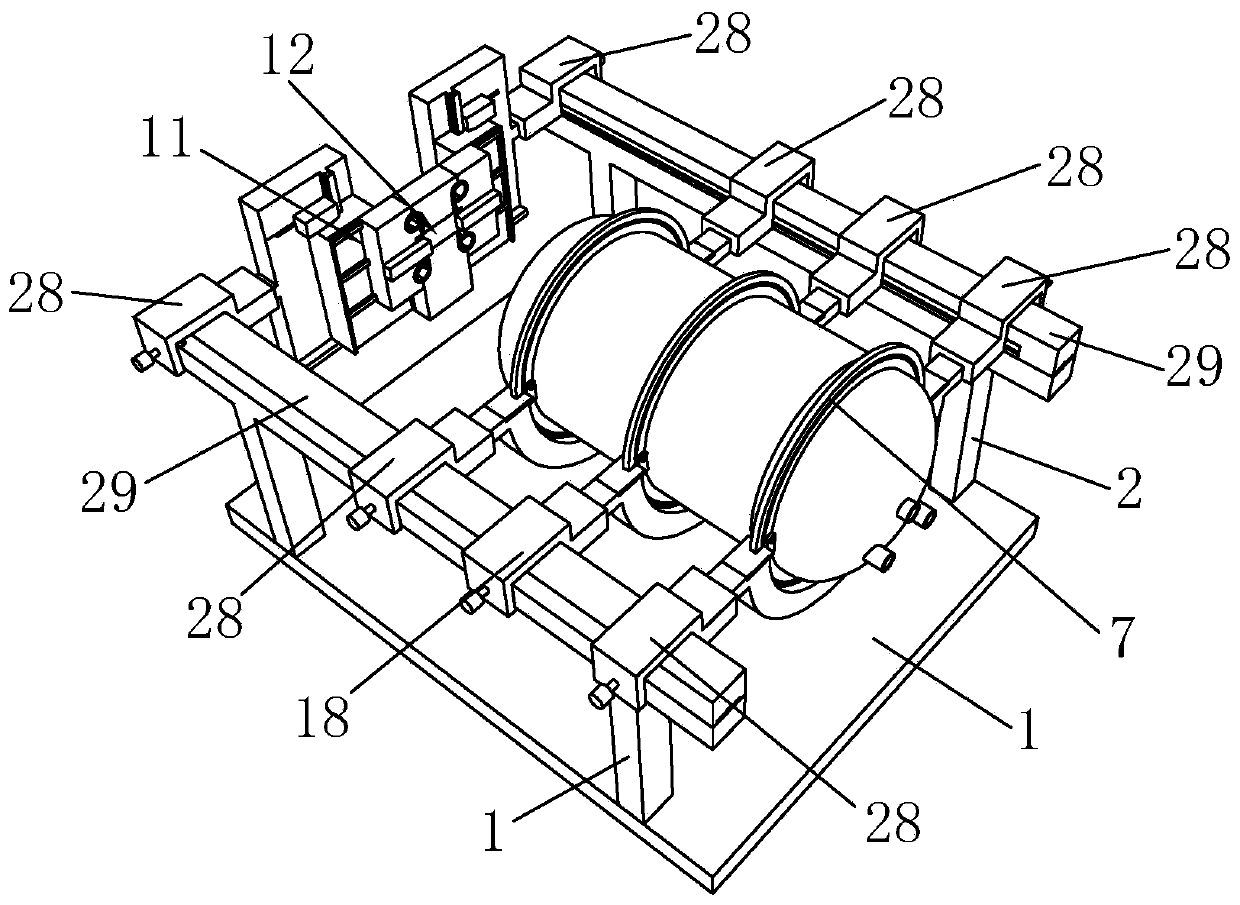

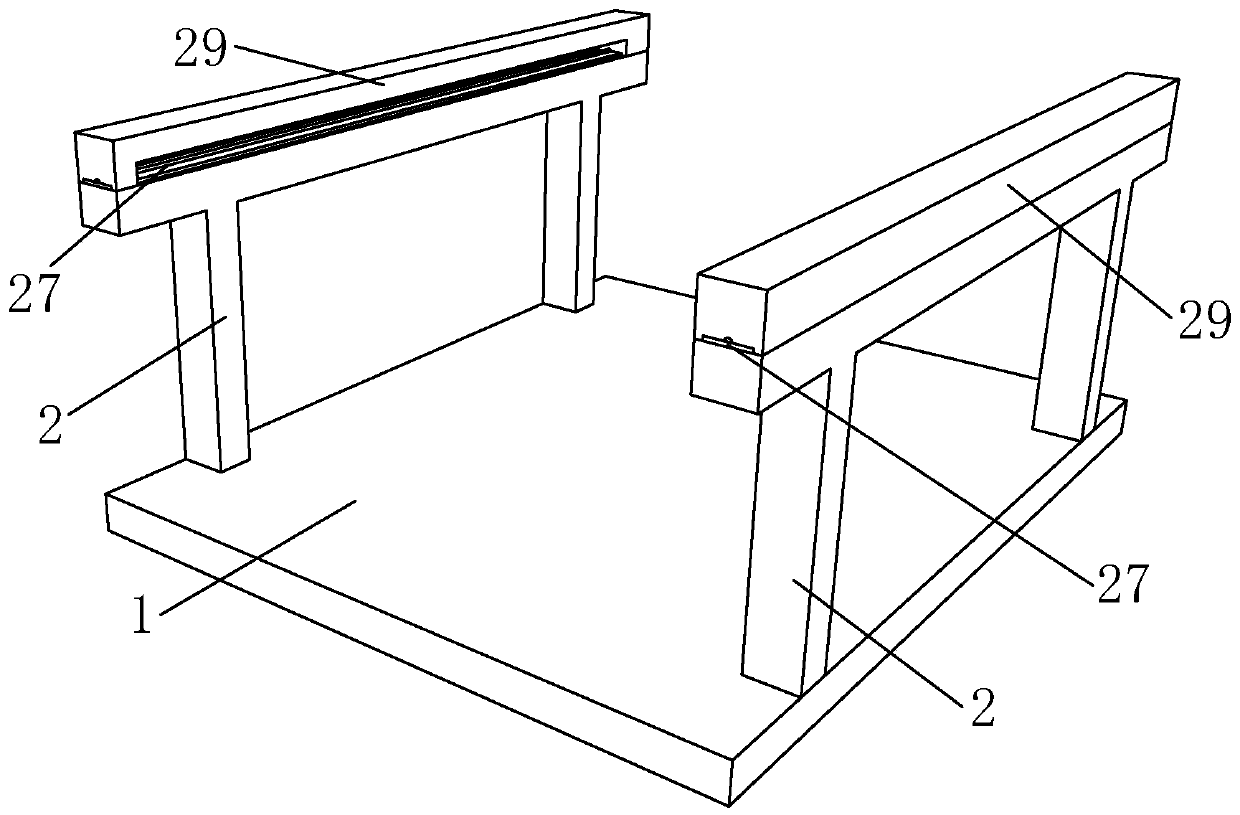

[0051] Such as Figure 1 to Figure 16 Shown, be the gas-liquid separator welding frock manufacturing process of the present invention, comprise the steps:

[0052] a. Base processing:

[0053] 1) Manufacture of the support frame 2: cutting the steel, and then welding the cut steel to form the support frame 2. When welding, use a square to assist welding to ensure that the horizontal bars and vertical bars of the support frame 2 are perpendicular to each other. Guarantee the manufacturing specifications of the support frame 2, and prevent the welding tooling from not sliding smoothly between the ring-shaped block 5 and the fixed plate 13 on the support frame 2 due to the non-perpendicularity between the horizontal bar and the vertical bar of the support frame 2, resulting in that when the gas-liquid separator is clamped Insufficient precision leads to a decrease in the quality of the gas-liquid separator.

[0054] 2) Base welding: Put the auxiliary positioning device 3 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com