Iron ball rocker arm processing and quality detecting integration process

An integrated, iron ball technology, applied in the field of processing quality inspection, can solve the problems of not being able to produce iron ball rocker arms, random processing without inspection, waste of raw material energy, etc., to reduce the probability of inaccurate processing, expansion capabilities and resistance Strong failure capability and the effect of improving the working rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

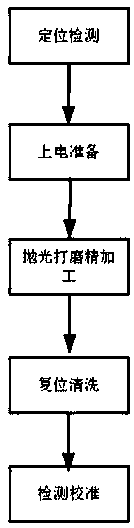

[0018] like figure 1 The integrated process of iron ball rocker arm processing and quality inspection includes the following steps:

[0019] The first step is positioning detection. First, ensure that the overall system is running without problems, the electrical signal connection is reliable, and there is no short circuit or signal interference. Second, ensure that the iron ball rocker arm and processing equipment can be used normally, and that the processing equipment can control the iron ball. The rocker arm is ready for positioning;

[0020] The second step is to prepare for power-on, power on the whole system, and power on other parts through the switch and the operation port. Casting work to make sure the bearings, sliding gears and drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com