An automatic feeding device

A technology of automatic feeding and feeding, which is applied in the directions of transportation and packaging, conveyor objects, etc., which can solve the problems of inability to perform alarm reminders, no way to detect, and inability to ensure the consistency of the feeding place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

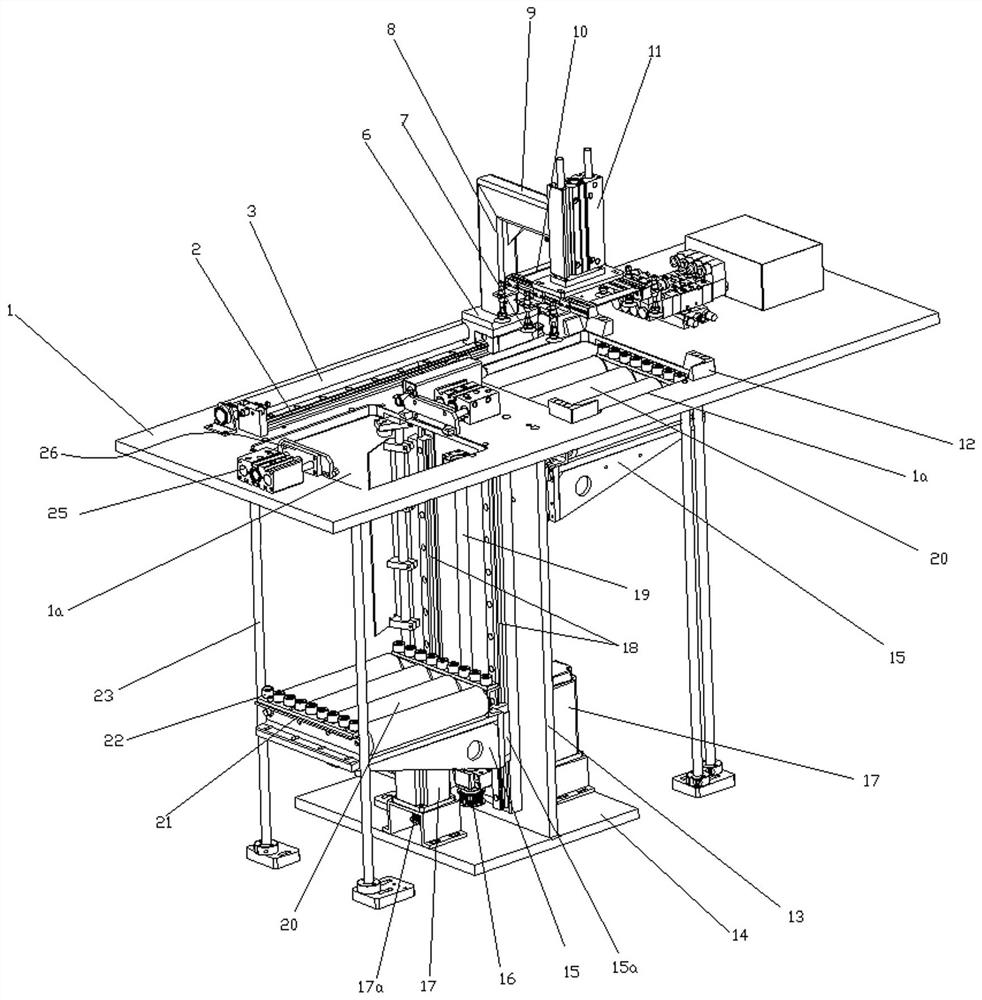

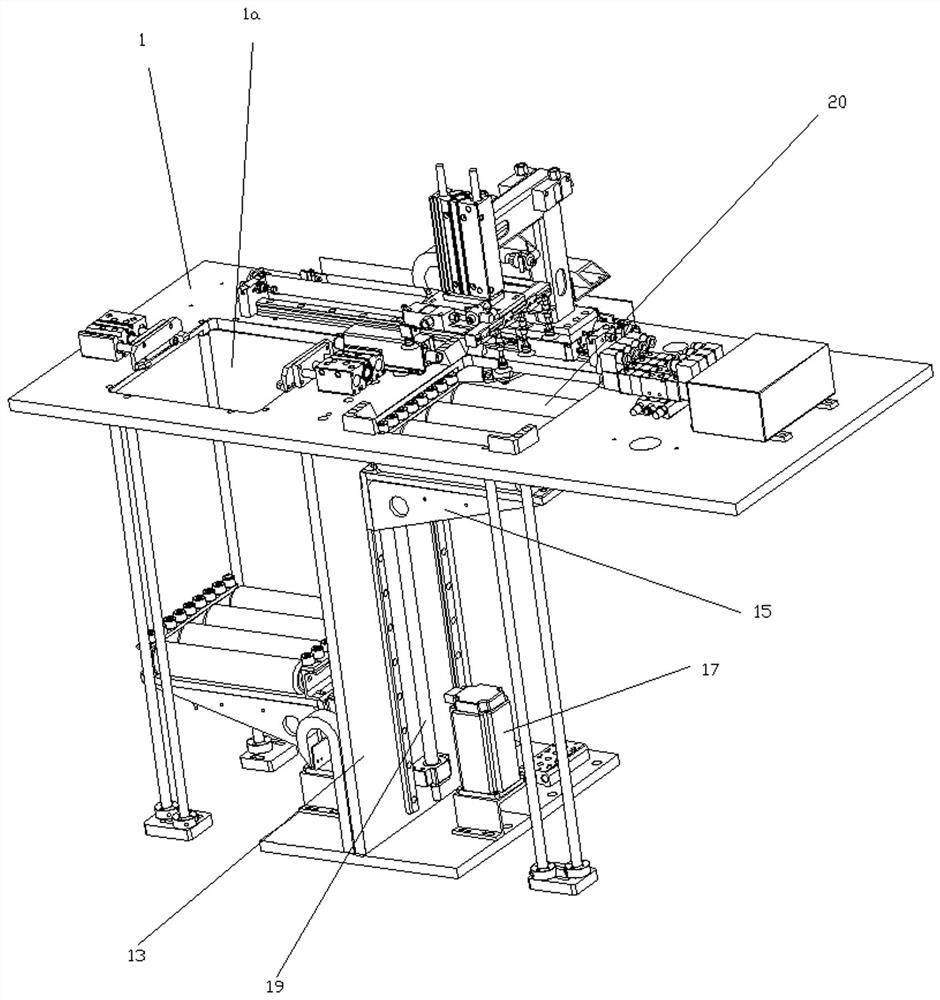

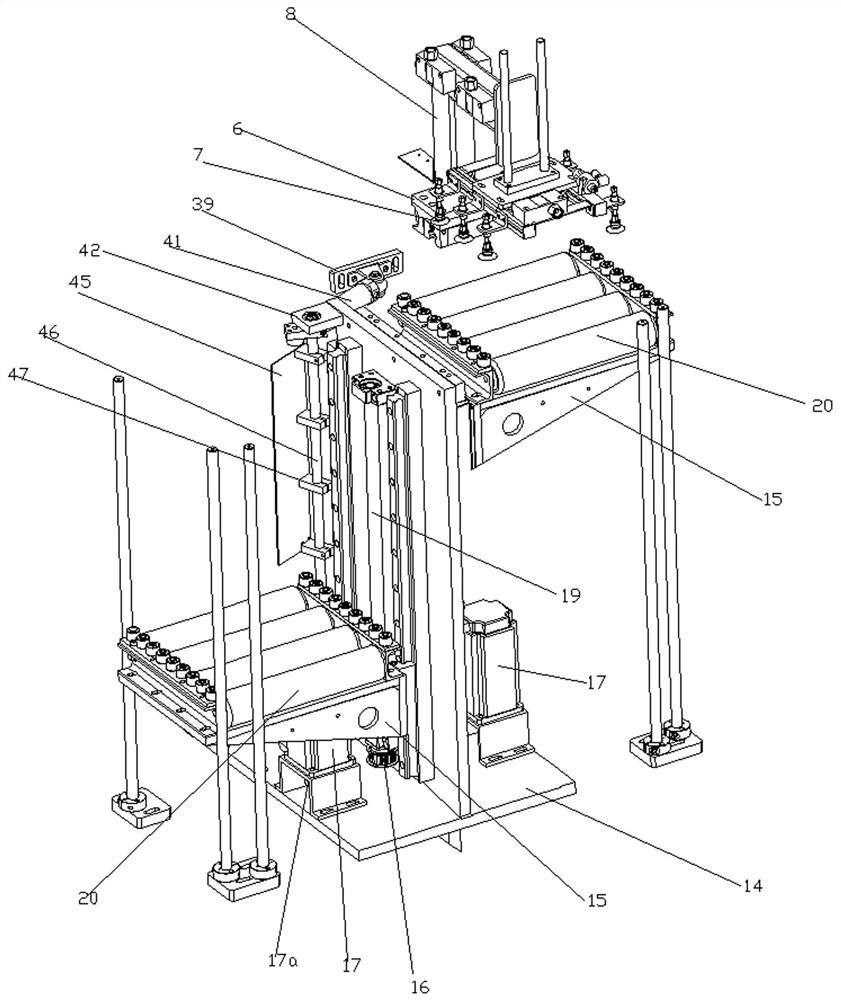

[0024] A kind of automatic feeding device provided by the invention, such as figure 1 So, comprise the basic structure in the prior art: base 14, the riser 13 that is connected on the base, the workbench 1 that is connected on the riser top, the periphery below the workbench is provided with support bar 23, the innovative structure of the present invention includes The following sections:

[0025] a. The tray loading device and the tray recovery device have the same structure and are symmetrically arranged on the facades on both sides of the vertical plate 13;

[0026] Taking the tray feeding device as an example, it is arranged on the facade on the left side of the vertical plate 13, and includes a rotatable vertical lead screw 19 connected respectively, and two vertical guide rails 18 are located on both sides of the lead screw 19. , a roller support 15 that moves up and down along the guide rail 18 is arranged on the facade, end plates 21 are respectively provided at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com