A non-contact monitoring system and monitoring method for offshore fan blade faults

An offshore wind turbine, non-contact technology, applied in the monitoring of wind turbines, wind turbines, motors, etc., can solve the problems of increasing the difficulty of blade manufacturing, high maintenance costs, reducing blade strength, etc., to facilitate on-site maintenance, correct interference, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

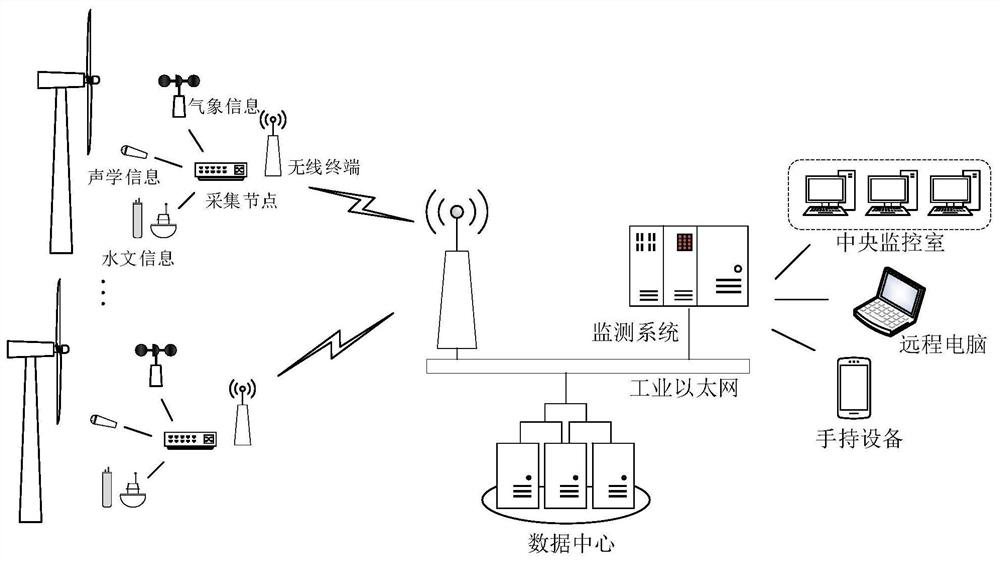

[0026] Example 1, such as figure 1 As shown, this embodiment discloses a non-contact monitoring system for faults of offshore wind turbine blades. The system includes a meteorological information collection system arranged on the offshore wind turbine foundation, tower foundation or a separate platform, and The hydrological information collection system, the aeroacoustic collection system arranged on the foundation or tower of the offshore wind turbine, the data collected by the meteorological information collection system, the hydrological information collection system and the aeroacoustic collection system are transmitted to the collection node in real time, and then the collection node passes wireless The terminal is transmitted to the onshore data center, and the data center, monitoring system and monitoring equipment are connected and communicated through industrial Ethernet.

[0027] In this embodiment, the number of offshore wind turbines is more than two, and each offs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com