Application of flexible high-pressure bag body system with uniform stress

A uniform stress and system application technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of narrow application surface, etc., to reduce flange displacement, strong compressive and tensile deformation performance, The effect of strengthening the compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

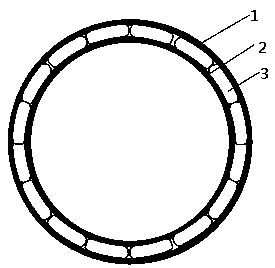

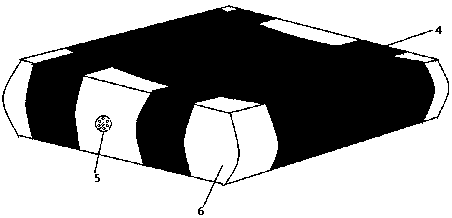

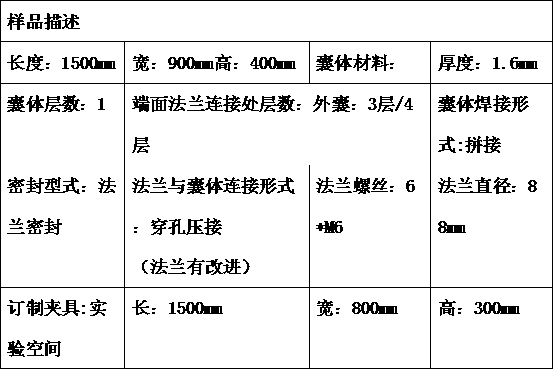

[0024] 1) Immerse the aramid fiber material in the solution of silane coupling agent and dry it. Coat the dried material with a polyurethane solution prepared with ethyl acetate on one side and dry it. The length is 1500mm, the width is 900mm, the height is 400mm, and the thickness is 1.6mm. The size is woven with processed aramid fiber as a whole. The coated side is on the outer layer, and a circular air hole is reserved at the top to obtain the inner capsule; 2) 1. Use sealing and fastening flanges with two or more compression grooves for fastening, and the outer flange and the compression flange are compressed and fixed at the circular air hole to form a sealing joint structure that prevents the flange from being pulled out; the sealing is tight The diameter of the solid flange is 88mm; 3) A high-strength fiber composite material is prepared by compounding aramid fiber with ultra-high molecular weight polyethylene, and the overall weaving is carried out according to the desi...

Embodiment 2

[0026] 1) Immerse the aramid fiber material in the solution of silane coupling agent and dry it. Coat the dried material on one side with a rubber solution prepared with dimethyl sulfoxide and dry it. The length of the capsule is 1500mm, the width is 900mm, the height is 400mm, and the thickness is 2.0mm. The size of the treated aramid fiber is woven as a whole. The coated side is on the outer layer, and a circular air hole is reserved at the top to obtain the inner capsule; 2) The sealing and fastening flanges respectively containing more than two compression grooves are used for fastening, and the outer flange and the compression flange are compressed and fixed at the circular air hole to form a sealing joint structure that resists pull-off of the flange; The diameter of the sealing and fastening flange is 88 mm; 3) A high-strength fiber composite material is prepared by compounding aramid fiber with ultra-high molecular weight polyethylene, and the overall weaving is carried...

Embodiment 3

[0028] 1) Immerse the aramid fiber material in the solution of silane coupling agent and dry it, and coat the dried material on one side with a rubber solution prepared with N,N-dimethylacetamide, and carry out Drying, according to the length of the capsule body is 1500mm, the width is 900mm, the height is 400mm, and the thickness is 2.0mm, it is woven with the treated aramid fiber as a whole, the coated side is in the outer layer, and a circular air hole is reserved at the top to obtain Inner capsule; 2) Use sealing and fastening flanges with more than two compression grooves for fastening, and the outer flange and the compression flange are compressed and fixed at the circular air hole to form a pull-out resistance of the flange The sealing joint structure; the diameter of the sealing and fastening flange is 88mm; 3) A high-strength fiber composite material is prepared by compounding aramid fiber with ultra-high molecular weight polyethylene, and the overall weaving is carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com