A stress-strain prediction method based on machine learning

A stress-strain and machine learning technology, applied in the field of detection and prediction, can solve problems such as the indetermination of the strain function model, achieve the effects of convenient operation, easy promotion, and improved calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

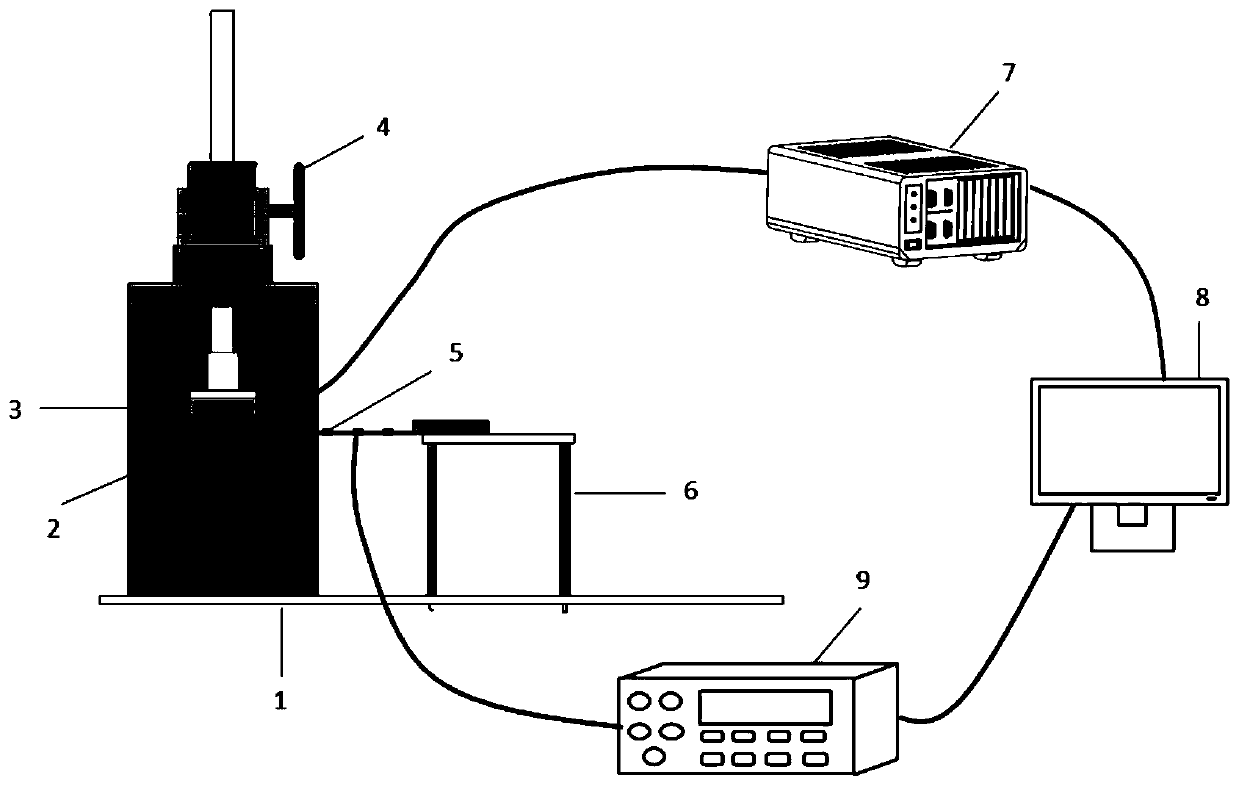

[0039] attached figure 1Installation diagram for the strain sensor prediction system. The model of the optical fiber demodulator used in this example is si255-16-ST / 160-NO of MOI Company, its measuring range is -15000—15000με, the demodulation accuracy is 1pm, its measuring range is 0—2000με, the resolution is 0.5με. The data acquisition system selects the virtual instrument-based controller combination produced by American NI Company. Including data acquisition module NI PCI-4461, input and output module NI PCI-6528 / 5922, controller host PXIe-1082DC. Among them, the resolution of the data acquisition module PCI-4461 reaches 24 bits, and the sampling rate can reach 204.8kS / s. The force sensor is a model 41 load cell of Honeywell Company, which has a low error rate of up to 0.1%, and an optional output of 0 to 5V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com