Permanent magnet rotor assembly and motor

A technology for permanent magnet rotors and components, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of weak combination of magnetic block and permanent magnet, low production efficiency, poor injection quality, etc. Achieve the effects of not easy to deform, high production efficiency and good injection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

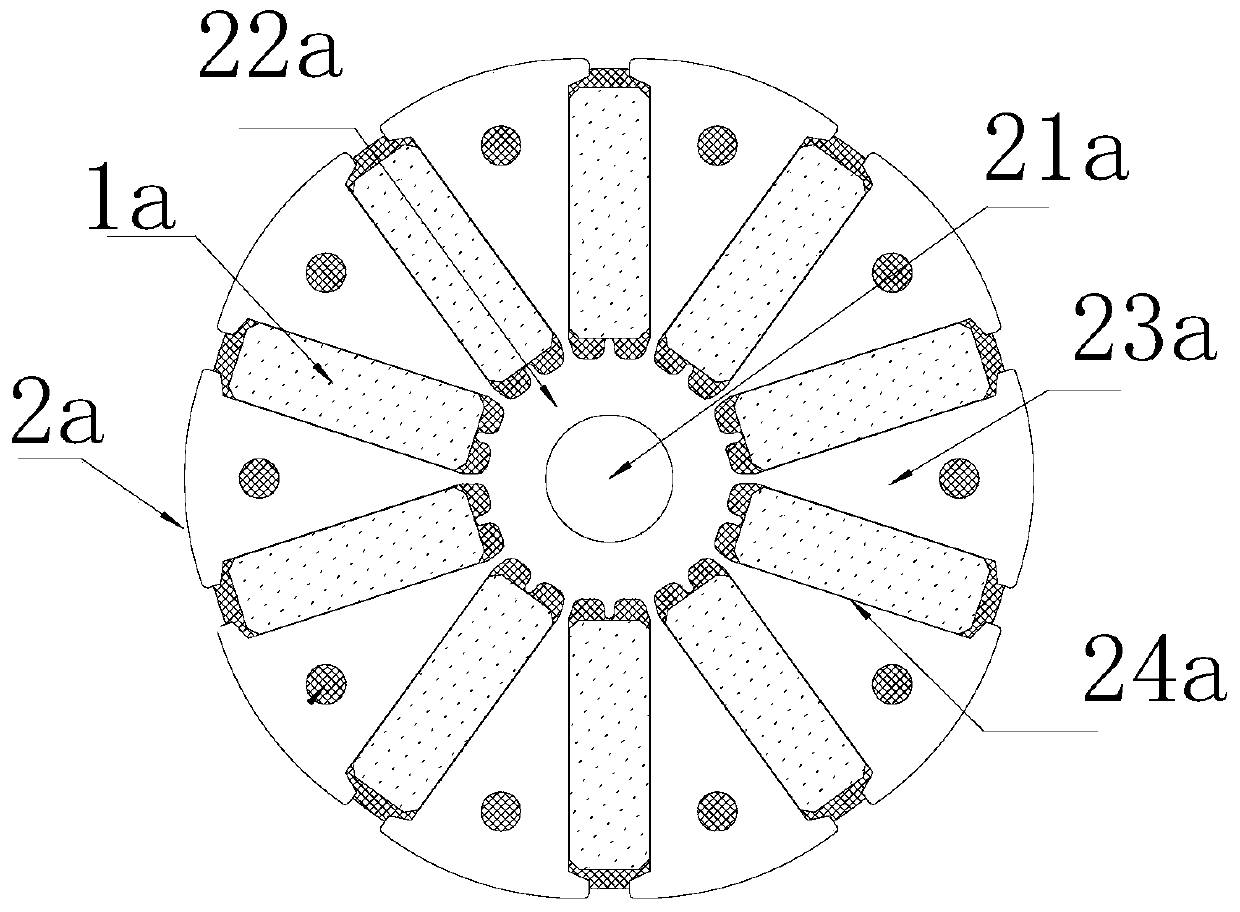

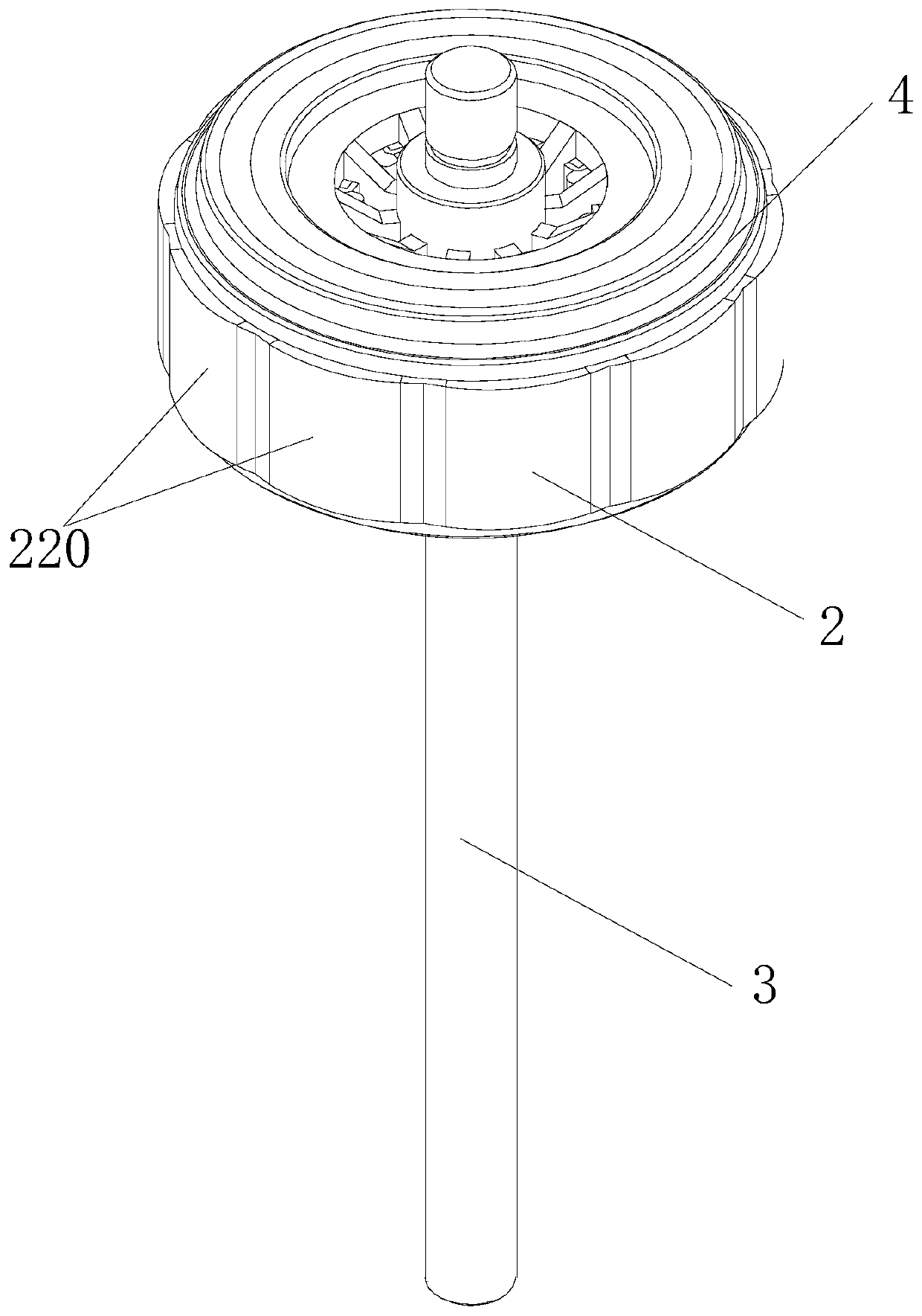

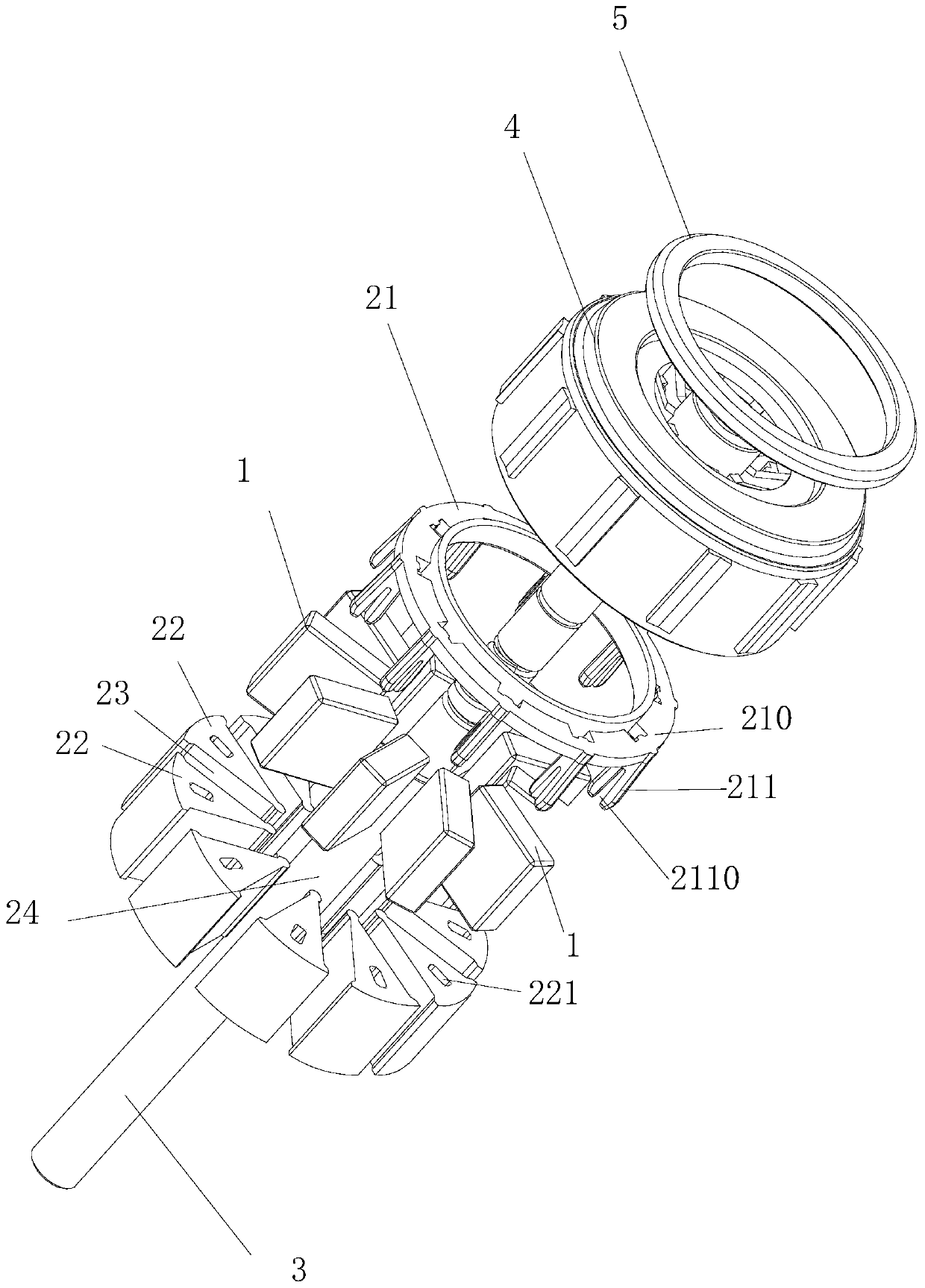

[0030] Example 1: as Figure 2 to Figure 9 As shown, the present invention is a permanent magnet rotor assembly, including a plurality of permanent magnets 1, a rotor iron core assembly 2, a rotating shaft 3 and a plastic sealing body 4, and the rotor iron core assembly 2 includes a mounting bracket 21 and a number of magnetic conductive blocks 22, so The above-mentioned mounting bracket 21 includes an annular end plate 210 and a plurality of clamping blocks 211 axially protruding from one end face of the annular end plate 210. The plurality of clamping blocks 211 are distributed around the annular end plate 210 at intervals. , a plurality of magnetic conductive blocks 22 are installed through the cooperation of the clamping block 211 and the card slot 221 to form a central hole 24, a radial groove 23 is formed between two adjacent magnetic conductive blocks 22, and the permanent magnet 1 is nested in the radial groove. Inside the groove 23 , the rotating shaft 3 passes throug...

Embodiment 2

[0038] This embodiment provides a motor, which includes a stator assembly, a permanent magnet rotor assembly and a motor housing, and is characterized in that: the permanent magnet rotor assembly is the permanent magnet rotor assembly described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com