A dual-stator field-modulated permanent magnet motor suitable for electric tractors

A magnetic field modulation and permanent magnet motor technology, which is applied in the direction of electromechanical devices, electrical components, magnetic circuit rotating parts, etc., can solve the problems of increasing the difficulty of motor processing and manufacturing, low power factor of the vernier motor, and increasing the torque density of the motor. Achieve the effects of increasing the winding space and the corresponding electrical load capacity, increasing the utilization rate of the permanent magnet, and improving the output torque and power factor of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

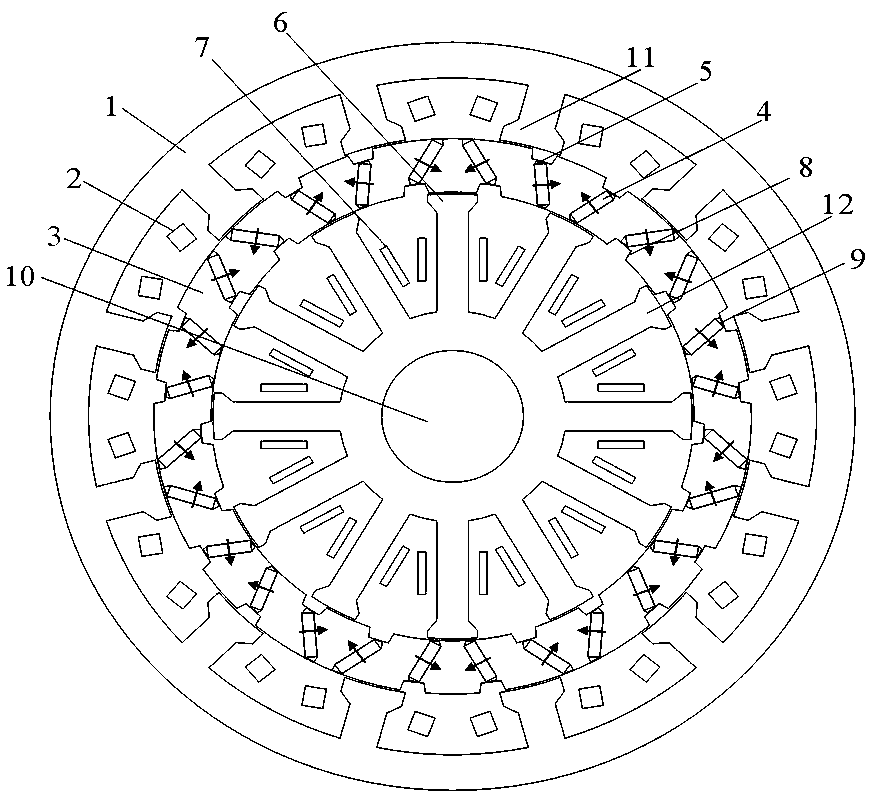

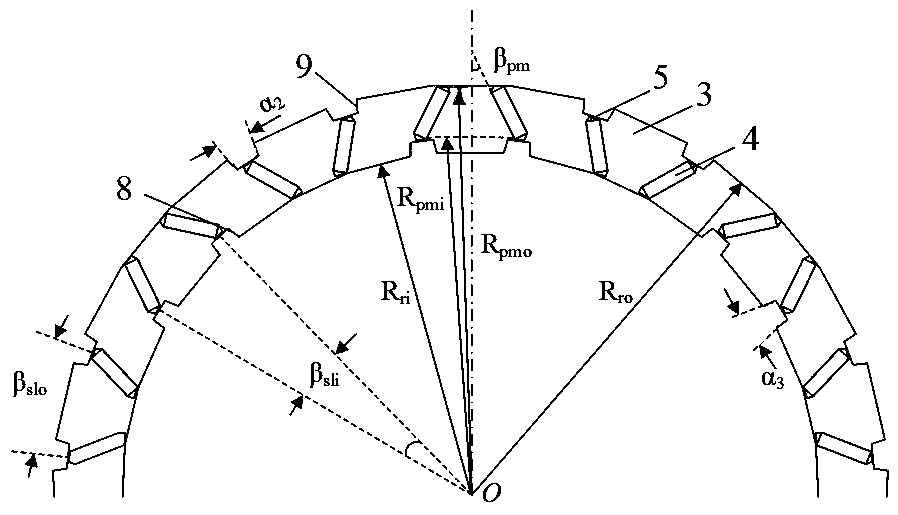

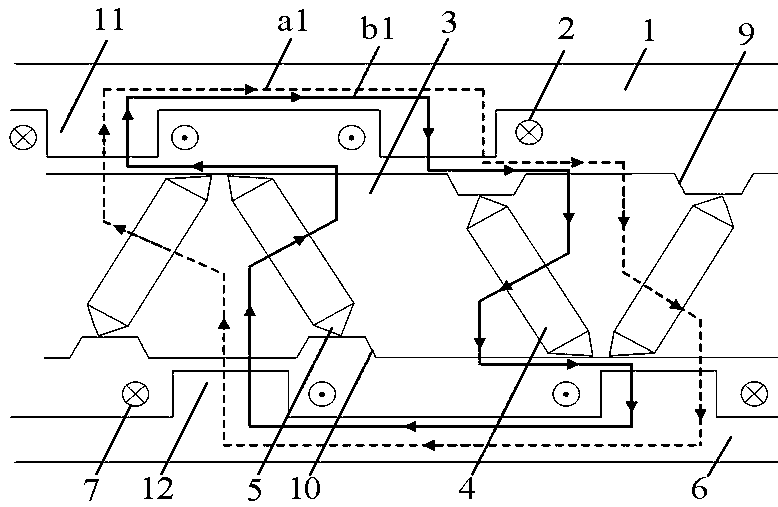

[0025] see figure 1 , the present invention is composed of an outer stator 1, an intermediate rotor 3, an inner stator 6, an outer armature winding 2, an inner armature winding 7 and a nonmagnetic rotating shaft 10. The outer stator 1 is coaxially sleeved outside the intermediate rotor 3 , the intermediate rotor 3 is coaxially sleeved outside the inner stator 6 , and the inner stator 6 is coaxially sleeved outside the non-magnetic rotating shaft 10 . In this way, in the radial direction, from inside to outside in the present invention, the non-magnetically conductive rotating shaft 10, the inner stator 6, the intermediate rotor 3, and the outer stator 1 are coaxially fitted. The outer stator 1 is composed of the outer stator yoke and the salient poles 11 of the outer stator core, and the inner stator 6 is composed of the inner stator yoke and the salient poles 12 of the inner stator core. The outer armature winding 2 is wound on the salient pole 11 of the outer stator core, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com