Method for making yoghurt by ohmic heating

A technology of ohmic heating and yogurt, which is applied in the field of yogurt production, can solve the problems of affecting the taste and flavor of the final product, affecting the product tissue state, and changing the texture of yogurt, so as to improve product sensory evaluation, avoid local excessive heating, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

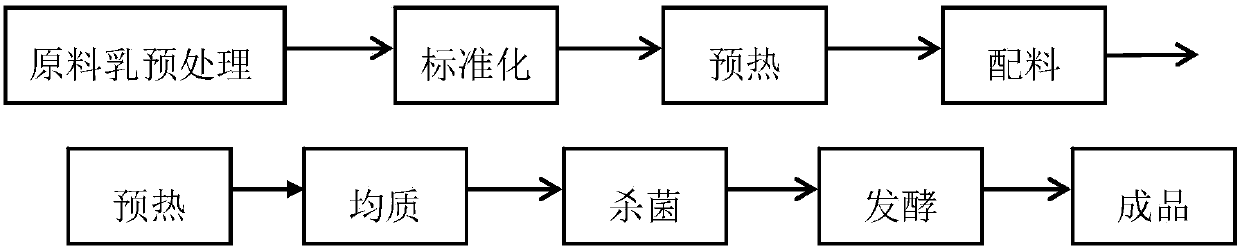

Method used

Image

Examples

Embodiment 1

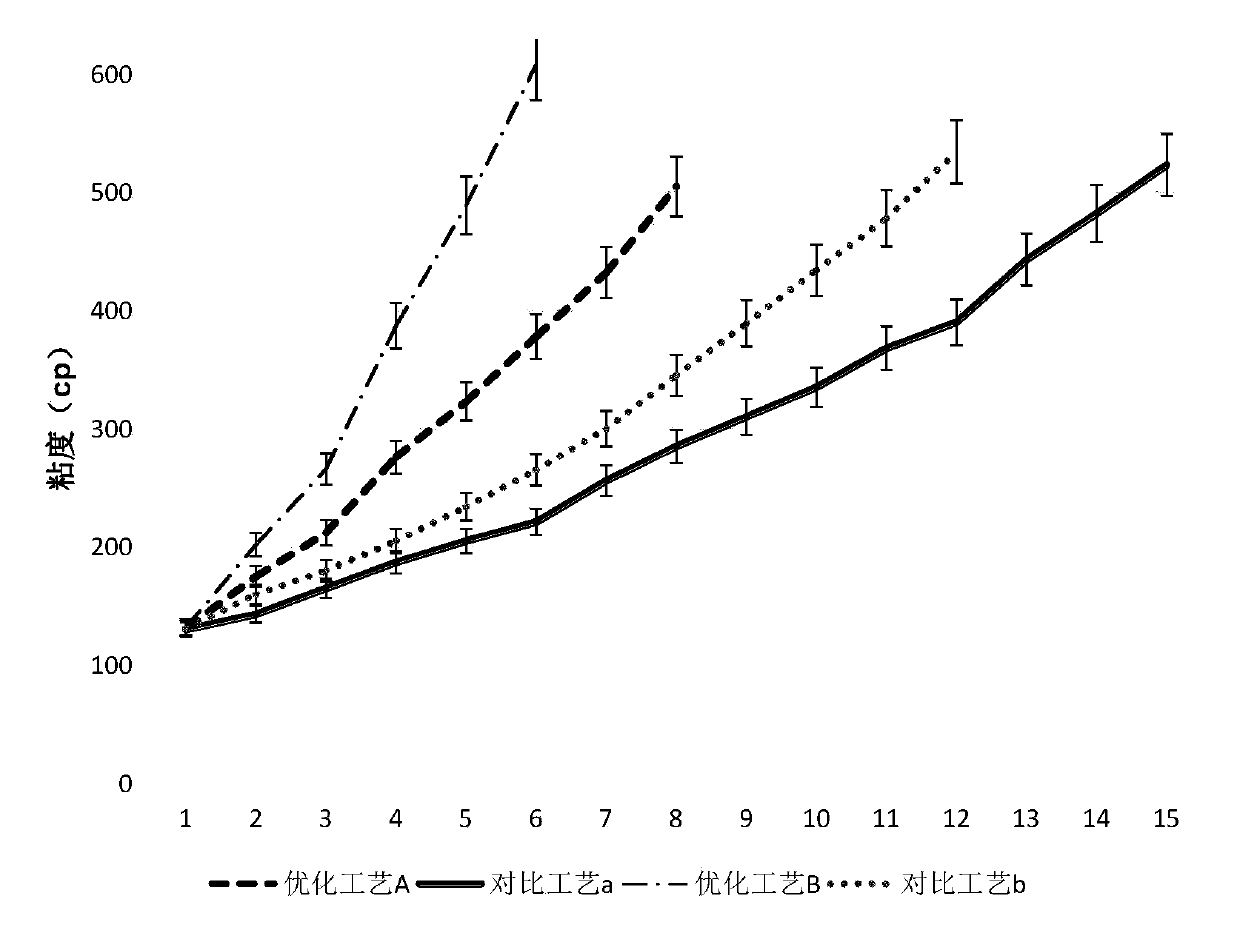

[0026] First, the stabilizer, such as modified starch, is dissolved and dispersed under the existing technical parameters, and then different heat treatments are performed. Due to the difference in the degree of heating of the material during the production of yogurt, the degree of dissolution and expansion of the stabilizer (modified starch) in the material is inconsistent, resulting in the inability of the stabilizer to fully function or causing the stabilizer to be overheated and lose stability.

[0027] The same stirring rate is used in the preheating and heating process of the yogurt material to reduce the influence of the stirring speed of the material on the heating of the yogurt material, and to simulate the conditions when the yogurt material is conveyed in the heater in actual production, so that the influence of the heating method dominates.

[0028] After comparing with the yoghurt heating process to reach the preset viscosity value, the heating temperature, heating...

Embodiment 2

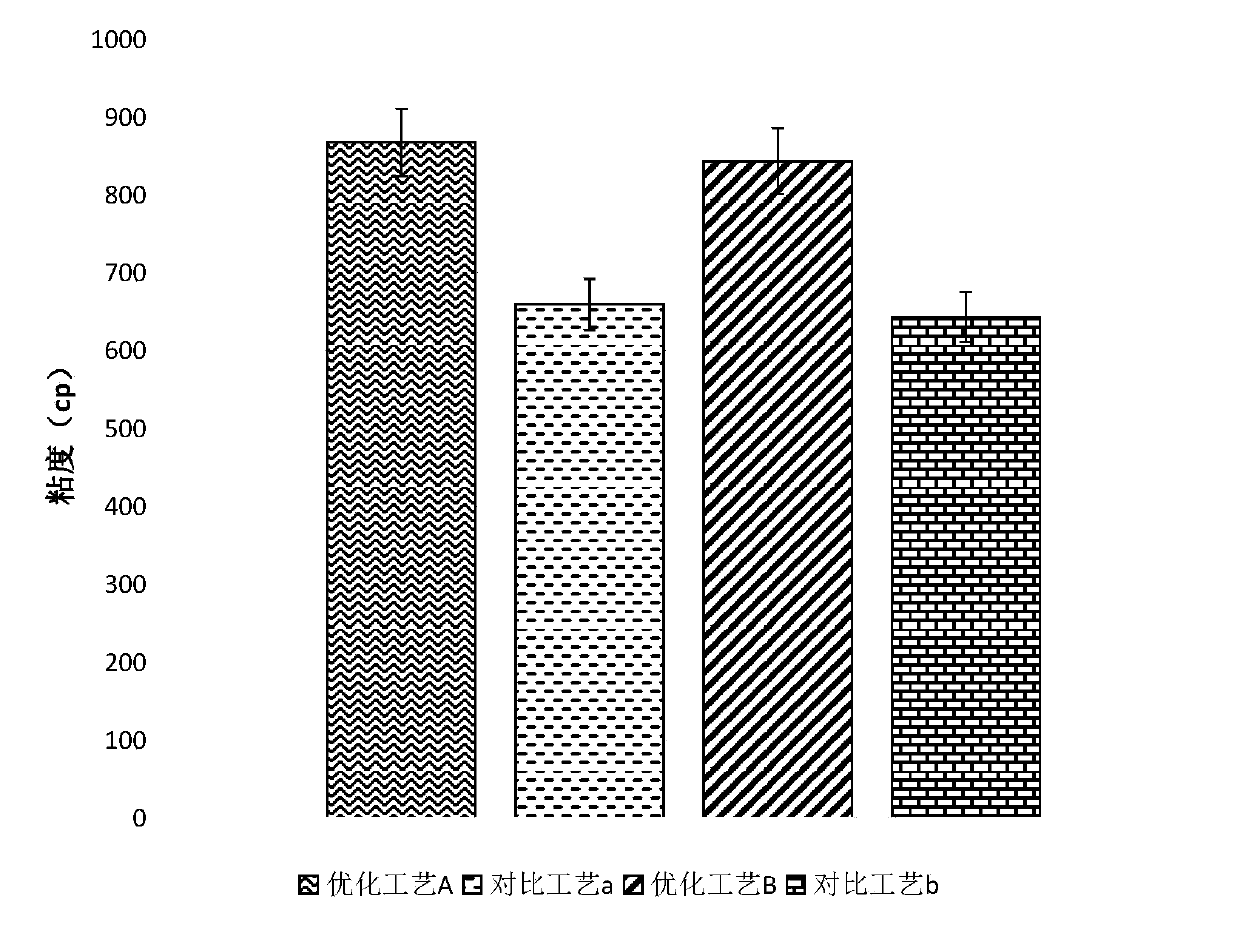

[0053] First, protein powder materials, such as whey protein powder, are dissolved and dispersed under the existing technical parameters, and then different heat treatments are performed. Due to the difference in the degree of heating of the materials during the production of yogurt, the degree of water absorption and swelling of the protein powder material (whey protein powder) in the material is inconsistent, resulting in the inability of the material to fully function and affecting the final sensory evaluation of the product.

[0054] The same stirring rate is used in the preheating and heating process of the yogurt material to reduce the influence of the stirring speed of the material on the heating of the yogurt material, and to simulate the conditions when the yogurt material is conveyed in the heater in actual production, so that the influence of the heating method dominates.

[0055] After comparing the heating temperature, heating time, and product sensory evaluation a...

Embodiment 3

[0064] It is used in the preheating stage of yogurt processing to avoid local overheating by heat conduction and improve heating efficiency at the same time.

[0065] After the material is treated under the same conditions, it is compared with different heating treatments. Due to the different heating methods, the heating surface of the material during the transportation process is inconsistent, resulting in different heating degrees of the material, which affects the heating efficiency of the final material.

[0066] The same conveying rate and the same initial temperature are used in the preheating and heating process of the yogurt material to reduce the influence of the conveying speed and temperature of the material on the heating efficiency of the yogurt material, and to simulate the conditions when the yogurt material is conveyed in the heater in actual production , so that the effect of the heating method dominates.

[0067] After comparing the time required to reach th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com