Raw material crusher for firecracker preparation

A pulverizer and raw material technology, applied in the direction of grain processing, etc., can solve the problems of troublesome production of firecrackers and difficulty in crushing, and achieve the effects of reducing working pressure, ensuring thorough chopping, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

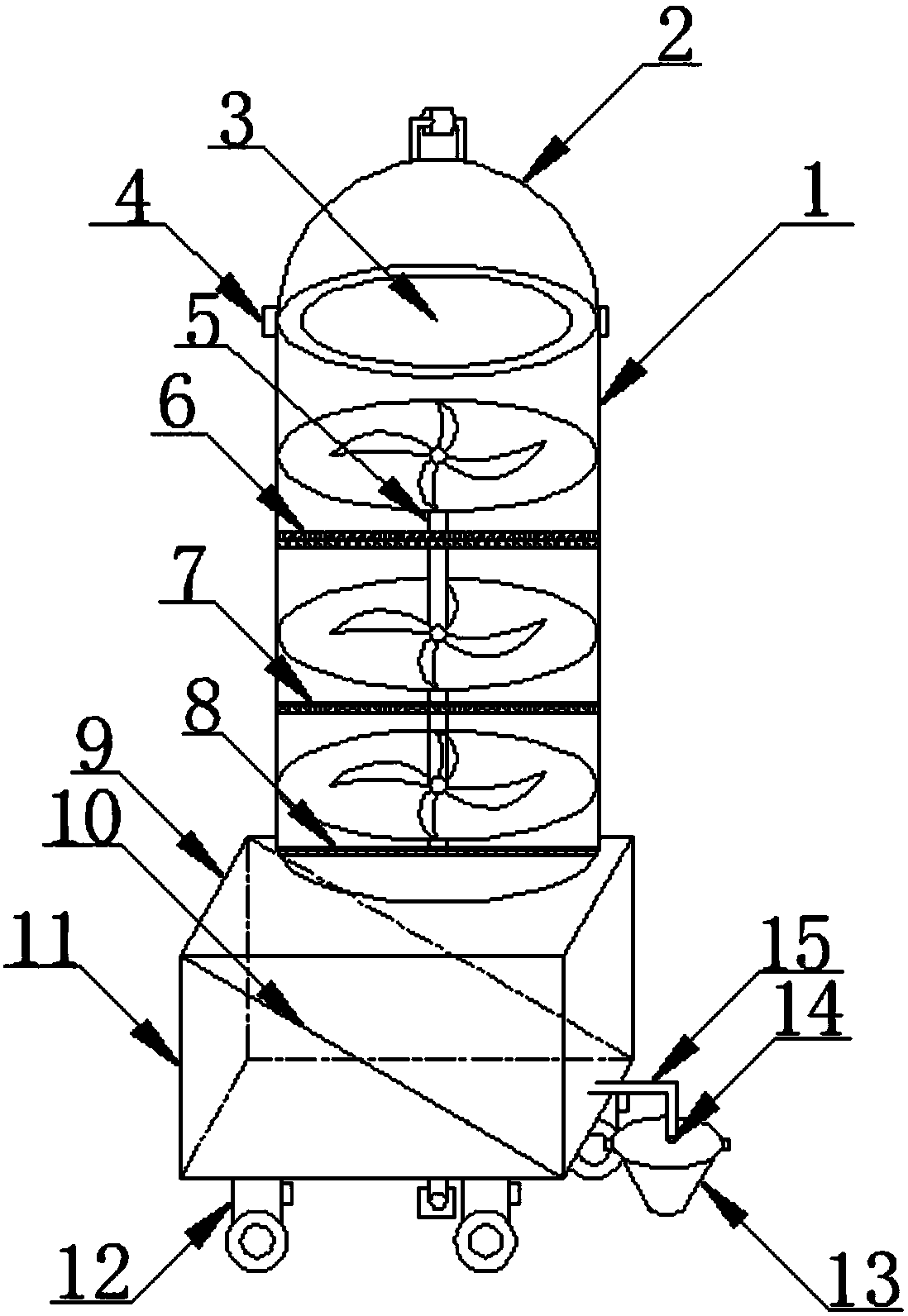

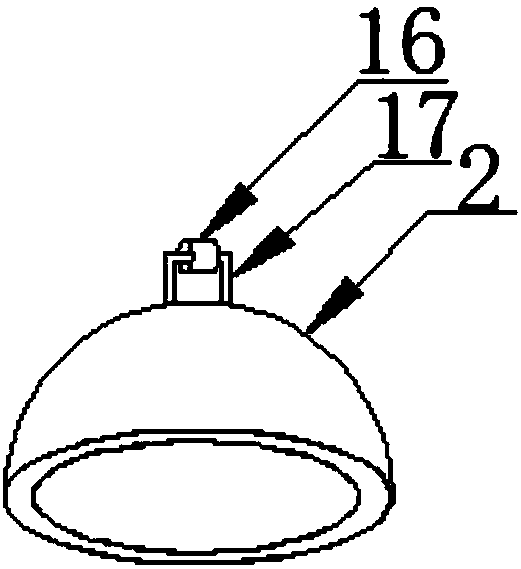

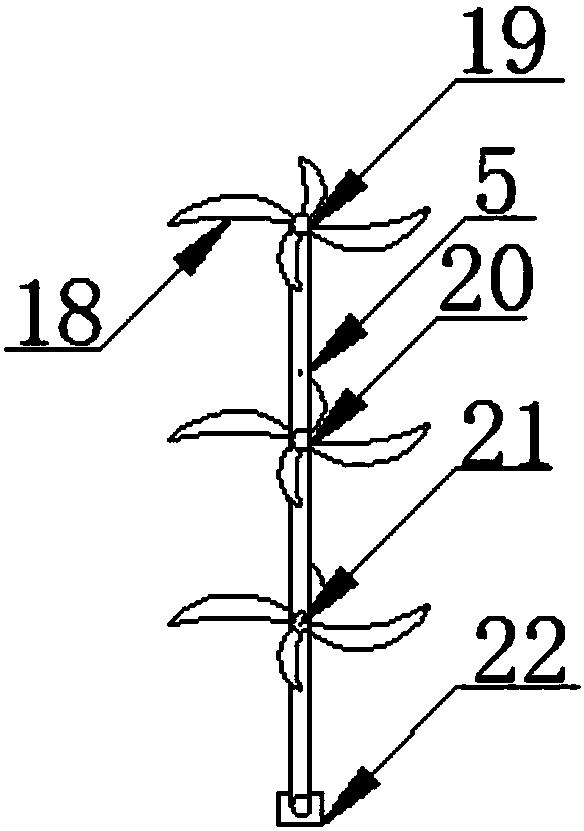

[0019] see Figure 1-4 , the present invention provides a technical solution: a raw material grinder for making firecrackers, including a barrel body 1, a barrel cover 2, a firecracker raw material inlet 3, a fixed buckle 4, a rotating shaft 5, a first filter 6, a second filter Net 7, third filter net 8, discharge chamber 9, discharge slide plate 10, wedge-shaped block 11, support shaft 12, accumulation barrel 13, discharge pipe socket 14, discharge pipe 15, anti-slip rubber sleeve 16, handle 17 , blade 18, the first cutting group 19, the second cutting group 20, the third cutting group 21, motor 22, universal wheel 23 and fixed switch 24, the upper end of the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com