Catalyst for synthesizing cyclic carbonate, preparation method of catalyst and preparation method of cyclic carbonate

A cyclic carbonate and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

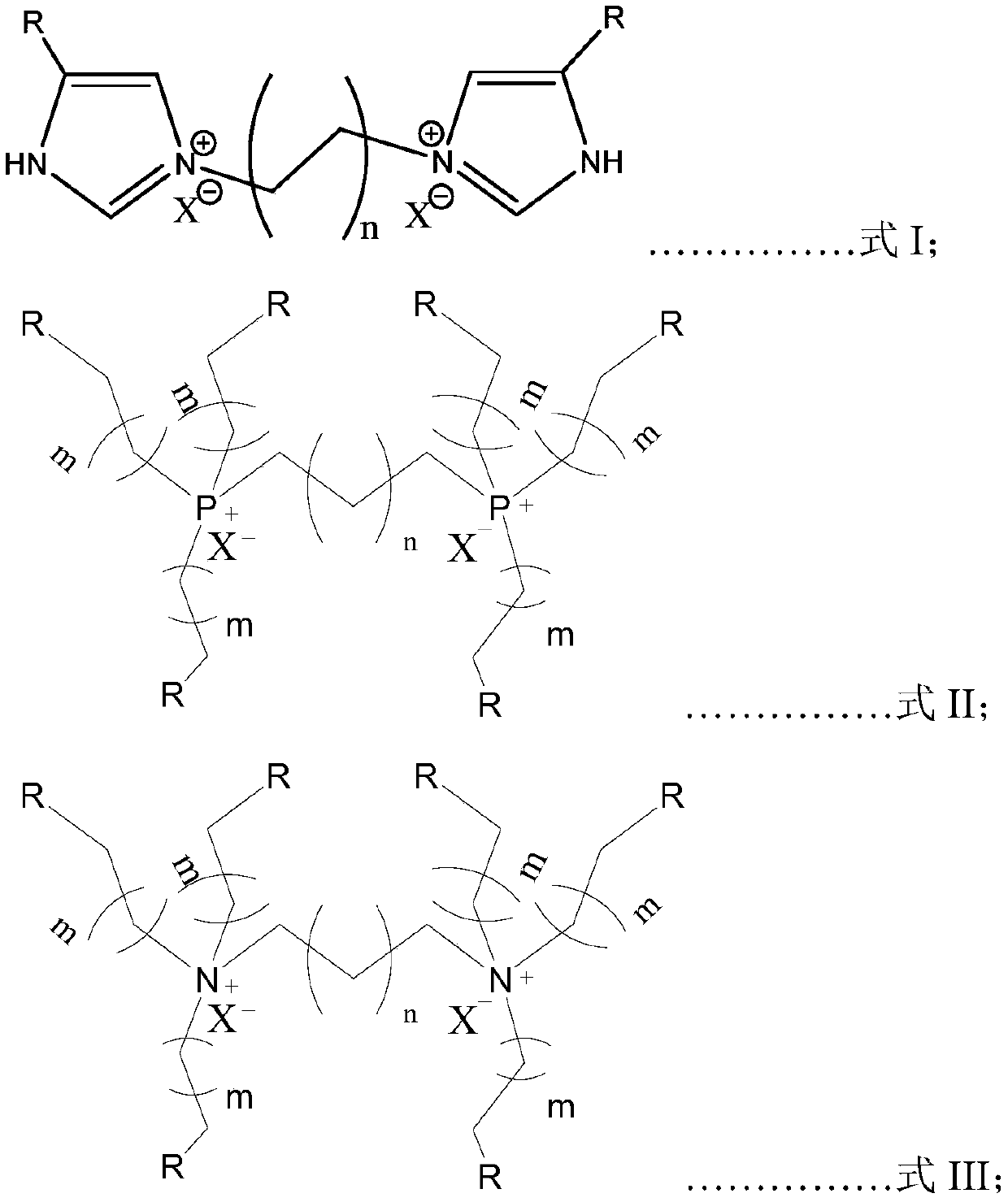

[0046] In this embodiment, a catalyst is prepared by the following method, and the structure is as follows:

[0047]

[0048] In a 250mL three-necked flask equipped with a reflux device, dissolve 0.008mol of 1H-imidazole-4-carboxylic acid and 0.5mL of hydrochloric acid (36%-38%) in 100g of water together, and raise the temperature to 70℃ until the reactants are completely dissolved , Then add 0.004mol 1,2-dichloroethane dropwise, continue to stir, keep refluxing for 24h, until there is no more brown-yellow solid. After cooling, it was filtered under reduced pressure, washed with ethyl acetate, filtered and dried in vacuum for 24 hours to obtain a catalyst.

Embodiment 2

[0050] In this embodiment, a catalyst is prepared by the following method, and the structure is as follows:

[0051]

[0052] The preparation method refers to Example 1, only replacing 1,2-dichloroethane with 1,2-dibromoethane.

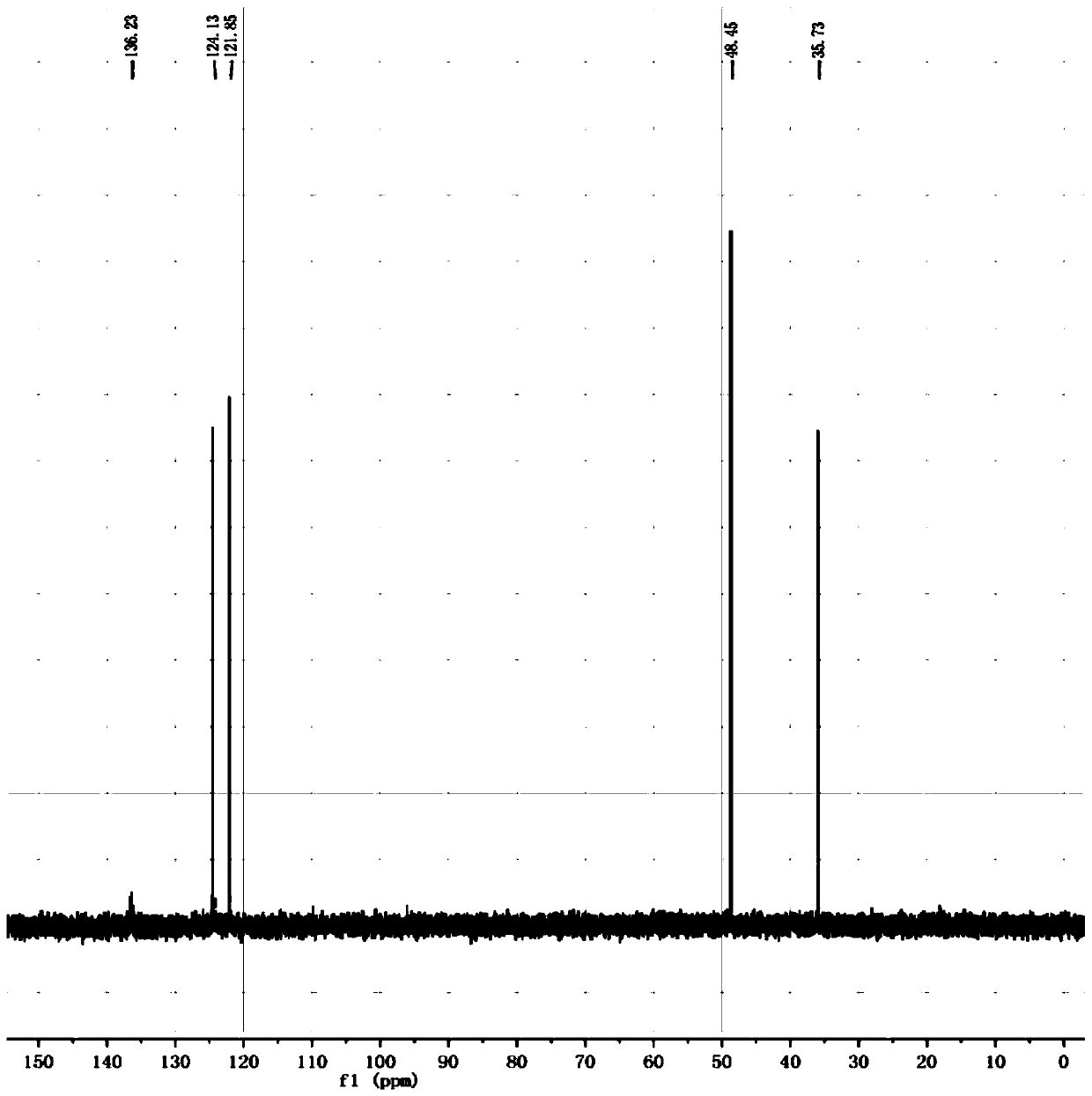

[0053] Carbon NMR spectrum: 13 C NMR(151MHz, D 2 O) δ136.30–136.16(m), 124.13(s), 121.85(s), 48.51–48.38(m), 35.73(s).

Embodiment 3

[0055] In this embodiment, a catalyst is prepared by the following method, and the structure is as follows:

[0056]

[0057] The preparation method refers to Example 1, only replacing 1,2-dichloroethane with 1,2-diiodoethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com