Silver-ion antibacterial rag

A silver ion antibacterial agent and silver ion technology, which is applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of antibacterial components falling into water, waste and resource consumption, and poor cleaning function of rags. Effect of fiber surface tension, reduction of static electricity, reduction of use cost and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

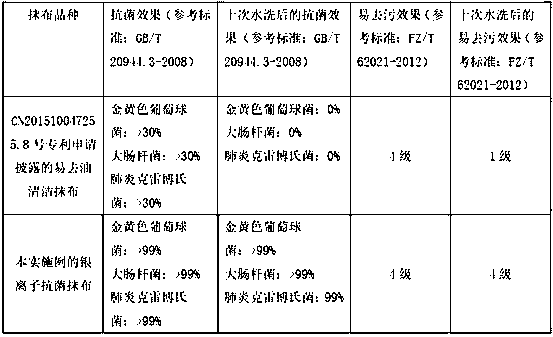

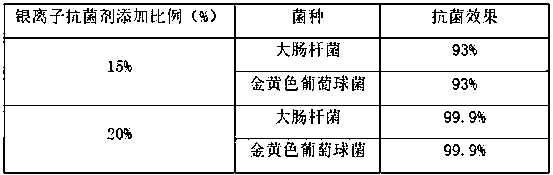

[0023] Example 1 Silver ion antibacterial spunlace nonwoven cloth

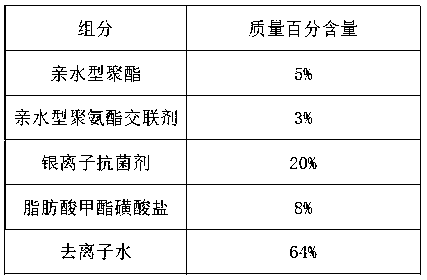

[0024] The silver ion antibacterial dishcloth of the present embodiment adopts non-woven fabric (fiber component: 100% viscose) as the base cloth. The base fabric has been treated with a treatment liquid. The mass percent concentration of the treatment solution is 12%, and the components of the treatment solution stock solution include: hydrophilic polyester (Shanghai Jiasen Technology Co., Ltd., model JS-1500), hydrophilic polyurethane crosslinking agent (Ningbodi Special Chemical Co., Ltd., model HGT), silver ion antibacterial agent (Shanghai Jiasen Technology Co., Ltd., model JS-2000), fatty acid methyl ester sulfonate (AkzoNobel Chemical, model 226SA) and deionized water. See Table 2 for the mass percentage of each component in the stock solution of the treatment solution (that is, the value accounting for the total mass of the stock solution of the treatment solution).

[0025] Table 2 The mass percenta...

Embodiment 2

[0037] Different from Example 1, the fiber component of the base cloth of the silver ion antibacterial wipes of this example is 60% viscose and 40% polyester. The mass percent content of each component in the rag treatment liquid stock solution is shown in Table 4.

[0038] Table 4 The mass percentage of each component in the treatment solution

[0039]

[0040] The specific manufacturing process of the dishcloth is as follows:

[0041] 1) Preparation of stock solution for rag treatment liquid: Put 70 kg of solid granular hydrophilic polyester into the reaction kettle, add 200 kg of deionized water, and then add 100 kg of hydrophilic polyurethane with a concentration of 40%, 100 kilograms of fatty acid methyl ester sulfonate, add 330 kilograms of deionized water, heat, increase the temperature by 2°C per minute, heat the water temperature to 85°C, keep high-shear stirring in the middle of the process, and stir at 85°C for 2 hours to obtain Uniform liquid, and finally add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com