A pipe jacking construction method with close-distance mud-water balance in sand ginger clay stratum

A construction method and mud-water balance technology, which can be used in earth-moving drilling, mining equipment, tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

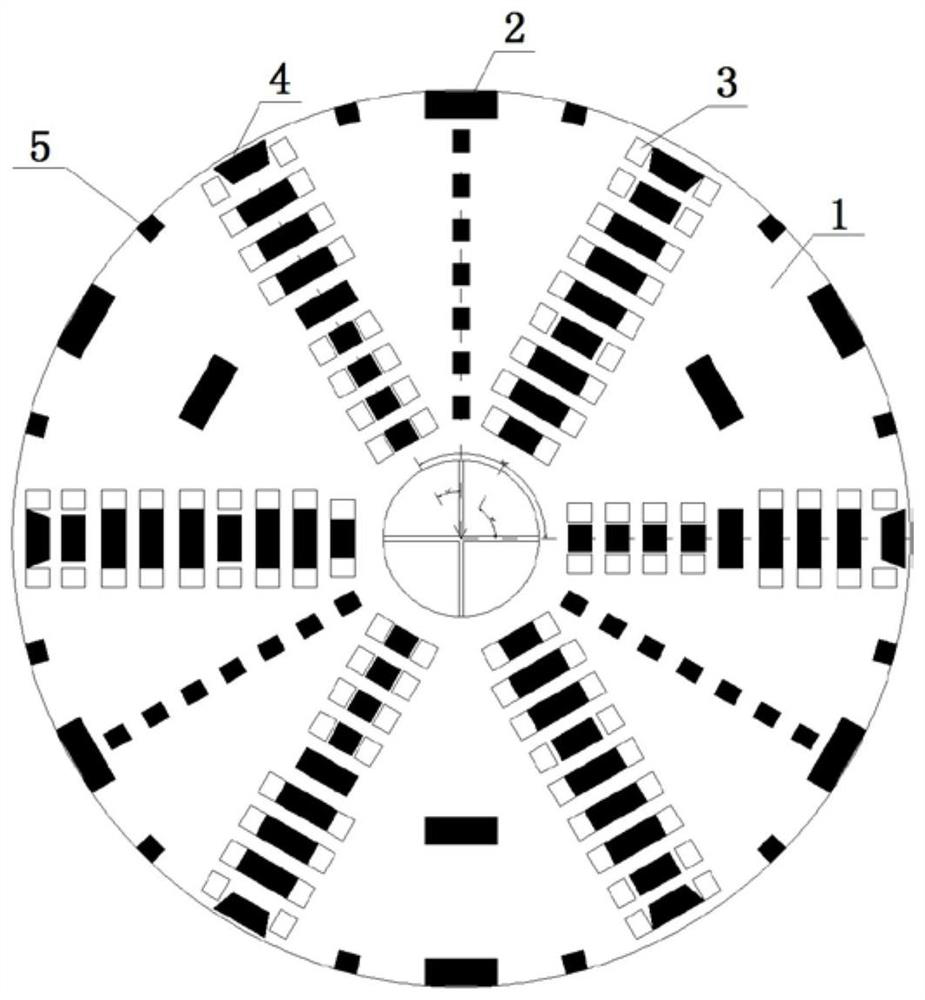

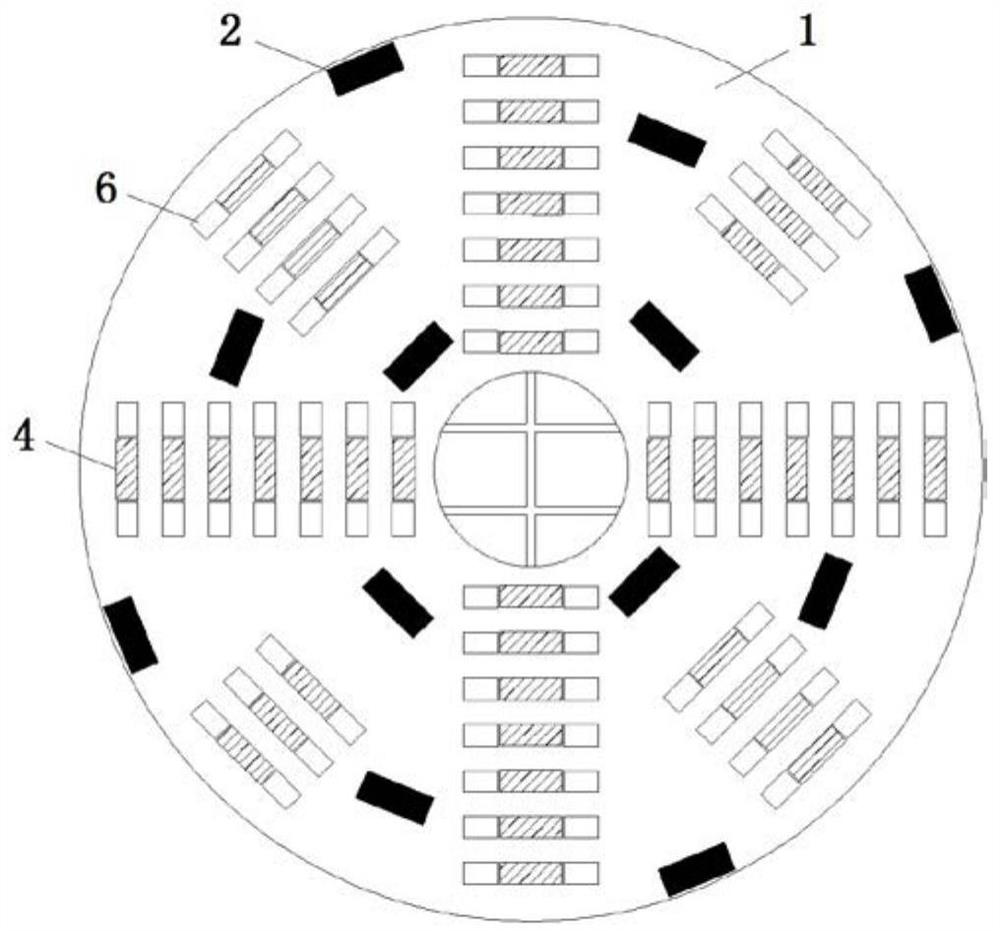

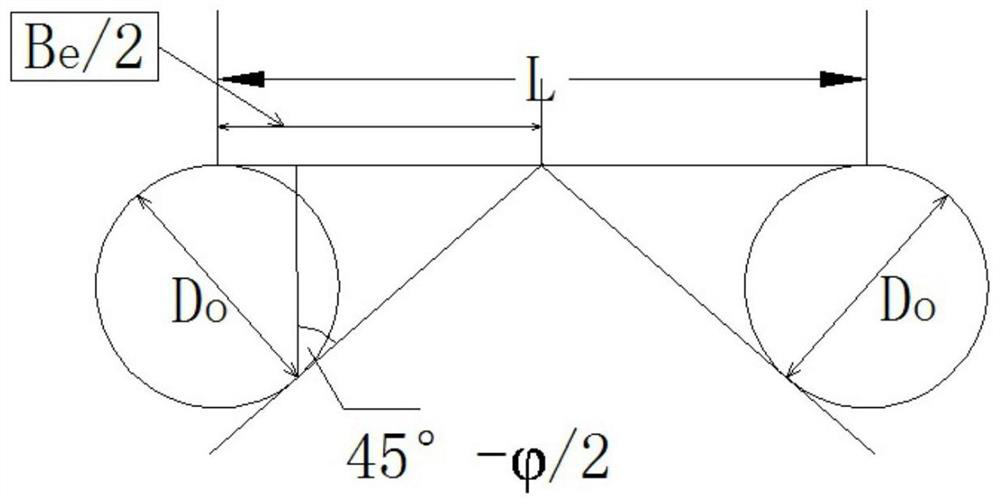

[0073] As shown in the figure, the present invention provides a construction method for near-distance mud-water balance pipe jacking in sand ginger clay stratum, and the construction method includes the following steps:

[0074] S1, Axis stakeout: Perform axis measurement and stakeout and retest the axis of the pipe jacking. The axis after the retest is qualified is used as the basis for the direction control of the pipe jacking. After qualified, proceed to the next step.

[0075] S2, installation of working well equipment: install the pipe jacking equipment in the well according to the axis measured and placed in step S1. The specific implementation is mainly divided into the following steps: the specific operation method of step S2 is:

[0076] S201, the installation of ground equipment, mainly the masonry of the on-site mud pool, the installation of mud-water separation equipment, the installation of slurry mixing equipment, the installation of hoisting equipment, the insta...

Embodiment 2

[0133] In this embodiment, taking the water source of Luoma Lake in Xuzhou City and the 06 bid section of the second surface water plant project as an example, the construction method of the present invention is used for construction. The water intake scale and the water delivery pipeline transportation scale are both 800,000 m 3 / d, the design uses double-row D2020 steel pipes. Among them, the section crossing the Xuhong River has a total length of 592m, and the buried depth of the pipeline is 4m to 17m. The pipeline is located in the sandy ginger clay layer, and the design adopts the pipe jacking construction technology. This section of pipe jacking has the characteristics of long jacking distance, complex geology, difficult jacking force control, and tight construction schedule, making construction difficult.

[0134] This soil layer is sand-containing ginger clay layer, and its main component is clay, but because it contains ginger stones, it has the characteristics of hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com