Three-dimensional scanning device

A technology of three-dimensional scanning and scanners, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high equipment operating costs, poor human comfort, high labor costs, etc., to reduce equipment costs, low cost, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

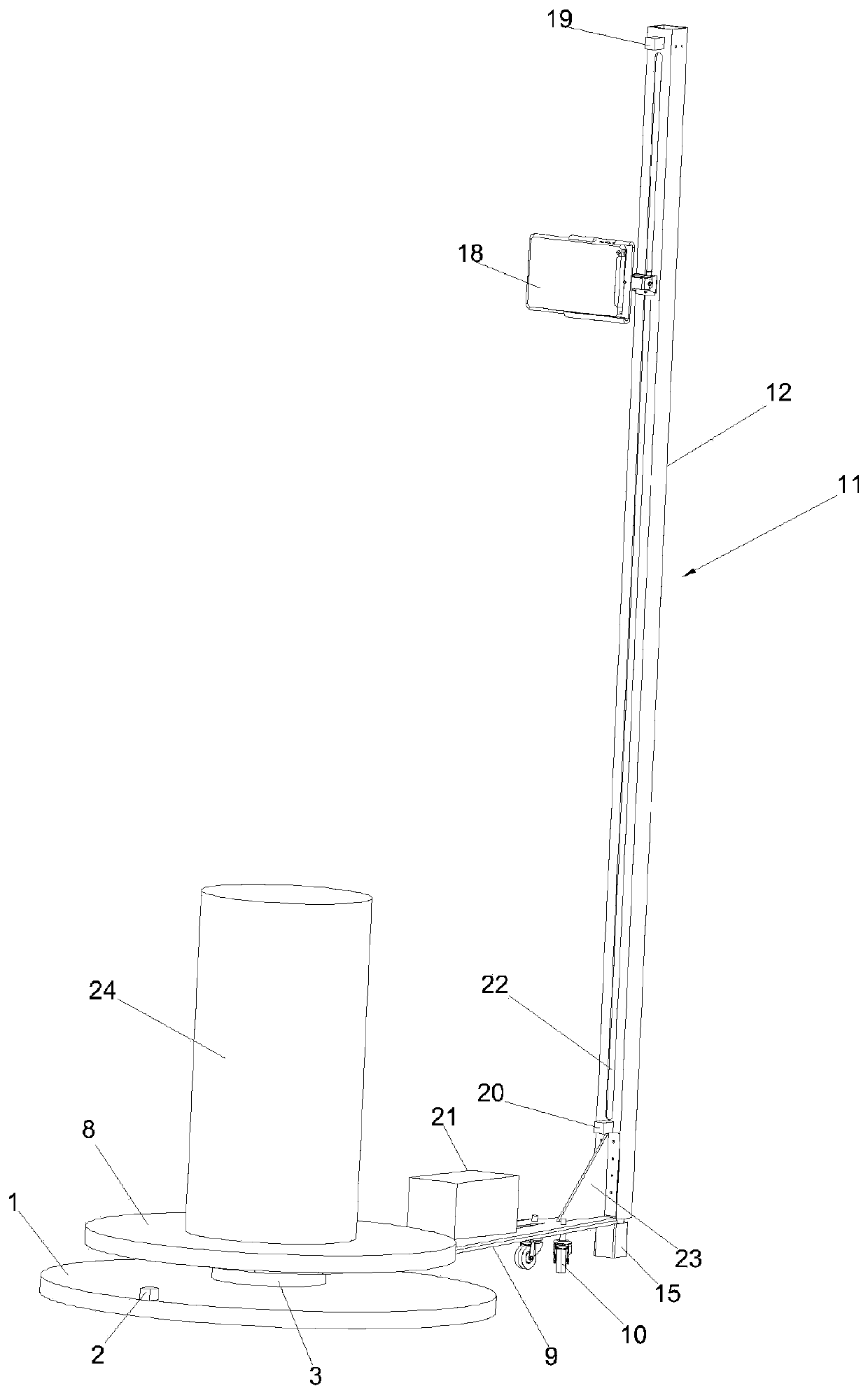

[0034] The working principle of the three-dimensional scanning device in this embodiment is as follows:

[0035] 1. Before scanning:

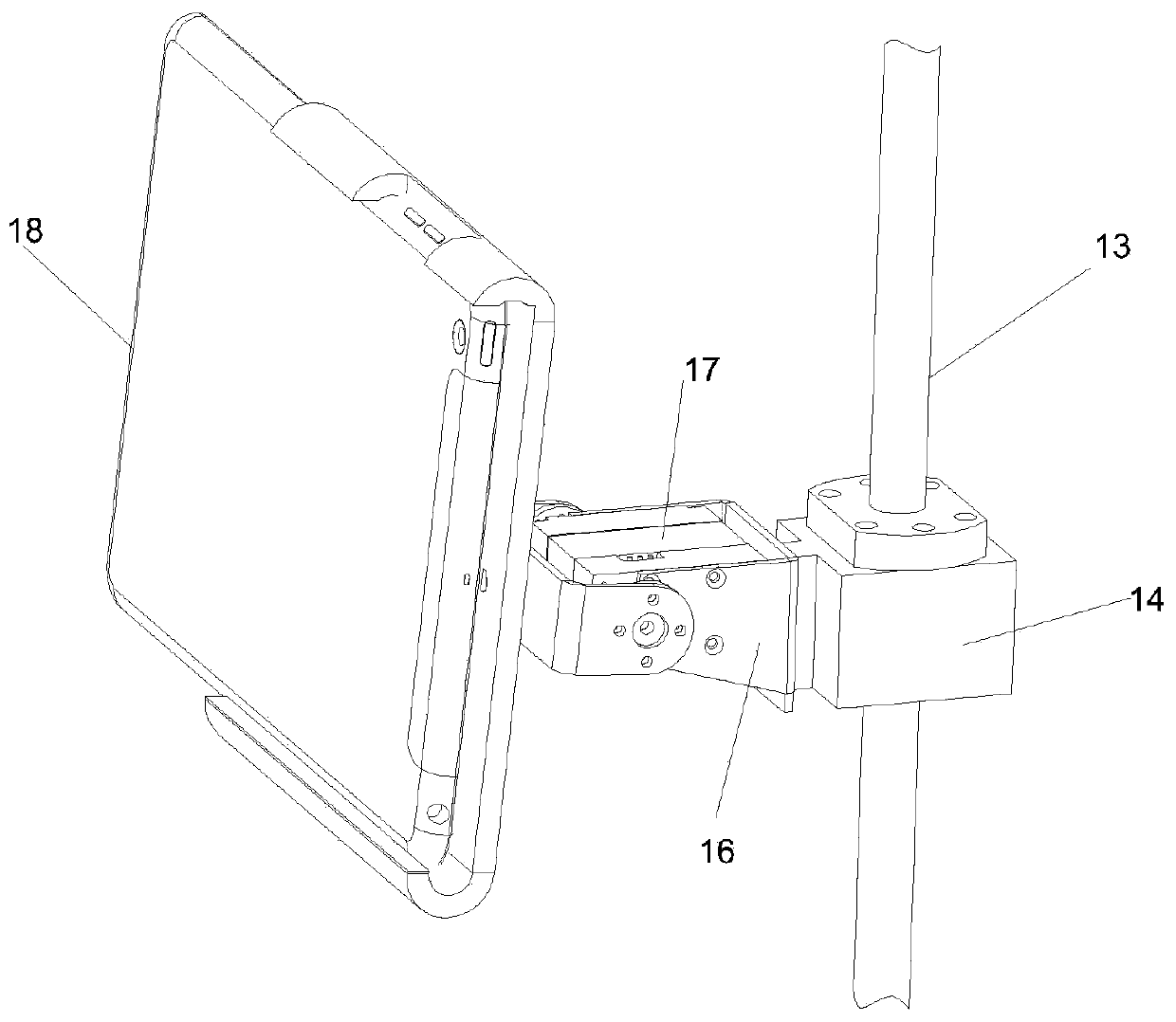

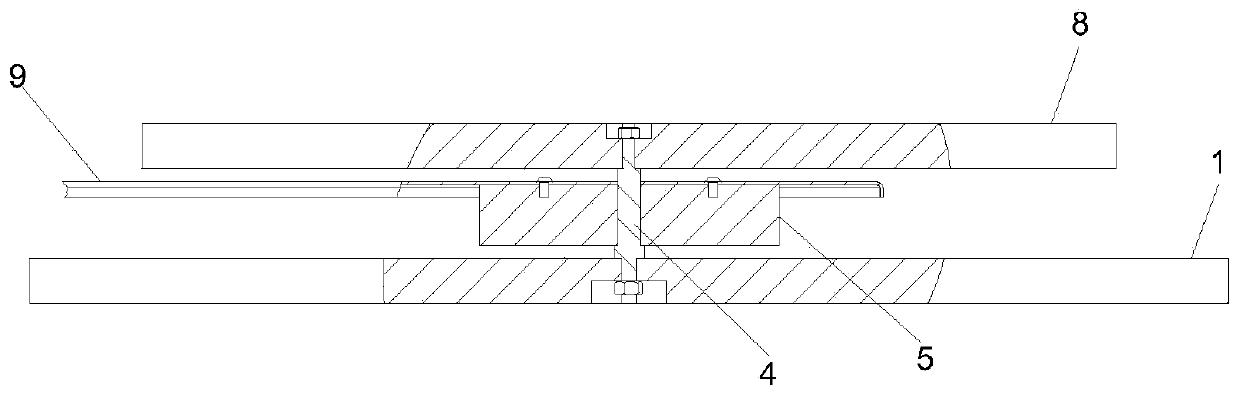

[0036] The object 24 to be scanned is placed on the center of the scanning platform 8. In the initial state, the scanner 18 assembly descends to the lower limit height, and the scanner 18 is adjusted to maintain a horizontal attitude through the steering gear 17;

[0037] 2. Start scanning:

[0038] The stepper motor 15 drives the scanner 18 components to rise up successively, and the rotating scanning member is driven by the double-axis hub motor 3 to rotate, and the pitch angle of the scanner 18 can be adjusted by the steering gear 17 according to the scanning requirements;

[0039] After the scanner 18 assembly rises up for the first time, the rotary platform 9 rotates clockwise to the position of the rotary travel switch 2, and the scanner 18 completes the first scan of the object 24 to be scanned, and transmits the scan information to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com