Automatic hydrogen storage material cycle life tester and testing method

A hydrogen storage material and cycle life technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of low test efficiency, inability to realize hydrogen storage material circulation, continuous hydrogen charging and discharging operation, etc., and achieve the effect of fully automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention and its operating process will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

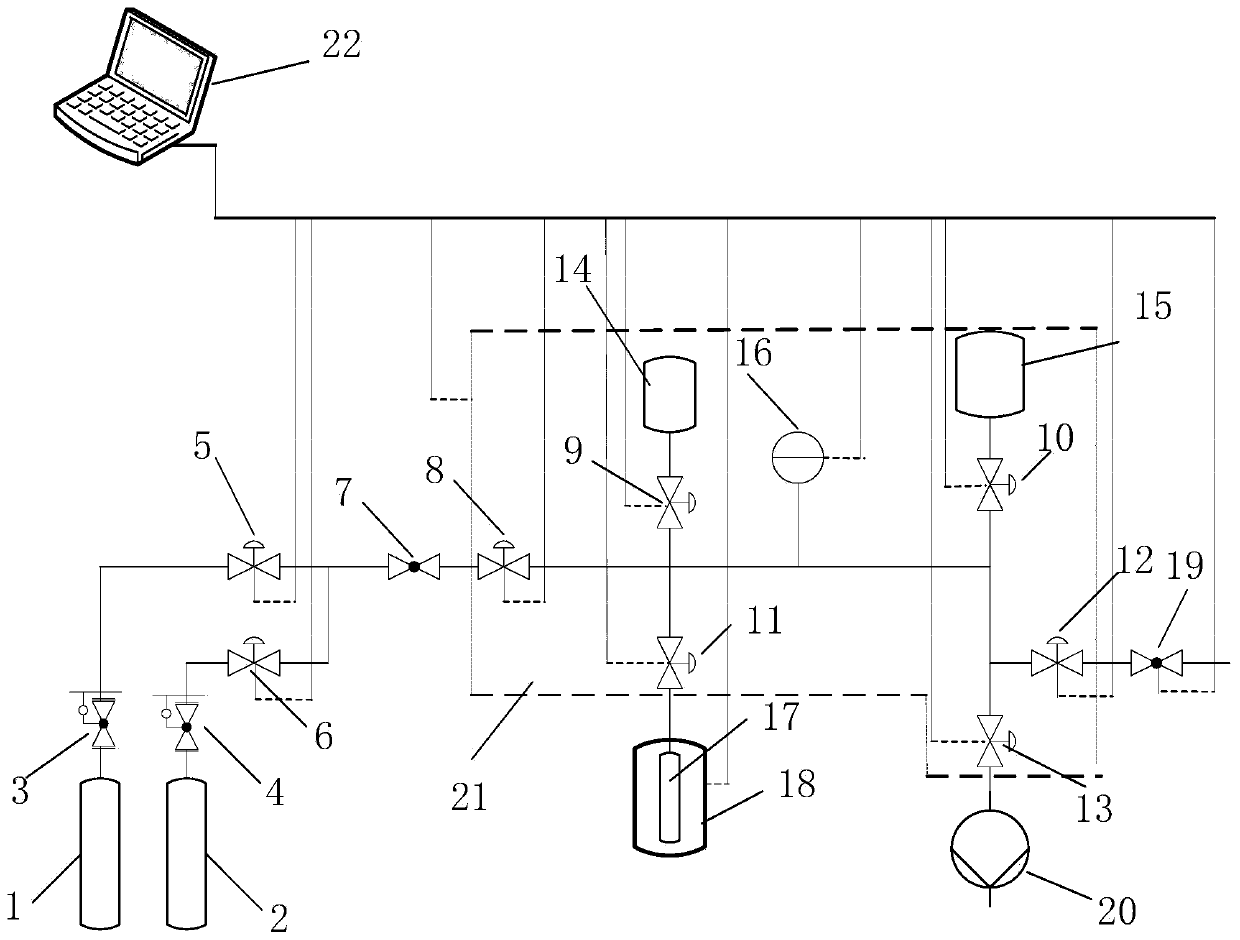

[0061] Such as figure 1 Shown is an embodiment of the present invention, including: a computer 22, an air source part, a system main body, a sample tank part, an emptying system, a temperature control system, a data acquisition system and an automatic control system; The main actuators of the hydrogen discharge process include: the first pressure accumulator 14 for storing hydrogen during the hydrogen absorption kinetic test, the second pressure accumulator 15 for storing hydrogen during the hydrogen desorption kinetic test, and the monitoring system Pressure transmitter 16 for pressure, third pneumatic valve 8, fourth pneumatic valve 9, fifth pneumatic valve 10, sixth pneumatic valve 11, seventh pneumatic valve 12, eighth pneumatic valve 13, main three-way, auxiliary Tee, main four-way and pipeline, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com