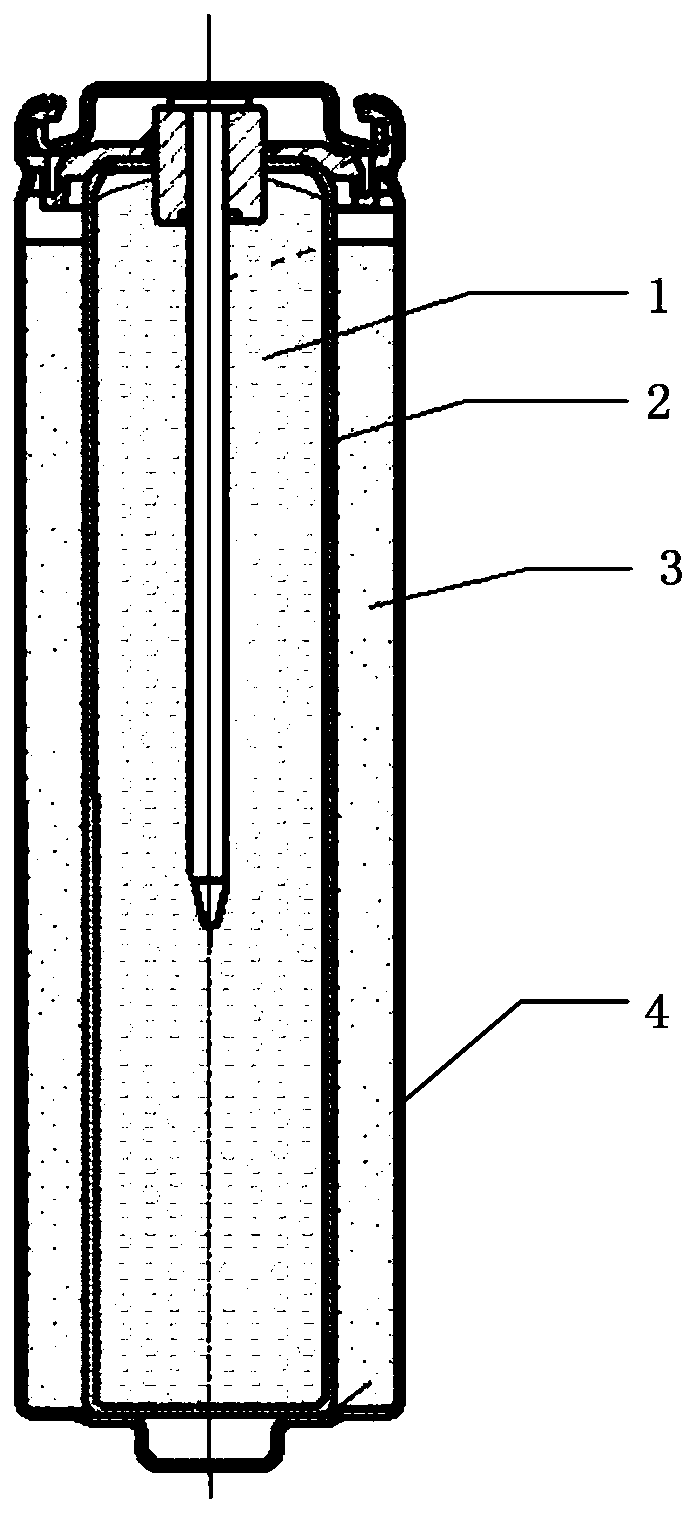

Alkaline zinc-manganese battery

A zinc-manganese battery, alkaline technology, used in primary batteries, primary battery parts, battery electrodes, etc., can solve problems such as battery performance degradation, battery conductivity deterioration, and zinc paste density reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Battery discharge method:

[0057] (1) DSC discharge simulation. The specific discharge method is as follows: the first pulse is discharged at 1500mW for 2 seconds, and then the second pulse is discharged at 650mW for 28 seconds. The pulse was repeated 10 times followed by 55 minutes of rest. This pulse and off time is then repeated until a preset cutoff voltage, which is 1.05 volts. Record the number of pulses when discharging to the cut-off voltage.

[0058] (2) Simulate motor discharge. The specific discharge method is as follows: use a 3.9 ohm load to continuously discharge the battery to the cut-off voltage, the cut-off voltage of the battery discharge is 0.8 volts, and record the discharge time of the battery.

[0059] The test of the battery is to discharge the battery after it is placed at room temperature for 1 week. The battery discharge temperature is controlled at 20±1°C.

[0060] Preparation of battery:

[0061] Mix electrolytic manganese dioxide (Xi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com