A kind of thin thermal battery separator and its preparation method

A technology of separators and thermal batteries, applied in the direction of delayed action cells, etc., can solve the problems of the diameter and size of the separators, electrolyte electrical noise, poor high-power discharge capacity, etc., to improve the high-power discharge capacity and high-power discharge capacity. Improved and easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

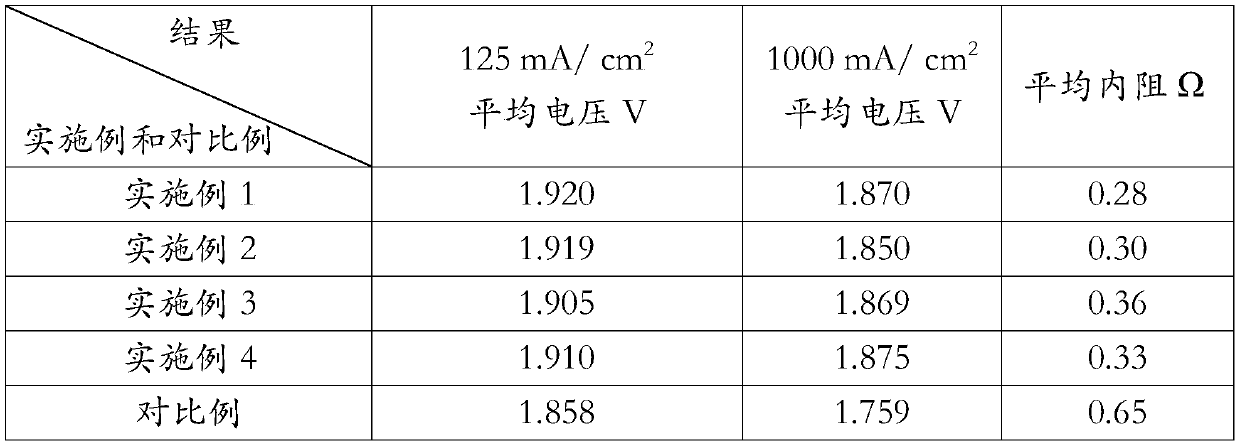

Examples

Embodiment 1

[0033] A preparation method of a thin thermal battery separator, comprising the following steps:

[0034] (1) Preparation of electrolyte molten salt: in a natural environment, put the electrolyte salt in a crucible, then transfer it to a muffle furnace, raise the temperature to 400°C, and the heating rate is 5°C / min, to obtain the electrolyte molten salt;

[0035] Wherein, the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 40%, and the mass percentage of LiCl is 60%.

[0036] (2) In the natural environment, use glass fiber as the supporting matrix, dip it in the electrolyte molten salt, keep it for 10 minutes, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 100 μm, and the pore size is 1.0 μm;

[0037] (3) In an environment with a humidity not greater than 3%, the spacer is transferred to a muffle furnace at 400°C for 10 minutes, and then naturally cooled to room temperature;

[0038] (4) In an environme...

Embodiment 2

[0040] A preparation method of a thin thermal battery separator, comprising the following steps:

[0041] (1) Preparation of molten electrolyte salt: in a natural environment, put the electrolyte salt in a crucible, then transfer it to a muffle furnace, raise the temperature to 500°C, and the heating rate is 10°C / min, to obtain molten electrolyte salt;

[0042] Wherein, the electrolyte salt is a mixture of LiCl, LiBr and KBr, the mass percentage of LiCl is 5%, the mass percentage of LiBr is 40%, and the mass percentage of KBr is 55%;

[0043] (2) In the natural environment, use glass fiber as the supporting matrix, dip it in the electrolyte molten salt, keep it for 20 minutes, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 200 μm, and the pore size is 2.0 μm;

[0044] (3) In an environment with a humidity not greater than 3%, the spacer is transferred to a muffle furnace at 350°C for 30 minutes, and then naturally cooled to room temp...

Embodiment 3

[0047] A preparation method of a thin thermal battery separator, comprising the following steps:

[0048](1) Preparation of molten electrolyte salt: in a natural environment, put the electrolyte salt in a crucible, then transfer it to a muffle furnace, raise the temperature to 450°C, and the heating rate is 8°C / min, to obtain molten electrolyte salt;

[0049] Wherein, the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 60%, and the mass percentage of LiCl is 40%;

[0050] (2) In the natural environment, the metal oxide film is used as the supporting matrix, which is immersed in the molten electrolyte salt for 30 minutes, and then taken out to obtain a separator; the thickness of the metal oxide film is 110 μm, and the pore size is 0.8 μm;

[0051] (3) In an environment with a humidity not greater than 3%, the spacer is transferred to a muffle furnace at 380°C for 20 minutes, and then naturally cooled to room temperature;

[0052] (4) In an environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com