Paired saw webs

A technology of paired saw blades and saw blades, which is applied to metal sawing equipment, knives of sawing machine devices, metal processing equipment, etc., can solve the problems of large friction area, high cost, and short service life of saw blades, and achieve processing technology The effect of simplicity, long service life and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

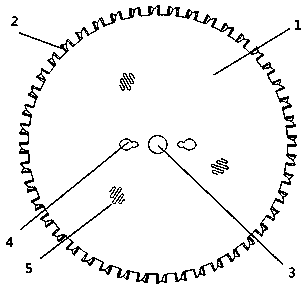

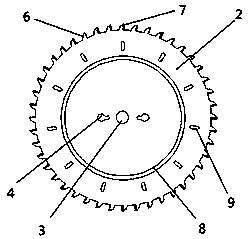

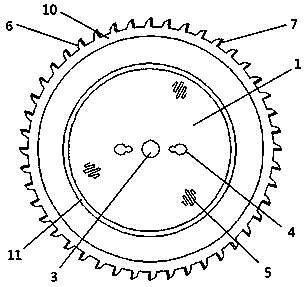

[0018] like figure 1 As shown, a pair of saw blades, the pair of saw blades include a first saw blade and a second saw blade that are coaxial and rotate in opposite directions, wherein each saw blade includes a circular base and a periphery of the base The saw teeth on the saw blade; the central axis of the first saw blade and the second saw blade are provided with installation holes of the same size; the saw teeth are provided with a superhard alloy cutter head; The head is set opposite to the superhard alloy cutter head of the second saw blade; at least three serpentine sound-absorbing lines are evenly arranged on the first saw blade; at least eight heat dissipation rows are evenly distributed around the second saw blade Chip hole: the side of the superhard alloy cutter head on the first saw blade facing the second saw blade is in contact with the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com