High sound absorption CMT reinforced polyurethane foam composite material for vehicles

A technology of polyurethane foam and composite materials, which is applied in the direction of synthetic resin layered products, film/sheet-like adhesives, layered products, etc., which can solve the problem of difficult to improve the mechanical properties of automobile bottom guards, limited applications, and mechanical properties Poor and other problems, to achieve dimensional stability and impact resistance, improve mechanical properties, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

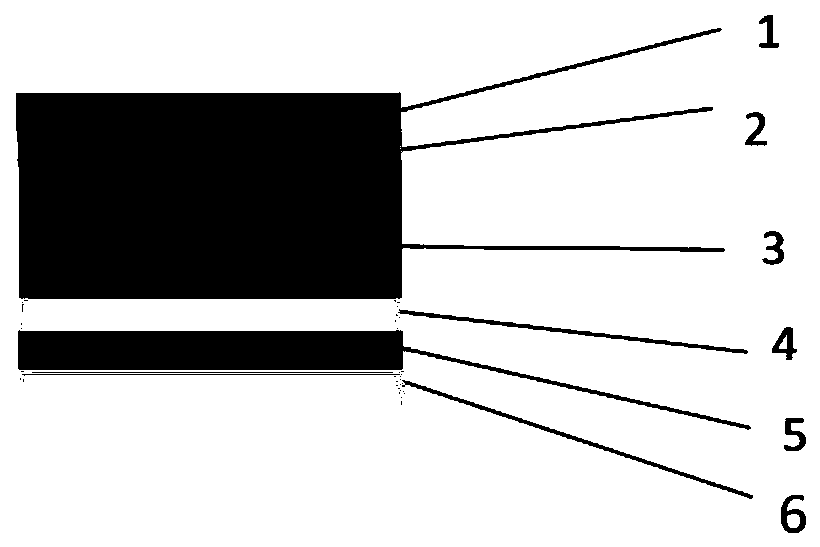

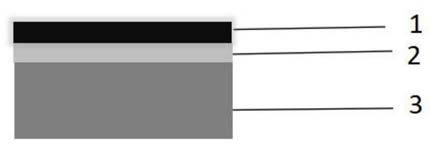

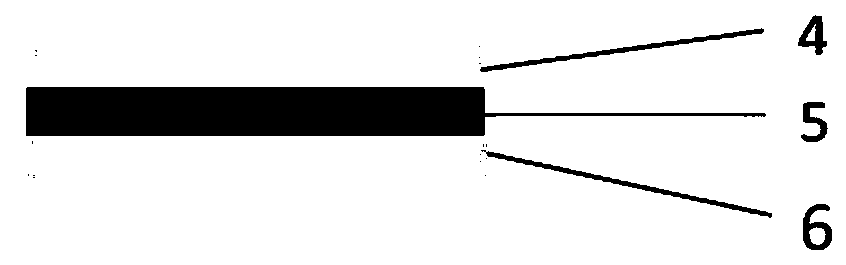

[0034] This embodiment is a high sound-absorbing CMT reinforced polyurethane foam composite material for vehicles, which is composed of a polyurethane foam composite layer for sound absorption and heat insulation and a CMT reinforced composite layer for reinforcement. Its structure from top to bottom is: polyurethane foam The composite layer includes a hydrophobic and oil-repellent layer, a breathable sound-absorbing adhesive layer, and a polyurethane foam sound-absorbing layer; a CMT reinforced composite layer includes an adhesive layer, a reinforcing layer, and an adhesive layer. The mass ratio per unit area of the polyurethane foam composite layer and the CMT reinforced composite layer is 9:5.

[0035] The air-permeable and sound-absorbing adhesive layer is a perforated hot-melt adhesive film with an area density of 70g / m 2 . The polyurethane foam sound-absorbing layer is lightweight polyurethane foam with a bulk density of 28kg / m 3 , The porosity is 95%.

[0036] The ...

Embodiment 2

[0061] This embodiment is a high sound-absorbing CMT reinforced polyurethane foam composite material for vehicles, which is composed of a polyurethane foam composite layer for sound absorption and heat insulation and a CMT reinforced composite layer for reinforcement. Its structure from top to bottom is: polyurethane foam The composite layer includes a hydrophobic and oil-repellent layer, a breathable sound-absorbing adhesive layer, and a polyurethane foam sound-absorbing layer; a CMT reinforced composite layer includes an adhesive layer, a reinforcing layer, and an adhesive layer. The mass ratio per unit area of the polyurethane foam composite layer and the CMT reinforced composite layer is 2:1.

[0062] The air-permeable and sound-absorbing adhesive layer is a hot-melt adhesive film with holes, and the surface density is 50g / m 2 . The polyurethane foam sound-absorbing layer is lightweight polyurethane foam with a bulk density of 28kg / m 3 , The porosity is 95%.

[0063] ...

Embodiment 3

[0078] This embodiment is a high sound-absorbing CMT reinforced polyurethane foam composite material for vehicles, which is composed of a polyurethane foam composite layer for sound absorption and heat insulation and a CMT reinforced composite layer for reinforcement. Its structure from top to bottom is: polyurethane foam The composite layer includes a hydrophobic and oil-repellent layer, a breathable sound-absorbing adhesive layer, and a polyurethane foam sound-absorbing layer; a CMT reinforced composite layer includes an adhesive layer, a reinforcing layer, and an adhesive layer. The mass ratio per unit area of polyurethane foam composite layer and CMT reinforced composite layer is 14:13.

[0079] The air-permeable and sound-absorbing adhesive layer is a hot-melt adhesive film with holes, and the surface density is 30g / m 2 . The polyurethane foam sound-absorbing layer is lightweight polyurethane foam with a bulk density of 25kg / m 3 , The opening rate is 96%.

[0080] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com